Performance evaluation of effluent treatment plant of dairy industry

Dipali H. Chaiudhari1 * and R.M. Dhoble1

1

G.H. Raisoni College of Engineering,

Nagpur,

India

DOI: http://dx.doi.org/10.12944/CWE.5.2.26

Dairy industry is among the most polluting of the food industries in regard to its large water consumption. Dairy is one of the major industries causing water pollution. Considering the increased milk demand, the dairy industry in India is expected to grow rapidly and have the waste generation and related environmental problems are also assumed increased importance. Poorly treated wastewater with high level of pollutants caused by poor design, operation or treatment systems creates major environmental problems when discharged to the surface land or water. Various operations in a dairy industry may include pasteurization, cream, cheese, milk powder etc. Considering the above stated implications an attempt has been made in the present project to evaluate one of the ETP for dairy waste. Samples are collected from forth points; Raw effluent [P-1], Equalization tank [P-2], Aeration tank [P-3], Oxidation ditch [P-4] to evaluate the performance of ETP. Parameters analyzed for evaluation of performance of ETP are pH, COD, BOD at 27° C, TSS. The COD, BOD at 27° C and TSS removal efficiency of ETP were 94 %, 95%, 93% respectively.

Copy the following to cite this article:

Chaiudhari D. H, Dhoble R. M. Performance evaluation of effluent treatment plant of dairy industry. Curr World Environ 2010;5(2):373-378 DOI:http://dx.doi.org/10.12944/CWE.5.2.26

Copy the following to cite this URL:

Chaiudhari D. H, Dhoble R. M. Performance evaluation of effluent treatment plant of dairy industry. Curr World Environ 2010;5(2):373-378. Available from: http://www.cwejournal.org/?p=1234

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2010-09-09 |

|---|---|

| Accepted: | 2010-10-28 |

Introduction

Waste water generated in a dairy contains highly putrescible organic constituents. This necessitates prompt and adequate treatment of the waste water before its disposal to the environment. Almost all the organic constituents of dairy waste are easily biodegradable. Hence the wastewater is amenable to biological treatment-either aerobic or anaerobic.1 Rapid growth of industries has not only enhanced the productivity but also resulted in the production and release of toxic substances into the environment, creating health hazards and affected normal operations, flora and fauna. These wastes are potential pollutants when they produce harmful effects on the environment and generally released in the form of solids, liquid effluents and slurries containing a spectrum of organic and inorganic chemicals.2

Effluent treatment in industries to meet the discharge standards mentioned by CPCB has always been a great problem for the industrialists. Every industry effluent treatment plant needs to treat the effluent for this purpose in their own industry via effluent treatment plants. Before discharging the treated effluent on to the land or any surface water body the industries should meet the effluent discharge standard norms.3 In order to have proper processes in the ETP, Characterization of waste water, treatability studies and planning of proper units and processes for effluent treatment is very much necessary.

In the present study an effort has been made to evaluate one of the ETP provided for the treatment of wastewater generated by dairy industry. The study was limited to the performance evaluation of the ETP Plant of dairy industry.

Characterization of wastewater from different units of processing plant and management strategies are not studied.

Objective and Scope

The main objective of performance evaluation is to check that the effluent generated from the dairy is getting properly treated or not in ETP.

1. To monitor performance of the ETP

2. To address wastewater compliance issues related to gardening purpose.

The study included

1. Characterization of wastewater to the ETP

2. COD, BOD, Nutrient and TSS.

|

Figure 1: Dairy Processes Click here to view figure |

Methodology

Wastewater from dairy industry and their treatment

Operation of Dairy Industry and Effluent Generation

The dairy industry involves processing raw milk into the products such as consumer milk, butter, cheese, condensed milk and milk powder using processes such as pasteurization, packeting filling in cans etc. The milk industry is one of the most widely spread of all the industries. These vary from small receiving stations to large plants where most of the products made from milk are manufactured4. Composite flow diagram showing the major operations for the processing of the more common milk products. Dairies are centers where raw milk is processed, either for immediate consumption or converted into dairy products such as whey, cheese butter etc.

