Effect of Enzyme Treatment on Recycling of Shredded Currency Waste of RBI for Making Handmade Paper

Ashish Khandelwal1 * and Sunita Chauhan1

DOI: http://dx.doi.org/10.12944/CWE.6.1.10

Enzymatic recycling process of shredded currency waste was conducted at Kummarappa National Handmade Paper Institute Jaipur. The present study was aimed at recycling of shredded currency waste of Reserve Bank of India in the form of good quality hand made paper and products. Kummarappa National Handmade Paper Institute has already developed a simple technology for currency recycling. An effort was made to utilize blend of certain microbial enzymes for the recycling of shredded currency waste. It was observed that with the application of identified enzymes, a better quality pulp could be produced as compared to the conventionally produced pulp. Therefore, the enzymatic route of recycling the shredded currency waste of RBI for making handmade paper and products was found to be very useful. The tag of “Bio-processing”/enzymatically processed handmade paper” might help in improving the competitiveness of the Indian handmade paper industry especially in the international markets.

Copy the following to cite this article:

Khandelwal A, Chauhan S, Parihar S, Dixit P, Kumar S.R. Effect of Enzyme Treatment on Recycling of Shredded Currency Waste of RBI for Making Handmade Paper. Curr World Environ 2011:6(1);77-85. DOI:http://dx.doi.org/10.12944/CWE.6.1.10

Copy the following to cite this URL:

Khandelwal A, Chauhan S, Parihar S, Dixit P, Kumar S.R. Effect of Enzyme Treatment on Recycling of Shredded Currency Waste of RBI for Making Handmade Paper. Curr World Environ 2011:6(1);77-85. Available from: http://www.cwejournal.org/?p=1281

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2010-12-11 |

|---|---|

| Accepted: | 2011-01-13 |

Introduction

The continuously growing paper manufacturing industry imposes a severe demand on green plants that forms the basic raw material of papermaking. Woody and non woody plants are major sources of raw material for making paper. In mill sector, woody perennial trees (hard wood and soft woods) are mainly utilized for papermaking. Apart from these plants, rice straw and wheat straw are also the alternative raw materials for paper industry but the quality of these straw papers is very poor. Due to the increased literacy rates, the use of paper is also increasing day by day and thereby resulting into the higher demand of paper in the country. So the ultimate effect is reflected on the wood-based raw materials i.e. green cover or the forest area of the country. Recycling of used paper is another alternative that can liberate this stress from forest and the environment which gets affected due to the usage of large amount of chemicals in processing of the woody raw materials for making paper.

When we look at the handmade paper sector, we can see that it never uses wood rather it utilizes traditionally the cotton hosiery waste as a raw material and sometimes the non woody, herbaceous and annual plants for making the handmade paper. With the growing demand of handmade paper, there is a problem of raw material shortage in the case of hosiery waste which is also getting costly due to the increased efficiency of textile mills. Therefore, the need of alternate sources of raw materials is being realized in the sector. With the extensive R&D efforts carried out by Kummarappa National Handmade Paper Institute (KNHPI) Jaipur in the recent past, it has been found that the lignocellulosic raw materials like bast and leaf fibers could be the suitable option for making handmade paper. Besides this, recycling of the waste handmade papers or the trim of handmade paper is also an option for the sector.

Shredded currency waste of RBI which is nothing but a kind of waste paper and which is abundantly available in the country from the major branches of RBI has proved to be a good source of alternative raw material for making a good quality handmade paper and board.

Thus recycling of used paper appears to be a good alternative both for the mill sector and for the handmade paper sector. Already, there are certain waste paper based mills in India which are using the waste and used paper from the domestic and international regions for making varieties of paper and paperboard. But in the context of present day quality-consciousness, this recycling industry is in search of new technologies which can improve the quality, reduce the production cost and can be accommodated easily into the existing process design. Recent research with enzymes showed that enzymatic de-inking might be an alternative solution of effective recycling of the waste paper. Therefore, the present study aims to work out a suitable enzymatic option for recycling of the shredded currency waste of RBI.

