Green Nanotechnology for Cleaner Environment Present and Future Research Needs

E. D. Sherly1 , Kalpana Madgula1 and Rita Kakkar1

1

Department of Chemistry,

St. Francis College for Women,

Begumpet,

Hyderabad

India

DOI: http://dx.doi.org/10.12944/CWE.6.1.27

Nanotechnology is the understanding and control of matter at dimensions of roughly 1 to 100 nanometers, where unique phenomena enable novel applications. Encompassing nanoscale science, engineering and technology, nanotechnology involves imaging, measuring, modeling, and manipulating matter at this length scale. At this level, the physical, chemical, and biological properties of materials differ in fundamental and valuable ways from the properties of individual atoms and molecules or bulk matter. Nanotechnology R&D is directed towards understanding and creating improved materials, devices, and systems that exploit these new properties. It is expected to result in cleaner and less wasteful methods of manufacture, stronger and lighter building materials, smaller yet faster computers, and more powerful ways to detect and treat disease. Nanotechnology promises exciting break through and sustainable future.

This paper fundamentally covers how nanotechnology can be envisaged as a green alternative in different aspects

- nanoparticle synthesis – by green route

- Use of metal nanoparticles and nano clay as additives in polymer nanocomposites - special applications with respect to composites in packaging

- Minimizing the use of non-biodegradable plastics (thermoplastic & thermosetting) and replacing them to some extent with biodegradable plastics and biopolymers

- Tailor made applications and future needs

Copy the following to cite this article:

Sherly E.D, Madgula K, Kakkar R. Green Nanotechnology for Cleaner Environment Present and Future Research Needs. Curr World Environ 2011;6(1):177-181 DOI:http://dx.doi.org/10.12944/CWE.6.1.27

Copy the following to cite this URL:

Sherly E.D, Madgula K, Kakkar R. Green Nanotechnology for Cleaner Environment Present and Future Research Needs. Curr World Environ 2011;6(1):177-181. Available from: http://www.cwejournal.org/?p=1317

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2011-03-10 |

|---|---|

| Accepted: | 2011-04-28 |

Introduction

Nanoparticle synthesis by green route

Any chemical synthesis can be regarded as green synthesis, if it can reduce/ replace the toxic chemical substances in the form of reagents, catalysts used for the process and also by minimizing the steps involved therein, convert the waste into useful form, reduce the solvent used, use water or solvent less process. We can substitute natural or biodegradable substances in place of pure chemical substances such as starch and clay additives in plastics as reducing / capping agents in metal nanoparticle synthesis, modifying the route of chemical synthesis, employing biodegradable substances obtained from natural/synthetic sources. i.e. biocomposites, biodegradable plastics etc.

Metal Nanoparticle Synthesis

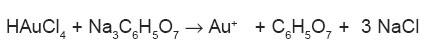

Nano particle synthesis involves both physical and chemical methods where green route can be adopted. The alternative method i.e. Synthesis of metal nanoparticles by colloidal route – involves reduction of some metal salt or acid. For example, highly stable gold particles can be obtained by reducing Chloroauric acid (HAuCl4) with Sodium citrate. The reaction takes in stages: Nucleation, condensation, surface reduction and electrostatic stabilization.

The gold nanoparticles exhibit different colours like intense red, magneta etc depending upon the particle size. In similar manner, silver, palladium, copper and other metal nanoparticles are synthesized using appropriate precursors, pH, temperature, duration of synthesis etc. Particle size, distribution and shape can be controlled by changing reaction parameters to get desired results. Alternatives to surfactants, templates or other auxillary substances that control or stabilize the nanoparticle shape during synthesis – incorporate shape controlling molecule as a function component of the final product. Gold nanoparticles above are stabilized by columbic interaction. It is also possible to stabilize nanoparticles using some thiols or capping molecules or by replacing with the capping agent that functions both as reducing and capping molecule.

A simple, green method has been developed for the synthesis of gold and silver nanoparticles by using polysaccharides as reducing/stabilizing agents. The obtained positively charged chitosan-stabilized gold nanoparticles and negatively charged heparin-stabilized silver nanoparticles were characterized with UV-vis spectroscopy and transmission electron microscopy. The results illustrated the formation of gold and silver nanoparticles inside the nanoscopic polysaccharide templates.

