Modification and Performance of a Rotating Biological Contactor for the Rectification of Synthetic Auramine O dye Wastewater

1

Department of Environmental Engineering,

Government Engineering College,

Valsad,

Gujarat

India

2

Gujarat Technological University,

Ahmedabad,

Gujarat

India

3

Department of Chemical Engineering,

G H Patel College of Engineering and Technology,

Vallabh Vidyanagar,

Gujarat

India

Corresponding author Email: drkaushiknath2013@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.18.3.15

Copy the following to cite this article:

Modi K. K, Nath K. K. Modification and Performance of a Rotating Biological Contactor for the Rectification of Synthetic Auramine O dye Wastewater. Curr World Environ 2023;18(3). DOI:http://dx.doi.org/10.12944/CWE.18.3.15

Copy the following to cite this URL:

Modi K. K, Nath K. K. Modification and Performance of a Rotating Biological Contactor for the Rectification of Synthetic Auramine O dye Wastewater. Curr World Environ 2023;18(3).

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2023-05-20 |

|---|---|

| Accepted: | 2023-10-16 |

| Reviewed by: |

Eman H. Khader

Eman H. Khader

|

| Second Review by: |

Aparna Gunjal

Aparna Gunjal

|

| Final Approval by: | Dr. Hiren B. Soni |

Introduction

The disposal of domestic and industrial wastewater into the drainage/atmosphere without treatment is a major source of pollution that endangers the health of the population and needs to be controlled. The prime traditional technologies for the domestic/industrial wastewater treatment such as tertiary nutrient removal and activated sludge are expensive for the treatment of wastewater to provide a satisfactory solution. The attached growth technology relies on the principle that organic matter present in the wastewater is removed by microorganisms1. The major benefits of the attached growth technology compared to the activated sludge process are – the simplicity in operation and design, less requirement of land area, short time for start-up, less energy requirement, no bulking problems, ease in operation, better recovery from shock loading, and less maintenance2.

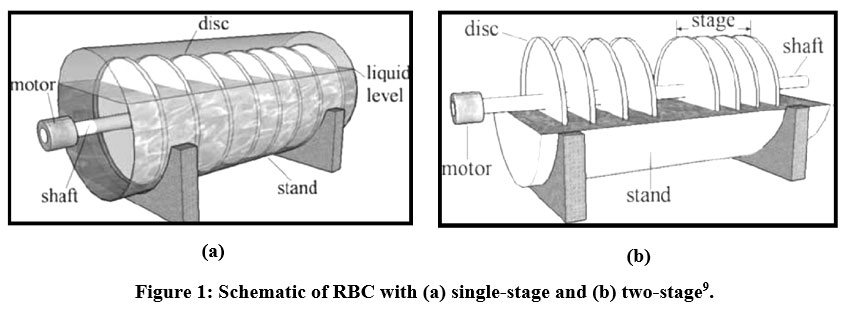

A rotating biological contactor (RBC) is a bioreactor based on an attached growth technology that provides a promising substitute of the traditional activated sludge process for the secondary treatment of industrial and domestic wastewater. The use of RBC(attached growth secondary treatment process) is the biological treatment process of wastewater that mainly relies upon the growth of microbes/bacteria and provides a high level of removal of biodegradable organic pollutants to improve the quality of wastewater for disposal, which cannot be achieved with the use of clarification process alone. The conventional RBC is composed of a series of numbers of corrugated or flat closely spaced discs mounted on a single horizontal shaft and partially or completely submerged in wastewater3,4. The entire assembly is placed in a wastewater tank with the shaft of RBC remaining above the wastewater surface so that nearly half a portion of the series of discs remains immersed in wastewater. The shaft and discs are rotated by an electric motor connected to gearboxes or belt and pulley systems, to bring them into contact with the wastewater. The biofilm (growth of the microorganism) is developed on the surface of the discs, and the rotation of the shaft brings it into contact with the wastewater, facilitating the organic matter present in the wastewater to be digested5,6.Figure 1 presents a schematic diagram of single-stage and two-stage conventional RBC.

| Figure 1: Schematic of RBC with (a) single-stage and (b) two-stage9.