Review of Literature

Bamboo was the traditional fibre resource and was in use since early 20’s and continued to be the main raw material for paper making till end of the 60’s. only in early 70’s due to change in govt. policy a number of small mills were established with installed capacity ranging from 21t/d to 30t/d based on agricultural residues and waste paper to meet the domestic demand of paper.

In the recent years, the environmental concerns of our society have overtaken the industry all over the world and the concept of eco-paper is gradually holding its roots. The public has become more demanding about the environmental aspects and are ready to sacrifice the quality of products to save the environment. World over the pulp and paper industry in looking for alternatives for its existence, waste paper recycling was found to be more suitable over the other alternatives like utilization of agricultural residues having some limitations with respect to availability and usage.

The non-wood fibers particularly bagasse and recycled fiber occupy a pivotal position in bridging the gap between demand and supply of raw materials. However, due to fluctuations in the price of market pulp and waste paper prices, there is a need to control waste paper prices as its utilization is considered as one of the important way to conserve the cellulosic fiber at a time when natural resources are depleting( Kulkarni,2001).

Today, 90% of paper pulp is made of wood. Paper production accounts for about 35% of felled trees, (Martin, 2004) and represents 1.2% of the world’s total economic output. (FAO, 2004) Recycling of newsprint saves about 1 tonne of wood while recycling 1 tonne (1.1 ton) of printing or copier paper saves slightly more than 2 tonnes of wood. This is because Kraft pulping requires twice as much wood since it removes lignin to produce higher quality fibers than mechanical pulping processes. Relating tonnes of paper recycled to the number of trees not cut is meaningless, since tree size varies tremendously and is the major factor in how much paper can be made from how many trees. (Marcot, 1992.) Trees raised specifically for pulp production account for 16% of world pulp production, old growth forests 9% and second- and third- and more generation forests account for the balance (Martin, 2004). Most pulp mill operators practice reforestation to ensure a continuing supply of trees. The Forest Stewardship Council (FSC) certifies paper made from trees harvested according to guidelines meant to ensure good forestry practices. It has been estimated that recycling half the world’s paper would avoid the harvesting of 20 million acres (80,000 km²) of forestland. (Berkeley, CA: 1990).

Energy consumption is reduced by recycling, although there is some debate concerning the actual energy savings realized. The EIA claims a 40% reduction in energy when paper is recycled versus paper made with unrecycled pulp (Energy Information Administration, 2006). While the Bureau of International Recycling, BIR, claims a 64% reduction. Some calculations show that recycling one ton of newspaper saves about 4,000 KWh of electricity. Recycling paper to make pulp may actually consume more fossil fuels than making new pulp via the Kraft process, however, since these mills generate all of their energy from burning waste wood (bark, roots) and byproduct lignin. (Jeffries, 1997). Pulp mills producing new mechanical pulp use large amounts of energy; a very rough estimate of the electrical energy needed is 10,000 megajoules (MJ) per tones of pulp (2500 KWH per ton), (Biermann & Christopher, 1993). usually from hydroelectric generating plants.

About 35% of municipal solid waste (before recycling) by weight is paper and paper products. (US Environmental Protection Agency, 2005). Recycling 1 tonne of newspaper eliminates 3 cubic meters of land filll. (Sudbury, 1989).

In the recent years, world wide the use of waste paper in pulp and paper production has made a tremendous growth. World waste paper consumption has increased from about 50 million tons in 1982 to about 100 million tons in 1994 and is expected to grow to almost 200 million tones by the year 2010. Since 1990, the consumption of waste paper in Asian countries has increased from 15 million tons to 22 million tons. The world average for waste paper recovery is about 35% with Japan having highest recycling rate (about 56%) the potential use of waste paper is evident from the fact that mills in south Korea and Taiwan are dependent on waste paper as a raw material to the extent of about 90%. Around 14% of the world’s waste paper consumption is traded internationally of which 50% in provided by US (Kulkarni, 2001).