In another example, it was shown that by gently heating the aqueous solution of silver nitrate, soluble starch and glucose, one can synthesize starched silver nanoparticles in the 1-8 nm size range. Here glucose serves as environmetnally benign reducing agent for the metal ion and starch provides stable surface passivation to prevent the aggregation of these particles. As glucose is a mild reagent, by changing the pH and temperature, one can control the reaction kinetics.

A number of nano-gold catalysts have been prepared by depositing gold on different metal oxides (viz. Fe2O3, Al2O3, Co3O4, MnO2, CeO2, MgO, Ga2O3 and TiO2),Nano-gold supported on Fe2O3 is a highly active catalyst for low temperature oxidative destruction of methane green house gas from exhaust/waste gases. The analysis showed the presence of Au in the different oxidation states (Au0, Au1+ and Au3+) in the catalyst.

References and further reading may be available for this article. To view references and further reading you must purchase this article.

Nano-size particles of gold deposited on Fe2O3 show very high activity in the complete combustion of dilute methane. There are similar references for the high catalytic efficiency uses of metal nano particles like silver, platinum, palladium etc.

Polymer Composites with Green Additives

A composite is a combination of two or more constituent materials with significantly different physical and chemical properties which remain separate and distinct at the microscopic / macroscopic scale within the finished structure. Composites/polymers (virgin) are blended with Additives such as colorants, coupling agents, stabilizers, blowing agents, reinforcing agents/ fillers, foaming agents, lubricants and are added during processing. These additives almost makeup the 30% of the end product (resin) and are strong chemical substances. All these additives help, tailor the end product to the target area of application. The fillers can be natural or synthetic materials added to a polymer matrix to enhance its strength and other physical and mechanical properties. Some of the natural substances used as fillers are clay, starch, fibers corn waste/hemp etc. These materials are better substitutes as fillers than conventional fillers like silica, alumina etc., considering all possible combinations between polymer resin and nanofiller one can easily create a panorama of materials and potential applications in packaging, films, catalytic activity and biodegradibility of resulting nanocomposite. Main feature of polymeric nanocomposite, in contrast to conventional composites, is the reinforcement is in the order of nanometer that deeply affected final macroscopic properties. The thrust for novel materials which are biodegradable and economically viable materials to replace the more conventional materials is the triggering factor for the research in this field. Researchers are now looking for the methods to reduce the resin content of the final product, or to increase the fibre (natural/synthetic) / nanoclay or starch/clay (in case of biocomposites) content due to their biocompatibility.

Polymer Nanocomposites Matrix Resins with “Multifunctionality

They should not be considered in the near and intermediate term as a potential one-for- one replacement for current state-of-the-art carbon fiber-reinforced polymer matrix composites. The value of PNM technology is not based solely on mechanical enhancements of the neat resin. Rather, its value comes from providing value-added properties not present in the neat resin, without sacrificing the inherent processibility and mechanical properties of the neat resin. Traditionally, the preparation of a blend or composite with multifunctionality requires a trade-off between desired performance, mechanical properties, cost, and processibility. With the diversity of organic components used in wood, plastic composite processing, there is no single answer to reliably handling these potentially difficult materials.

Nanoclays as Natural Additive/Filler

Clays are hydrophilic materials and be made hydrophobic to become compatible with most of the polymers (hydrophobic). Clay for example montmorillonite organoclay is the combination of tetrahedral silicate layuers forming hexagons (SiO4 units) and octahedral alumina layer. Two tetrahedral layers sandwich the octahedral alumina layer sharing the apex oxygens with the latter. They can substitute the fillers in polymer matrix by providing stiffness, strength and flame resistance but draw backs being gas permeability and swelling in solvents.

Metal Nanoparticles as Fillers

Materials based on nanosized metals will surely represent an adequate solution to many present and future technological demands since they exhibit novel properties like Plasmon resonance, super magnetism etc. Metals undergo the most considerable property change by size reduction and their composites with polymer are very interesting application because the properties of nanosized metals (optical magnetic, dielectric and thermal transport properties) leave unmodified after embedding in polymers.