Dairies handling milk are classified as receiving, packeting, condensing, cheese making and butter making.

|

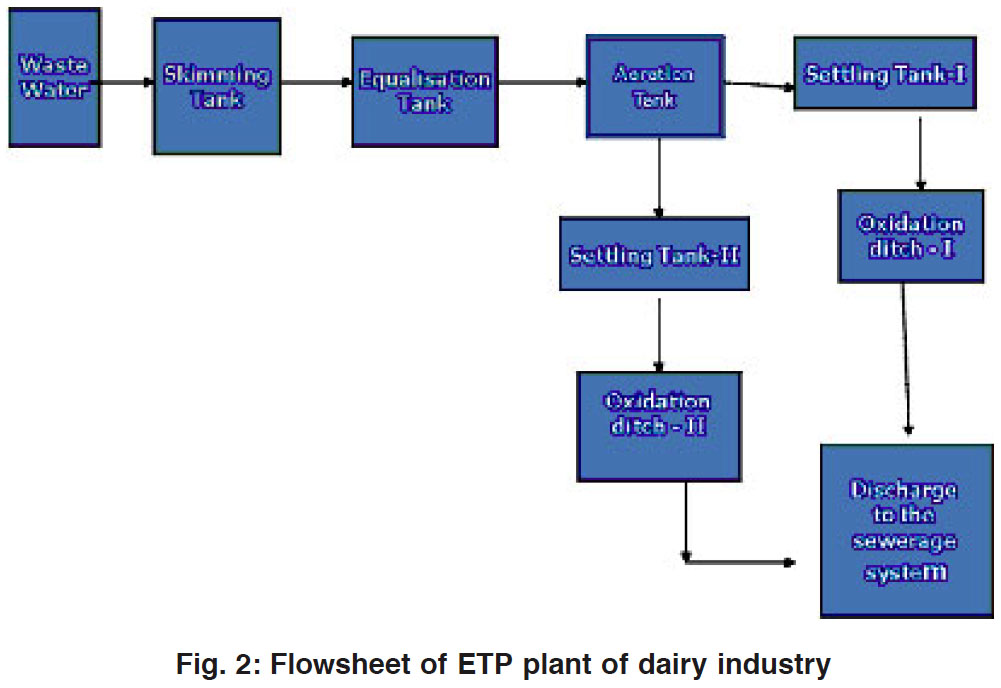

Figure 2: Flowsheet of ETP plant of dairy industry Click here to view figure |

|

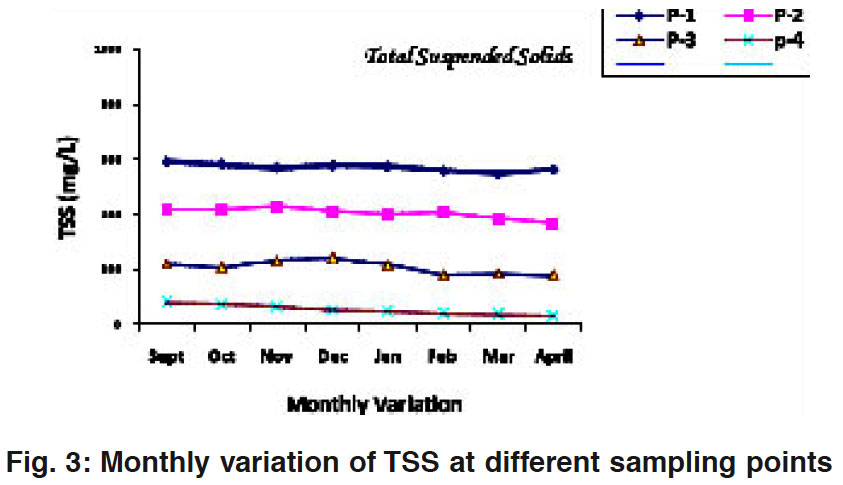

Figure 3: Monthly variation of TSS at different sampling points Click here to view figure |