The recycling rate of India is very low (39.5%) as compared to the countries like Malaysia (83.9%) or Nether land (73.7%). Due to lack of proper segregation of the waste paper at source and import of the same at higher prices might be the reason behind this. Beside this, the recycling rate is generally low when a high quality paper is being utilized as a source of waste paper. Due to lack of proper technology of recycling such waste papers are not completely utilized (Tandon et. al, 2001).

Most important application among these are the use of enzymes as an aid to pulping, bleaching and papermaking with an aim of reducing the requirement of cooking and bleaching chemicals, energy during pulping and refining, management of wood and waste minimization (Chauhan et al, 2008).

Indian handmade paper industry contributes to less then 0.5 % of the total countries production of paper & paper board till the year 2005-06 & this share has recently increased to nearly 0.7 %. since the production of hand made paper. Which was nearly 25000 tones in the year 2005-06 now stands at nearly 50,000 tons (Jain & Sharma, 2007).

Material and methods

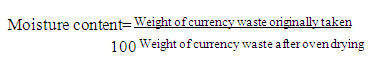

Moisture Determination in the Raw Material (SCW)

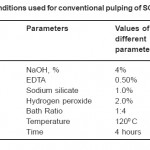

Conventional Process for Recycling the Shredded Currency Waste

The conventional process of conversion of shredded currency waste into handmade paper and products utilizes pressurized digestion using Sodium hydroxide as the pulping chemical under the conditions given in table-4. Pulping process is shown in Fig.7.

|

Conditions used for conventional pulping of SCW Click here to View table |

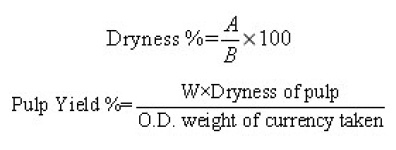

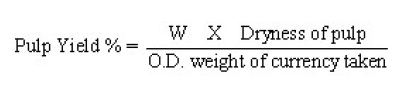

Yield Determination of Pulp

The pulp yield was determined by weighing the pulp (‘w’ total AD weight of pulp) & taking two representative samples each of 2-3 gm in two clean Petri dishes for determining the dryness (dry content per 100gm AD weight). The weighed samples were then dried in a Hot air oven at 102 + 20C for an overnight. The dried samples were then weighed & pulp yield was determined as follows.

A → Weight of pulp obtained after oven drying

B → A.D. weight of pulp originally taken for dryness W → Total A.D. weight of the pulp

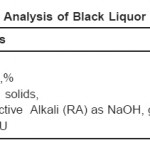

Black Liquor Characterization

Black liquor obtained from the pulping process was characterized for the parameters including total solids, pH, colour, RAA, suspended solids.

pH of the black liquor

Was measured using the pH meter after proper calibration with the standard buffer solutions of pH -4, pH -7 and pH -9.2. For this, the liquor was taken out from the cold store and left for sometime so as to attain the room temperature and then shaken well for mixing. After mixing, pH electrode was immersed into the liquor to note its pH value.

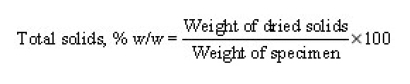

Total solids in black liquor

For estimating the total solids in black liquor obtained, 10 to 20 g of it was weighed in glass petri dishes and kept in the oven at 1050 C for the overnight. Then the dried contents were weighed to the constant weight. The Petri dishes were cooled in desiccator before weighing. Empty dish weight was also taken.

Calculation

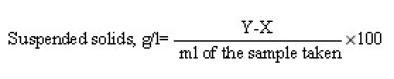

Suspended Solids in Black Liquor

Two sets of previously weighed centrifuge tubes were taken. 50ml of well-shaken black liquor was put in each tube and centrifuged them for about 20 minutes at 10,000 rpm. Then the supernatant black liquor was taken out and the pellet was given a single washing with distilled water. The tubes were then dried at 1050C in a hot air oven and the O.D. wt. was recorded. Suspended solids were calculated as per the formula given below:

| Calculation | |

| Wt. of empty tube (oven dried) | = X g |

| Wt. of residue in tube (oven dried | = Y g |

| Wt. of residue | = Y-X g |

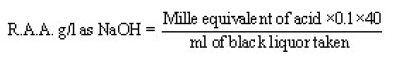

Residual Active (RA) Alkali in Black Liquor

For determining the Residual Active Alkali (RA) in black liquor, the measured volume of black liquor was taken in a small beaker and its pH was noted with the pH meter. The liquor was then titrated with 0.1N HCl to a pH of 7.0. The titrant was added in increment of fixed volume, pH was recorded after each addition and continuous mixing of the solution was done. Titrant was added drop wise during the later stages so as to avoid its over-addition.