Biodegradable Plastics - Biodegradable Nanocomposites

The extraordinary success of the nanocomposite concept in the area of synthetic polymers has stimulated new research on nanocomposites based on biodegradable polymers as matrix. Biodegradable plastics are polymeric materials in which at least one step in the degradation process is through metabolism in the presence of naturally occurring organisms. Under appropriate conditions of moisture, temperature and oxygen availability, biodegradation leads to fragmentation or disintegration of the plastics with no toxic or environmentally harmful residue.

Biodegradable polymers can be classified according to their source

- Polymers directly extracted or removed from biomass i.e. polysaccharides, proteins, polypeptides, polynucleotides

- Polymers produced by classical chemical synthesis using renewable bio-based monomers or mixed sources of biomass and petroleum (i.e. polylactic acid or bio-polyester) lactic acid, the monomer of PLA is being produced from the fermentation of corn starch

- Polymers produced by micro-organism or genetically modified bacteria (polyhydroxybutyrate, bacterial cellulose, xanthan, curdian, pullan).

Thermoplastic Starch as renewable packing material

Starch is a promising raw material because of its cyclic availability from many plants, its rather excessive production with regard to current needs and its low cost. It is known to be completely degradable in soil and water and can promote the biodegradability of a non-biodegradable plastic when blended. As a packaging material, starch alone does not form films with appropriate mechanical properties unless it is first plasticized, or chemically modified. Common plasticizers for hydrophilic polymers, such as starch are glycerol and other low molecular weight polyhydroxy compounds, polyethers, urea and water. When starch is treated in an extruder by application of both thermal and mechanical energy, it is converted to a thermoplastic material. In the production of thermoplastic starches, plasticizers are expected to efficiently reduce intra-molecular hydrogen bonds and to provide stability to product properties. There are many opportunities for using starch as packaging material as films or bag, starch could be employed as packaging for fruits and vegetables, snacks or dry products.

In these applications, however, efficient mechanical, oxygen and moisture protection is needed. Thermoplastic starch (TPS) alone often cannot meet all these requirements. In particular, because of the hydrophilicity of the starch the performance changes during and after processing, due to the water content changes. To overcome this drawback, many different routes have been reported. Clay, as potential filler, has been chosen for improving the properties of TPS in such applications. It has been shown that both the tensile strength and the elongation at break of TPS were increased with the presence of small amounts (less than 5%) of sodium montmorillonite.

Poly lactic acid (PLA) biodegradable, thermoplastic from bio wastes

Lactic acid has been an intermediate-volume specialty chemical (world production <“ 40,000 tons/yr) used in a wide range of food processing and industrial applications. Lactic acid has the potential of becoming a very large volume, commodity-chemical intermediate produced from renewable carbohydrates for use as feed stocks for biodegradable polymers, oxygenated chemicals, plant growth regulators, environmentally friendly ‘green’ solvents, and specialty chemical intermediates. The recent announcements of new development-scale plants for producing lactic acid and polymer intermediates by major U.S. companies, such as Cargill, Ecochem (DuPont/ ConAgra), and Archer Daniels Midland, attest to this potential.

Poly lactic acid or polylactide is a biodegradable, thermoplastic, aliphatic polyester derived from renewable resources, such as corn starch (in the United States) or sugarcanes (in the rest of world). Although PLA has been known for more than a century, it has only been of commercial interest in recent years, in light of its biodegradability. PLA is a sustainable alternative to petrochemical-derived products, since the lactides from which it is ultimately produced can be derived from the fermentation of agricultural by-products such as corn starch or other carbohydrate-rich substances like maize, sugar or wheat.

PLA is currently used in a number of biomedical applications, such as sutures, stents, dialysis media and drug delivery devices. It is also being evaluated as a material for tissue engineering. Because it is biodegradable, it can also be employed in the preparation of bioplastic, useful for producing loose-fill packaging, compost bags, food packaging, and disposable tableware. In the form of fibers and non-woven textiles PLA also has many potential uses, for example as upholstery, disposable garments, awnings, feminine hygiene products, and nappies.