|

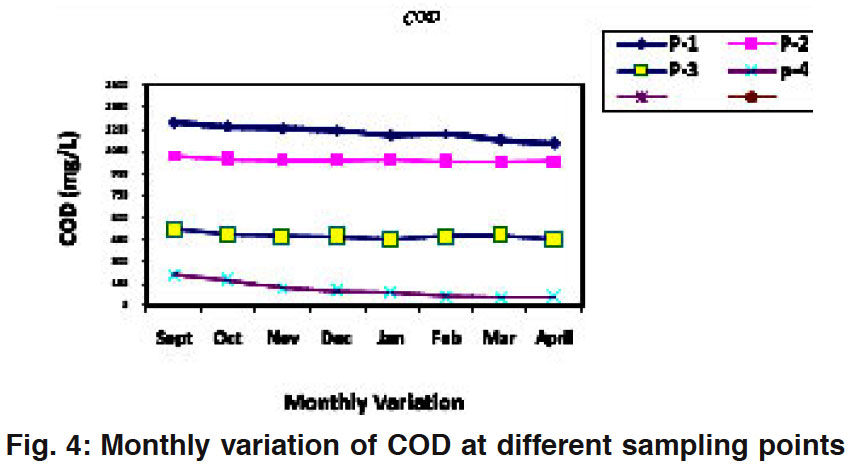

Figure 4: Monthly variation of COD at different sampling points Click here to view figure |

Operation in a Dairy

i. Receiving

ii. Pasteurization

iii. Packeting

iv. Butter making

Waste Water and their Sources

Wastes from milk product manufacture contain milk solids due to varying concentration and in dilute condition5. These solids enter the waste from almost all of the operations. In general, the wastes generated from dairy industry are as follows-

1. The washing and cleaning out of product\ remaining in the tank, trucks, cans, piping, tanks and other equipment is performed routinely after every processing cycle.

2. Spillage is produced by leaks, overflow, freezing-on, boiling over and careless handling.

3. Processing losses include:

* Sludge discharge from settling tank

* Discharges from bottles and washers

* Splashing and container breakage in automatic packaging equipment

4. Detergents and other compounds are used in the washing and sanitizing solution that are discharged as a waste.

5. Spoiled products, by-products such as whey wasted.

Effluent Treatment Plant

The Effluent Treatment Plant of Government Milk Scheme of Dairy Industry, Distt. Nagpur having capacity to treat 150 m3/day of wastewater was selected for the study.

The system was designed to handle to treat waste water having high organic content and suspended solids10.

|

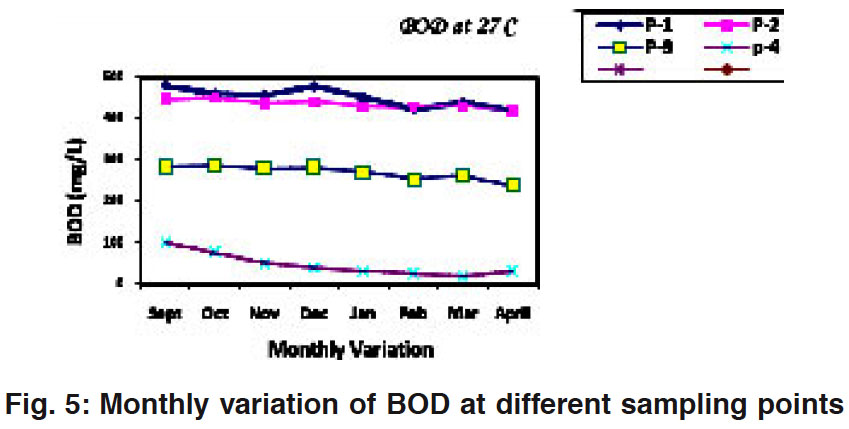

Figure 5: Monthly variation of BOD at different sampling points Click here to view figure |