Calculation

Colour was measured spectrophotometrically using the Elico make UV/Vis. Spectrophotometer (SL-164). For this, suitably diluted sample of black liquor was tested for its absorbance at 465 nm. Colour of the solution was calculated using the formula given below: 0.41 abs.= 500 PCU

Value of the Colors was Reported in Platinum Cobalt Units (PCU).

Beating/Refining

The washed pulp obtained from the digester was subjected to the beating process. The degree of beating was controlled through the CSF measurement. The obtained pulp was beaten to a CSF value of 300 ml.

Canadian Standard Freeness (CSF) Method

A disintegrated pulp sample was diluted to a stock concentration of 0.3 + 0.002 %. The funnel & drainage chamber was cleaned and the drainage chamber was placed in position. The receiving funnel was placed in a position as the recipient of the discharge from the side orifice. While stirring, 1000 + 5ml of homogenous pulp suspension was transferred in a clean graduated cylinder. Bottom of the chamber was closed followed by opening of the lid & air cock. Five seconds were allowed to elapse from the time of pouring the stock & then opened the air lock to start the flow. When the discharge from the side orifice was stopped, volume of this discharge was noted and reported as the CSF value of the pulp.

Sheet Making

The test sheets were prepared using the sheet former method. For this, the beaten pulp was disintegrated and the stock obtained was diluted to a concentration of 0.2 to 0.5 % and its consistency was determined.

Sheet Forming

The drain valve was closed. The inlet valve was opened to wash the wire. The upper section was clamped in position. When the water rose to 50 mm above the wire screen, the amount of stock was added to a grammage of sheet 60.0 +3.0 g/m2 calculated on an oven dry basis. The water was mixed with suspension and filled up to the mark. By inserting the stirrer and moving it briskly up and down six times and slowly withdrawing the stirrer. After 10 seconds, the drain valve was opened. When the water left the wire screen, the sheet was formed. The two blotters were placed wire side up over the sheet on the wire. The couch weight was placed gently on the blotter and the roll was moved backwards and forwards across the plate. Five complete rolls were made in 20 sec. and the couch roll was lift up from the middle of the plate the test piece was carefully separated.

Pressing

The laboratory sheet was placed to the couch blotter and on the top, one dry blotter was placed for pressing. The drying plate was placed on top of the test piece with its polished side facing down. The sheets were placed in the press. The pressure on the sheet was 410+10 kpa with in 20 + 10 sec. This pressure was maintained for 5 min.+ 15sec. and the pressure was then released (1st pressing stage). The sheets were again placed in the press and pressed to 410 + 10kpa. The pressure was maintained for 2min. + 15sec., then released and the sheets were removed from the press (2nd pressing stage).

Drying

The sheets were kept at normal air circulation for an overnight period. For this, thesheets attached on the drying plates were kept on the drying rings. The sheets were then separated from the drying plates. The sheets should not shrink during drying.

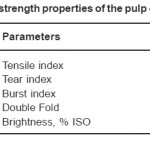

Analysis of Optical and physical strength properties of the pulp

The hand sheets prepared were got tested in the Paper-testing laboratory for the following parameters using the standard test methods as given below:

|

Conditions Utilized for Enzyme Treatment Click here to View table |

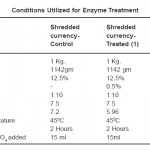

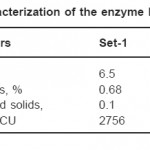

Enzymatic Treatment of the Shredded Currency Waste

For this, measured amount (on OD basis) of the shredded currency waste was taken and transferred into the Hydra pulper. Heating was started. When temperature reached to 450C, 4N H2SO4 was added to bring the pH to 6.0. The enzyme solution (including a mixture of cellulases/ hemicellulases) was added to the hydrapulper. It was then kept for 2 hours with intermittent mixing. Conditions of enzyme treatment are given below.