|

Cortez et al.4 have reviewed the influence of various operating parameters such as retention time, organic loading rates (OLRs), rotational speed, hydraulic loading rates (HLRs), dissolved oxygen (DO) levels, etc. on the performance of RBC.Pariente7 developed a lab-scale model of a five-disc RBC for the biological treatment of pre-treated wastewater using heterogeneous catalytic wet hydrogen peroxide oxidation and achieved total organic carbon and total nitrogen (TN) reduction of 78% and 50%. Ebrahimi et al.8integrated the RBC for the anaerobic conditions with the moving-bed biofilm reactor (MBBR) as the combined aerobic process. With the additional benefit of methane production, the integrated system achieved a removal efficiency of 98% from influent having a chemical oxygen demand (COD) of 10g/L. Johnson et al.9 developed a novel pilot-scale system comprised of multiple algae wheel rotating algal contactors to treat the high strength municipal anaerobic digester filtrate. At HRTs of 0.5 to 2 days, the removal of total ammonia nitrogen by anabolic uptake variation and microbial oxidation was obtained in the range of45%-60%.Wang et al.10 evaluated the performance of non-woven fifteen-disc RBC for the treatment of municipal sewage and achieved COD and TN removal rates of 83.12% and 79.13%. Choolaka11 proposed the rotational sponge reactor for sewage treatment and achieved nitrification, COD removal, and nitrogen removal efficiencies of 97%, 91%, and 65%, respectively. Talwar et al.12 utilized a combination of photocatalytic degradation and single-stage rotating bio-disc RBC for the biological treatment of pharmaceutical wastewater and obtained an overall degradation efficiency of 96.5%.

Tawfik et al.13 have developed the series connection of a two stage RBC system to treat municipal wastewater at temperatures ranging from 12 to 24°C. The experiments were conducted at different OLRs and hydraulic retention times (HRTs) for the optimization of RBC performance. The overall COD removal efficiency significantly reduces with the reduction in total HRT(in the range of 10 to 24 h) and an increment in OLR (in the range of11 to 47g/m2/d).The removal of the major part of COD occurred in the first stage whereas nitrification occurred in the second stage and the quality of effluent of soluble COD remained unaffected. Chen et al.14used a three-stage net-like RBC (nine discs in each stage) to treat the municipal synthetic wastewater and achieved a COD removal rate of 80–95% when organic loading varied between 16 and 40 g?COD/m2?d.Vasiliadou et al.15 developed the bench-scale model of a two-stage conventional RBC (five discs in each stage) for the biological removal of pharmaceutical compounds. Various experiments were carried out to investigate the influence of pharmaceutical concentration, substrates loading and volumetric flow rate on the performance of RBC. The maximum pharmaceutical compound removal of nearly 85% was achieved for all pharmaceuticals. Su et al.16evaluated the efficacy of a three stage RBC with rotating bio-discs (twelve discs in each stage) to treat the high-strength antibiotic pharmaceutical residual liquid mingled with ordinary wastewater. A 45% COD and 40% NH4+ -N removal efficiency was achieved. Ebrahimi et al. 17 developed a bench-scale three-stage RBC, comprised of three equal-sized compartments separated by fixed baffle plates, to remove Latvia matters and organic LV-1586 Riga from cheese whey. The maximum COD removal efficiency of 90 and 92.4% was achieved at HRTs of 24 and 36 h with OLR of 50 g?COD L/d.

The major bottleneck of the conventional RBC is the limited surface area for the growth of the biofilm because of the use of a bank of discs. The use of a bank of discs in conventional RBC has a lesser mixing effect and a less oxygenation capacity, contributing to lower mass transfer efficiency18. The largest size of commercially available high-density polyethylene (HDPE) or polycarbonate sheets sets a limit on the fabrication of single-piece discs19. Therefore, evolvement in conventional RBC has been carried out from the original design of several rotating discs to enhance efficacy. Various modifications such as the provision of corrugations on flat discs, the use of cellular meshes, etc. to provide the additional surface area per unit volume to improve the performance of conventional RBC. Corrugations increase the available surface area, improve mass transfer and enhance structural stability. At the laboratory scale, several modifications in the media of traditional RBCs have been investigated with promising outcomes concerning the removal of the substrate. To increase the biofilm area and volume, the RBC discs were modified by affixing the porous netlon sheets. A randomly packed media has been effectively utilized as an alternative for discs at the pilot and laboratory scale. Randomly packed media increases the area for the attachment of biofilm within the same size of the RBC reactor as well as enhances the turbulence, resulting in higher mass transfer efficiency. Aside from that, the cost of fabrication is nearly three times lesser than the fabrication cost of discs and the energy consumption is also lesser4,5.