|

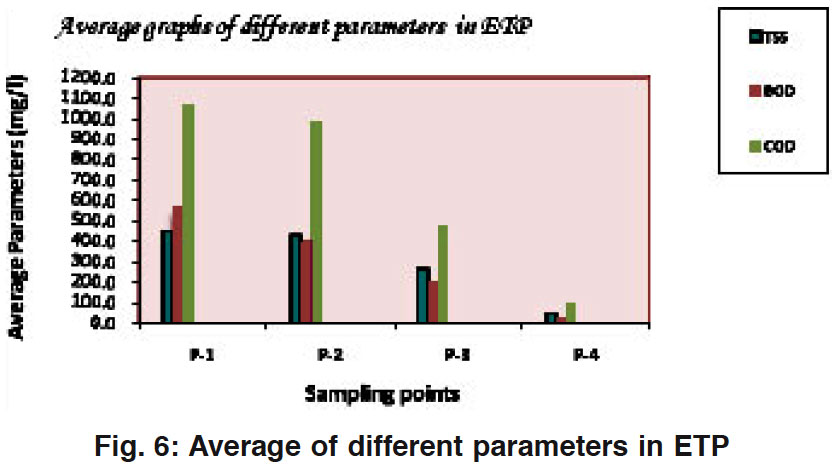

Figure 6: Average of different parameters in ETP Click here to view figure |

Treatment Units in ETP

1. Skimming Tank

2. Equalization Tank

3. Aeration Tank

4. Settling Tank

5. Oxidation Tank The systematic flow diagram of ETP is shown in Figure.

The major pollutants in wastewater discharges from dairy industry are organic matter, suspended solids, pH and fats. In this plant, The system was designed to handle BOD at 27° C of 30mg/L and Total suspended solids (TSS) 150mg / L. The various point sources of wastewater is collected in a combined underground sewer and conveyed to the effluent sump, equalization takes place, then feed the wastewater into the subsequent units. The effluent passes through the oil and grease separator i.e. skimming tank, after that flow is divided into two parts and passes through the aeration tank. The combined effluent from the aeration tanks the passes through Oxidation ditch. The treated effluent from the oxidation ditch is discharged to the sewerage system or it is used for gardening purpose.6

Process in the treatment of industrial effluent may consist of any one or more of the following processes:

1. Equalization

2. Neutralization

3. Physical Treatment

4. Biological Treatment

|

Table 1: The wastewater minimization strategies are as follows Click here to view table |

|

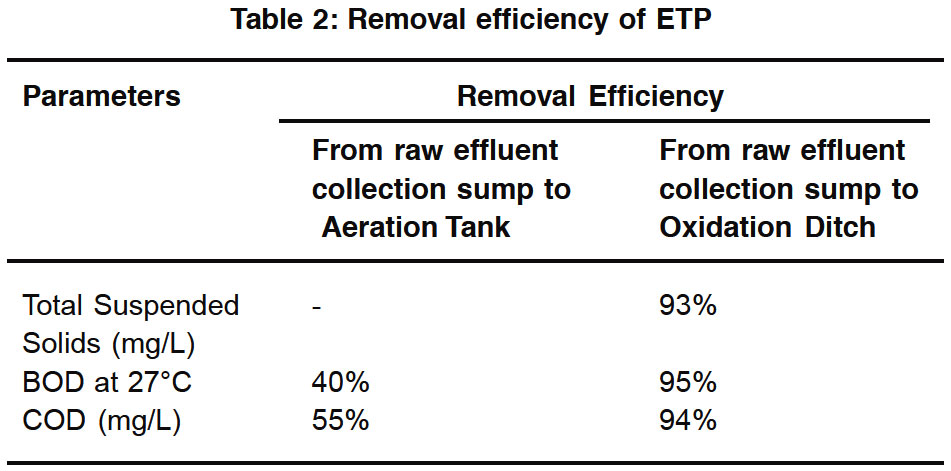

Table 2: Removal efficiency of ETP click here to view table |

Results and Discussion

Samples were collected from six points. Sampling points are waste water [P-1], Equalization Tank [P-2], Aeration Tank [P-3], and Oxidation Tank [P-4] to evaluate the performance of Effluent Treatment Plant. Results have been summarized and discussed in the following sections.7