Polyhydroxybutyrate (PHB) is accumulated by a large number of bacteria as energy and carbon reserves. Due to its biodegradability and biocompatibility this bio-polyester may easily find industrial application. PHB is a typical highly crystalline thermoplastic with a very low water vapour permeability which is close to that of low density polyethylene (LDPE). The major drawback for the commercial use of the PHB homopolymer is represented by an unfavorable ageing process.

Potentially, PLA and PHB offer numerous opportunities in packaging applications. They can be formed into films or used to make moulded objects. In addition, they are compatible with many foods, such as dairy products, beverage, fresh meat products and ready meals. So far, the large-scale use of biodegradable polyesters (PHB, PLA) as packaging material is hampered by their high cost as well as their low performances.

Legal and ethical barriers and controversies Nanotechnology has an extremely high potential to benefit society through applications in food packaging. It can make the products cheaper and the production more efficient. Producing less waste and using less energy. However, any new technology carries an ethical responsibility for wise application and the recognition that there are potential unforeseen risks that may come with the tremendous positive potential. In parallel to the technical evolution of nanotechnologies, it is expected that there will be new regulatory directives and guidelines to accommodate nanotechnology based products. At present no government has developed any regulatory regime, specifically referring to the production and application of nano-particles. Also in the frame of chemical legislation, particle size does not play a role for the registration of new substances. A lot of new knowledge has to be generated on how nano-material based processes and products may interfere with human health before any regulation in this field can be established. Despite this lack in knowledge, a handful of food and nutrition products containing invisible and un-labeled nanoscale additives are already on supermarket shelves. In addition, a number of pesticides containing nanoscale materials have been released in the environment and are commercially available With respect to nano-fillers mentioned, it is important to point out that the majority of the works present in literature make use of additives and surfactants in order to increase the compatibility between the polymer and the filler. Except for specific product developed by few companies around the world, these additives are not food contact approved as yet.

Summary

Nanocomposites concept represents a stimulating route for creating new and innovative materials, also in the area of natural polymers. Materials with a large variety of properties have been realized, and even more are due to be realized. The nanocomposite materials obtained by mixing natural polymers and sheets of crystalline solid layered (clays or LDHs), offer a great variety of property profiles. They are even able to compete, both in price and in performance, with synthetic polymeric materials in packaging. In spite of the great possibilities existing for packaging in bio-based nanocomposite materials, the future scenario is difficult to predict. At this stage, we can only imagine that simple traditional packing will be replaced with multi-functional intelligent packaging. The next generation of packaging materials will be able to fit the requirements of preserving fruit, vegetable, beverage, wine and other foods. By adding appropriate nano-particles, it will be possible to produce packages with stronger mechanical, barrier and thermal performance. To food safety, nano-structured materials will prevent the invasion of bacteria and micro-organisms. Embedded nano-sensors in the packaging will alert the consumer if a food has gone bad. However, it is clear that the enthusiasm for such nanomaterial systems must be placed against the backdrop of the proper considerations of safety for the consumers and the health-care workers, and in the context of stringent regulatory approval perspectives.

According to Indian National Environment Policy 2006 the dominant theme of this policy is that while conservation of environmental resources is necessary to secure livelihoods and well-being for all, the most secure basis for conservation is to ensure that people dependent on particular resources obtain better livelihoods from the fact of conservation than from degradation of the resources. It stresses the two-way linkages between poverty and environmental quality.

References

- B.Sreedhar et al, Journal of Applied Polymer Science (2007).

- Adapted from Dahl, J.A.;Maddux B.L.S;Hutchison, J.E. “Toward Greener Nanosyntheisis” Chem. Rev. (2007).

- P.Ravindran et al, Green Chem., 8: 34-38 (2006).

- “Nanotechnology” by Sulabha kulkarni.

- Van der Walle, Buisman, Weshuis, & Eggink, (2000).

- Moore, 2004; Paull, Wolfe, Hebert, & Sinkula (2003).

- Doi & Steinbuechel, 2002; Kaplan, 1998; Mohanty, Misra, & Drzal, 2005; Steinbuchel, (2003).

- Krochta & De Mulder-Johnston (1997).

- Chemical Engineering & Process Development Division, National Chemical Laboratory, Pune, India.