Li et al.20utilized the rotating drum filled with lightweight packing media in place of the bank of discs to improve the performance of conventional RBC. The use of packing media in the drum enhances the surface area for the growth of biofilm. The NH4+ -N and TN removal efficiency of 94.1% and 80.9% were obtained with the modification. Gulhane and Ashwin21 modified the conventional RBC by replacing the bank of discs with a rotating drum filled with plastic scrubbers to increase the surface area for biofilm growth. Two baffles with perforations filled with media were used in the rotating drum to increase the area for the growth of biofilm. A reduction of 69% and 67% in biochemical oxygen demand (BOD) and COD was obtained at 3 rpm of rotation in 24 h for the modified system.

From the literature, the authors have observed that various researchers have carried out experimentations on single-stage and multi-stage conventional RBCs for the treatment of wastewater. Very few research work was observed on the rotating drum RBCs for the treatment of wastewater. The prime aim of the present study is to improve the performance of the conventional RBC by enhancing the surface area for the growth of the biofilm. To achieve the aim, the bank of discs in conventional RBC was replaced with the rotating drum in modified RBC that increases the surface area for the growth of biofilm. A laboratory-scale model of modified RBC was fabricated and a pretreated synthetic solution of Auramine-O dye as wastewater was used for the treatment in the experimental work. A comparison of the theoretical performance between the conventional and modified RBC was also carried out. The study sought to provide new insights into the treatment of wastewater of the dyestuff and textile industry and to supplement the information on clean technology.

Material and Methods

Chemicals and reagents

Commercial grade Auramine-O dye, used in the present investigation, was supplied by M/s Ravi Raj chemicals limited, Ankleshwar, Gujarat, India. The Auramine-O dye has molecular formula C17H22ClN3, molecular weight 303.37 g/mol and its aqueous solution exhibits maximum absorption at a wavelength of 485 nm. All other chemicals used in this study were of analytical reagent (AR) grade, supplied by Merck, India, and were used without further purification. Soybean Casein Digest (SCD) Broth, Xylose lysine Deoxycholate agar, Macconkey agar, Baired Parker Agar, Wison and Blairs BBS agar, Pseudomonas Agar, and urea broth used in the microbial analysis of sludge were procured from Hi Media laboratory.

Synthetic influent/effluent

In this study, the pretreated synthetic solution of Auramine-O dye wastewater was used as an influent. After the pretreatment, the pH of the synthetic solution was adjusted to 7 and COD was estimated to be 450 mg/m3. The industrial aerobic secondary recycle sludge, with mixed liquor suspended solids (MLSS) concentration of 50,276 mg/L was used as biomass for the nutrient. In the experimental work, 1 L of industrial aerobic secondary recycle sludge was diluted in 7 L of distilled water. The resulting 8 L biomass, having an initial MLSS concentration of 3106 mg/L, was seeded into the modified RBC for the development of biofilm. For the growth of microbes, 1 g/L of jaggery was added to the wastewater in the reactor22,23.