The enzyme liquors were collected from the hydrapulper for analysis of total solids and colour, pH as given previously. After the enzymatic treatment of the shredded currency waste, it was washed thoroughly and processed similarly as before.

|

Analysis of Black Liquor Click here to View table |

Results

Conventional Process

The conventional process of conversion of shredded currency waste into handmade paper and products was carried out as detailed in the methodology part.

Black Liquor Analysis

Black liquor obtained from the conventional pulping process was characterized for all the important parameters as given in table.

Pulp Yield

Yield of the pulp obtained was also calculated as given below:

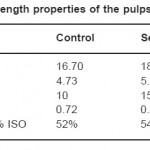

Physical Strength Properties of the Pulp Obtained

|

Table 1: Click here to View table |

Physical strength properties of the pulp obtained

Were determined by testing the hand sheets of 60 gsm prepared in the sheet former for the various parameters. (Table-8)

|

Characterization of the enzyme liquors Click here to View table |

Enzymatic Treatment of the shredded currency waste

was carried out as described earlier. The currency waste was washed thoroughly after the enzyme treatment and analysis of the enzyme liquor generated is as below

Pulp Yield

|

Physical strength properties of the pulps obtained Click here to View table |

On evaluating the physical strength properties of the pulp obtained after enzyme treatment of the shredded currency waste of RBI, it was found that all the parameters were higher than the control. Brightness value was also found to be more and it further increased with the increase in dosage of enzyme because second set showed a gain of five points as compared to the control pulp (Table-10).

Thus a good quality handmade paper could be developed from with help of enzyme from shredded currency waste of Reserve Bank of India; the paper thus developed can be used to make the product of value added item like File Covers, Carry Bags, Pan Stand, Photo Frames etc.

Discussion

Enzyme treatment of papermaking fibers has been a topic of increasing interest in the last few years. Cellulases and hemicellulases are the principal enzymes used for fiber modification. It has been reported in literature that the modification of secondary fiber with cellulases and hemicellulases can result in a substantial increase in pulp freeness with little or no loss in physical properties.

In the present study, a gain in brightness points has been obtained in the pulp obtained from the enzymatically treated shredded currency waste of RBI besides an improvement in the strength properties. It was also observed that the benefits of enzyme treatment were increasing with the increased dosage of enzyme because better results were obtained in set-2 than the set-1.

The findings of the present study are in concurrence with the earlier reports available in the literature. Ow and Bom(1990) and Kim et al (1991) have reported an enzymatic deinking method for old newsprint and white ledger using cellulases. Enzymatically deinked fiber had higher freeness, better drainage characteristics and higher mechanical strength properties than fibers from a conventional deinking process. They also observed a decrease in pulp disintegration time, which was attributed to an attack on interfiber bonding areas through partial enzymatic hydrolysis or partial depolymerization of carbohydrates on the fiber surface (Jackson etal, 1993). Oltus et al (1987) have also investigated enzymatic hydrolysis of various types of waste paper to reverse hornification and regain the fiber surface activity of the original fiber. Pommier et al (1989) have also reported an enhancement in strength of secondary fiber by enzymatic treatment. For all these effects, it has been suggested that the enzymes act on the surface of fibers producing a peeling effect. If the peeling effect is controlled, the enzymes will remove only some very small components that have a great affinity for water, but do not contribute to the hydrogen bonding potential of the fiber. Thus better drainage of the pulp is allowed without affecting mechanical properties. Therefore, increase in brightness value and strength properties of the pulp prepared from enzyme-treated shredded currency waste obtained in the present study are in accordance to the previous findings.