Performance of ETP

a. Influent characteristics

b. Oxidation ditch

Secondary Effluent: Sewerage System

Data presented in figure shows monthly variation of TSS at different sampling points. Samples collected from various sampling points, reading should be vary seasonally, So, [p-1] sampling is a raw water sample that concentration is already high. That wastewater treated in [p-4] treatment unit i.e. oxidation ditch after that wastewater is discharged to the sewerage system or gardening purpose. Suspended solids in a wastewater removed upto 32 mg/L.

Data presented in Fig. 4.2 shows the monthly variation of COD at different sampling points. COD in the raw effluent was found to be 1243 mg/L, which is reduced to 60 mg/L after secondary treatment.

Data presented in figure shows monthly variation of BOD at different sampling points. BOD in raw effluent was found to be 480mg/L which is reduced to 30mg/L after secondary treatment. BOD is highly reduced after secondary treatment The performance of ETP in terms of average graph i.e. average reading of each treatment units and finding the removal position of each parameters after treatment process that is given in Fig. 4.4.

The performance of ETP in terms of average change (%) in the pollution parameters given in Table 19. In this table, % efficiency is given in average efficiency of aeration tank and oxidation ditch. Efficiency of units (Aeration tank and oxidation ditch) is found out in terms of percentage. The BOD/COD ratio of the industrial effluent is more than 0.6, it is biologically treatable. If the BOD/COD ratio is less than 0.3 biological treatments is not necessary. Biological treatment methods is used in this plant i.e. Oxidation Ditch. Settled sludge from the oxidation ditch is recirculated back into aeration tanks for maintaining required MLSS.8 The settled sludge is pumped / recirculated into the aeration tank by the help of recirculated pump

Conclusion

Present study concerned with the performance evaluation of ETP for dairy industry and it is used for the gardening purpose.

1. The COD, BOD and TSS removal efficiency of ETP was observed to be 94%, 95% and 93% respectively inspite of the fact that raw sewage.

2. BOD: COD ratio was 0.5.

3. It was observed that the plant working condition is satisfactory.

4. But somewhere, reading is continuously vary day by day or season by season; either it is high or low due to overflow rate.

5. Plant performance is good. The wastewater of that plant is used for the gardening purpose or it will go to the sewerage system. They are not reused.

References

1. APHA, AWWA and WPCF,”Standard method for the examination of water and wastewater”. 19th edition, jointly edited by Eaton, A. D.Clesceri, L.S. and Greenberg, A. E (1995).

2. Panesar P.S., Rai R., Marwaha S.S. Biological treatment of dairy industry effluents. Asian J. Microbial Biotechnology Env. Sci. 1(1-2): 67-72.

3. Harper, W.J.(1974),”Implant control of dairy wastes”. Food Tech.28, 50.

4. “Environmental Guidelines for the Dairy Processing Industry

5. V.Yip,S.D.Amsfield and A.W.Hydamaka, J.Dairy Sci.79: 710-716 (1996).

6. Baisali Sarkar, P.P. Chakrabarti, A. Vijaykumar, Vijay Kale., Wastewater treatment in dairy industries-possibility of reuse (2005).

7. Carawan, R.E., V. A. Jones and A.P.Hansen.1972. Water and wastewater management in dairy processing. UNC WWRI No.79, North Carolina state univ., Raleigh.

8. P.M. Ndegwa, L. Wang, and V.K. Vaddella. Stabilization of dairy wastewater using limited aeration treatments in batch reactors. Biological Systems Engineering Department, Washington State.

9. Federal water pollution control act Amendments of 1972.public law 92-500.

10. American Public Health Association, American Water Works Association and Water pollution control federation. Standard methods for examination of waste and wastewater. 13th ed. APHA, Washington, DC. 974 (1971).