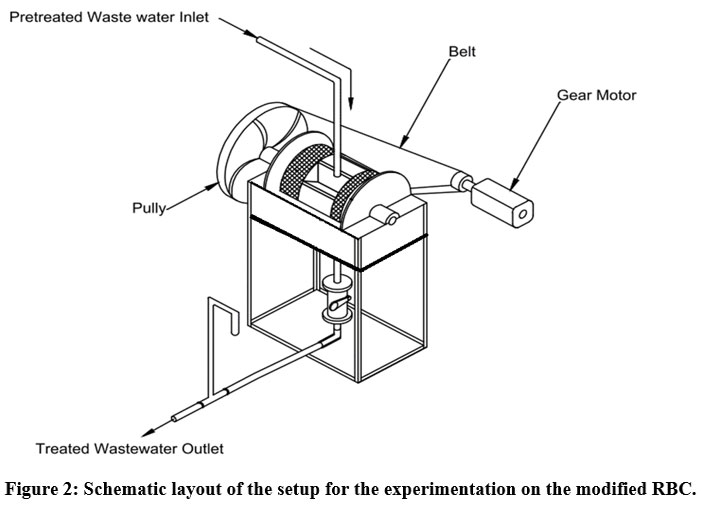

Experimental setup and working

The schematic layout of the experimental setup of the modified RBC has been presented in Figure 2. In the modified RBC, the bank of discs was replaced by the rotating drum, which was fabricated using high-density polyethylene (HDPE) and divided into three sections. The middle section of the drum had six stationary paddles, and scrubber media on both sides of each paddle was attached20. The two end sections of the drum were filled with pall rings (also called packing media) covered with porous media (also called covering net) 19,24. The use of a rotating drum in modified RBC enhanced the biofilm attachment surface area up to 2.29 m2 (?108.2% higher than conventional RBC), which enhances the performance of modified RBC. For the collection of pretreated synthetic solution/wastewater in the experimental work, the wastewater tank of 10 L capacity was fabricated using HDPE. A provision for supplying pretreated synthetic solution/wastewater (Auramine-O dye) was made at the upper part of the collection tank. A ball valve was provided in the middle, at the bottom of the collection tank, for sample collection of treated solution. The rotating drum was mounted on a horizontal shaft, which was placed longitudinally at the center of the wastewater collection tank in such a way that the rotating drum remains 40% submerged in the wastewater collection tank. The drum was rotated at 3 rpm continuously with the use of a gear motor using the belt and pulley arrangement, known as a drive mechanism. As a result of the continuous rotation of the drum, the submerged lower portion of the drum remains in contact with nutrients present in wastewater for an instant that portion of the drum comes in contact with the aerobic atmospheric condition at the second instant, resulting in the formation/growth of a microbial film on the media placed in the drum. The organic compounds present in the wastewater act as nutrients for the growth of the microbial population, resulting in the growth of the biofilm, which leads to the treatment of wastewater. To prevent the DO as a limiting factor, four small aerators were placed as a supplement aeration system in the wastewater collection tank of modified RBC. To prevent the influence of atmospheric temperature on the biological process, the blast-proof aquarium glass heater was placed in the wastewater collection tank of modified RBC. Table 1 presents the dimension of the laboratory scale model of modified RBC14,25,26.

Table 1: Dimensions of the laboratory scale model of modified RBC

| Details of reactor parameters | Dimensions |

| Volume of tank | 10 L |

| Length of drum | 35 cm |

| Number of sections | 3 |

| Partition disc diameter | 20.5 cm |

| Thickness of partition disc | 1 cm |

| Length of each section | 11.7 cm |

| Number of paddles | 6 |

| Area ofall the paddles | 756 cm2 |

| Number of pall rings | 60 |

| Drum rotation speed | 3 rpm |

| Submergence of drum | 40% |

| Figure 2: Schematic layout of the setup for the experimentation on the modified RBC.

|

Experimental methodology

In the experiment, the 8 L diluted solution of industrial aerobic secondary recycle sludge was supplied to the collection tank for the development of biofilm on the biofilm attachment surface of the drum. 1 g/L jaggery was added into the diluted solution as food for the growth of microbes once in 24 h till the complete formation of biofilm on the media surface, peddles, and drum25. The drum was rotated at a speed of 3 rpm throughout the experiment. After the development of the biofilm on the drum surface, a 700 ppm pretreated synthetic solution of Auramine-O dye/wastewater was supplied into the collection tank as an effluent after adjusting pH and COD. The effluent was kept in the wastewater collection tank for 24 h14. After the synthetic solution/wastewater was treated for 24 h, roughly 100 mL of untreated wastewater (stored in the discharge line of the ball valve) was removed. Then after, the treated wastewater sample was collected for analysis from the bottom of the wastewater collection tank. Simultaneously, a freshly pretreated synthetic solution of Auramine-O dye/wastewater was supplied for treatment into the collection tank15,27,28. During the treatment of wastewater, the reduction in biofilm or formation of dead microbes was observed and the process of treatment of wastewater was continued till the cessation of microbes (for 21 days after the development of biofilm on day-17)26.