It can be concluded from the present study that the enzyme treatment of the shredded currency waste of RBI is very effective in its recycling for making handmade paper in terms of the improvement in brightness and strength properties of the pulp produced. In addition to this, it was found that all the properties showed an increasing trend with the rising dose of enzyme. Therefore, to get a brightness equivalent to the control pulp, a less amount of pulping chemical might be sufficient and thereby a possibility of saving the chemicals used. As a result, the quality of effluents also improves and a better quality handmade paper can be produced by incorporating an enzymatic treatment stage in the conventional process of recycling the shredded currency waste of RBI. Thus, utilization of biotechnology in processing of shredded currency waste would help in improve in the environmental status of the Indian handmade paper industry besides addressing the problem of global warming and solid waste disposal.

References

- Baird, Colin, Environmental Chemistry (3rd ed.) p. 512. W. H. Freeman ISBN 0-7167-4877-0; Recycling in Ohio (2004).

- Biermann, Christopher J., Essentials of Pulping and Papermaking. San Diego: Academic Press, Inc (1993).

- Chauhan, S., Khan, M.E., sharma, A.K., and Jain, R.K.,“Enzymatic pulping of shredded currency waste : A potential fiber resources for hand made paper industry Abstract volume of the National conference on “Application of Biotechnology in sustaining the environment” organized by International Collage for Girls and Indian Science Congress Association (region office, jaipur) during 5-6 feb. 08 (page-16) (2008).

- Berkeley, CA The Recycler’s Handbook : The EarthWorks Press (1990).

- Hershkowitz, A. Bronx ecology. Washington DC: Island Press. p. 62 (2002).

- Howsam, Leslie (1991). Cheap Bibles: Nineteenth Century Publishing and the British and Foreign Bible Society. Cambridge University Press. ISBN 10: 0521522129.

- Jeffries, Tom (March 27, 1997). Kraft pulping: Energy consumption and production. University of Wisconsin Biotech Center, Retrived on 2007-10-21.

- Jensen, Timothy (April 1999). Packaging Tapes: to Recycle of Not. Adhesive and Sealants Council, Retrieved on (2007).

- Jain, R.K., sharma, A.K., Kumar, A., Khan, M.E., Agarwal, S., and Chauhan, S. “Improved Process for Conversion of SCW into Different Varieties of Handmade Paper” Paper published and circulated during the 3-days national level workshop “Utilization of SCW of RBI for HMP” from 14 - 16 may 07 organized by KNHPI at Jaipur (2007).

- Jain,R.K, & Sharma A.K., “ Indian Handmade paper industry prospects & respectness “ sovenia published the internationalconference on pulp & paper (PAPEREX-07 held at Delhi during Dec.07: 21-28 (2007).

- Kulkarni A.G. “Utilization of Recycled Fiber –An Overview” 2001. Interaction Meet of Recycled Fiber in paper & Newsprint 12th April (2001).

- MacFadden, Todd; Michael P. Vogel, Facts About Paper. Printers’ National Environment Assistance Center, Montana State University. Retrived on 2007-10-30 (1996).

- Marcot, Bruce G. (1992). How Many Recycled Newspapers Does It Take to Save A Tree. The Ecology Plexus. Retrieved on 2007-09-22.

- Seiter, Pikulin, (Oct 1998). Environmentally benign USPS stamps. TAPPI Pulping Conference. Retrieved on 2007-11-08.

- Sudbury, Jodi B. (1989). 50 Simple things you can do to Save the Earth. Berkeley CA: Earthworks Press. ISBN 0929634063.

- Tandon R., Mathur, A.G. Kulkarni, “Practices Prevailing in Collaction Sorting and Grading of Recovered Paper- A Comparison” 2005 IPPTA Journal (No.3) Page 93-94).

- Tandon R., Thakur V.V., Mohd. H. Chisty, R.M. Mathur. and A.G. Kulkarni, “Enzymatic Deinking An Alternative Technology for Quality Upgradation of Mix Office waste” 2005 IPPTA Journal (No.3) Page 51-52).

- Tandon R., R.M. Mathur, Manju Prajapati, and A.G. Kulkarni “Recovery and Reuse of Waste Paper in Indian Paper Industry” Interaction Meet of Recycled Fiber in paper & Newsprint 12th April 2001.