Results and Discussion

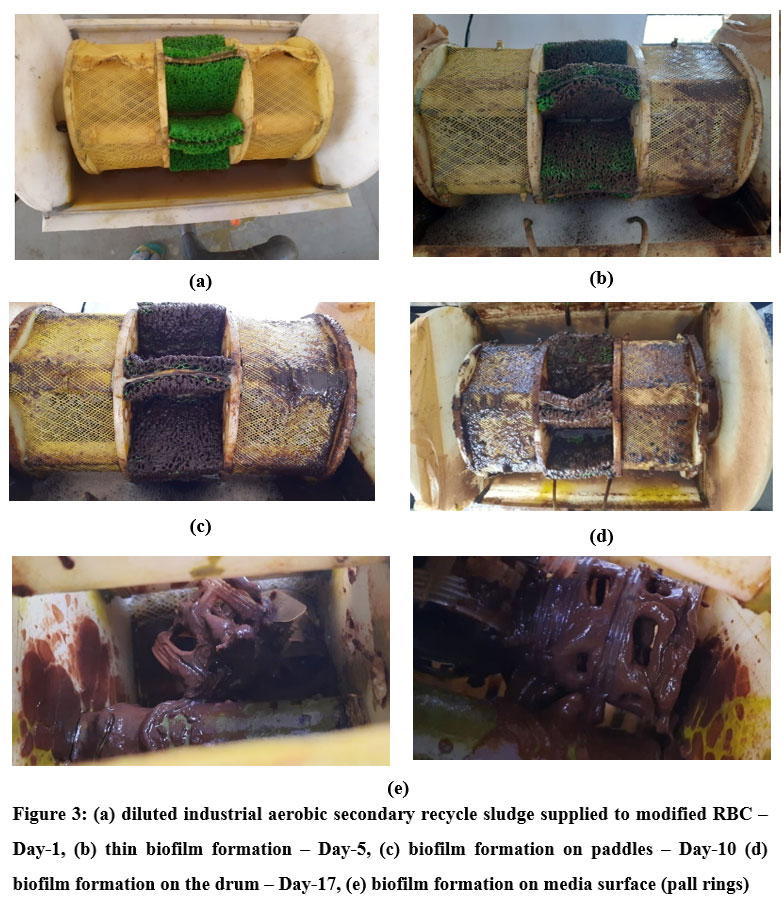

The RBC is an effective attached growth system to treat a variety of wastewater.A congregation of microbial cells enclosed in a matrix associated with the surface is known as a biofilm. The development of biofilm is an essential requirement of RBC. A biofilm, living biomass, attached to the discs/packing media/covering net/paddles/scrubber media assimilates the nutrients and organic pollutants in the wastewater. In the present study, uninterrupted experiments on RBC were carried out for a period of 17 days. On day-1, the 8 L diluted solution of industrial aerobic secondary recycle sludge along with 1 g/L jaggery was supplied in the collection tank 22,23. The photographic view of the experimental setup for day-1 is presented in Figure 3(a). The commencement of the formation of the thin microbial film on the media surface and the rotating drum was observed on day-5, as shown in Figure 3(b). Typically, the colour of the developed biomass on the media was observed as tan-brown. After day-10, the formation of moderately thick biofilm on the paddle surface and the drum was observed as shown in Figure 3(c). Figure 3(d) depicts the biofilm development on the drum and paddles after day-17, whereas Figure 3(e) shows the formation of biofilm on the pall rings used in the modified RBC29. The normal healthy growth of biofilm/microbes was observed dense on the major portion of the media surface, drum, and pall ring because of the availability of healthy food in the form of jaggary/BOD. The formation of biofilm can be observed visually as well as through microscopic examination of media.

| Figure 3: (a) diluted industrial aerobic secondary recycle sludge supplied to modified RBC – Day-1, (b) thin biofilm formation – Day-5, (c) biofilm formation on paddles – Day-10 (d) biofilm formation on the drum – Day-17,(e) biofilm formation on media surface (pall rings)

|

After the visible and dense formation of biofilm or growth of bacteria (on day-17), a pretreated synthetic solution of Auramine-O dye/wastewater (initial BOD of 123 mg/L) was supplied into the wastewater collection tank of modified RBC for the treatment. Before the continuous testing phase is carried out, the growth of biofilm/active sludge has the ability to demean the organic compounds contained in the wastewater. Therefore, when wastewater is supplied, the microorganisms do not require a relatively long time to degrade the wastewater, and the process is known as acclimatization. After each day of treatment, the treated wastewater remedy was collected for analysis (on each day of the experiment).As per the methodology describe, three sets of experiments were conducted on the modified RBC. However, the result of average of observations of three sets was presented and described with the standard deviation (SD) in this section.

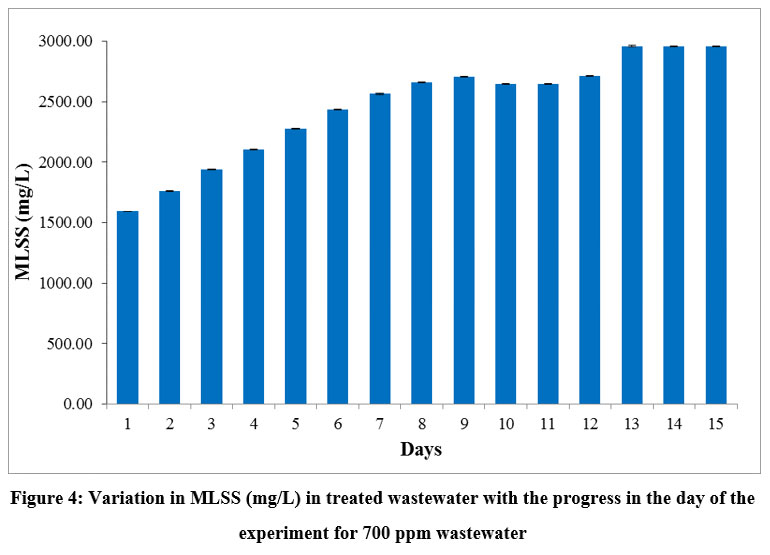

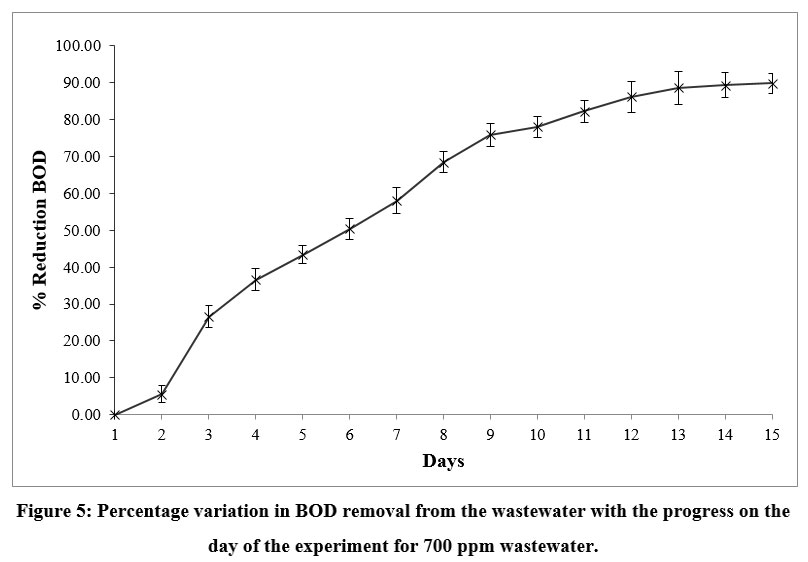

Figure 4 depicts the variations in the MLSS (mg/L) in the treated wastewater solution with the progress of the days of the experiment. Figure 5 presents the percentage variation in BOD removal efficiency with the progress of the days of the experiment. The initial MLSS concentration of 8 L diluted industrial aerobic secondary recycle sludge was estimated to be 3106 mg/L before acclimatization which was reduced to 1593 mg/L (SD = 5.13) at the end of day-17 of the growth of biofilm. When the pretreated synthetic wastewater of Auramine-O dye was fed into the modified RBC on the day-18 (the 1st day of the treatment for pre-treated synthetic wastewater), the concentrations of MLSS and BOD were found to be 1593 (SD = 5.13) mg/L and 125.87 mg/L (SD = 4.97) respectively. MLSS concentration remained at 1593 (SD = 5.13) mg/L at the end of the treatment of wastewater on Day-1, as the microbes/biomass getting acclimatized to the new environment on Day-1 of the experiment. MLSS represents the presence of the active biomass available for consumption of organic pollutants present in wastewater. The concentration of BOD decreased over time in wastewater present in the wastewater tank of modified RBC as the microorganisms consumed the biodegradable organic compounds present in wastewater for growth and reproduction in the presence of oxygen, resulting in an increase in cell mass MLSS concentration. In other words, the more the consumption by biomass the lower will be the BOD in the discharge. After day-5, the MLSS concentration increased to 2275 mg/L (SD = 6.11), while the BOD concentration reduced to 71.23 mg/L (SD = 5.08), indicating a 43.44% reduction in BOD. After day-7, the MLSS concentration rose to 2564 mg/L (SD = 6.11), and the BOD concentration reduced to 52.93 mg/L (SD = 6.68), resulting in a reduction of 58.04% (SD = 3.57) in BOD. After day-10, the MLSS concentration increased to 2644 mg/L (SD = 4.58), and the BOD concentration reduced to 27.77 mg/L, resulting in a reduction of 78.01% (SD = 2.80) in BOD. After day-15, the MLSS concentration increased to 2960 mg/L (SD = 4.93), and the BOD concentration reduced to 12.85 mg/L (SD = 4.03), resulting in a reduction of 89.86% (SD = 3.35) in BOD, indicating the meeting of effluent discharge standards .A constant level of percentage variation in BOD removal efficiency was observed after 15 days of the experiment. In the present study, an 89.86% BOD removal efficiency was obtained from the wastewater. With the progress on the day of the experiment, an increment in the MLSS value of treated wastewater was observed, which indicates the decrement in the digestive capacity of microbes. The amount of wastewater treated relies on the area of the media surface for the biofilm formation and the quality and volume of supplied wastewater.

Under the operating conditions of the experiment, the modified laboratory-scale RBC proved to be a very efficient system for establishing a biofilm. At the beginning of the operation, experimental conditions were adequate for the induction phase of biofilm formation-organic absorption followed by the transport and subsequent attachment of microorganisms to the surface. The increased biofilm thickness without an increment in the treatment efficiency of the modified RBC can be explained by the removal rate of the substrate. This further relies on the biofilm's active outer layer and the active layer depth, which is regulated by the DO diffusivity into the biofilm27. Few biofilms are detached from the drum and are re-established onto the drum surface, resulting in relatively stable biofilm thickness for the treatments, as shown in Figure 3.Polyvinylchloride is a good material for supporting the effective growth of a mixed population biofilm. Samples of the biofilm were mounted on a microscope slide.

| Figure 4: Variation in MLSS (mg/L) in treated wastewater with the progress in the day of the experiment for 700 ppm wastewater.

|

| Figure 5: Percentage variation in BOD removal from the wastewater with the progress on the day of the experiment for 700 ppm wastewater.

|

A summary of important features of various RBCs, both as a stand-alone and in combination with other reactor configurations, using a state-of-art of literature is presented in Table 3. Reactor volume, configuration, the material of construction, solid matrix media, total surface area, percentage of submergence, speed of rotation (RPM), and HRT have been compared with similar types of systems. The longer HRT in RBC could enhance substrate diffusion into the biofilm it might not be always economically favorable, and too short an HRT could result in lower removal rates. Even though, HRT of 1 day was chosen in the present study, a significant removal rate in BOD was obtained due to the modification in RBC. In the bench and laboratory scale RBC, the use of a packing matrix increases the area for biofilm attachment and increases the turbulence, resulting in higher mass transfer efficiency. Various types of packing such as plastic scrubbers, polyurethane foams, wood charcoal, netlike rubbery materials, saddles, and many others with different sizes were used in randomly packed RBC systems (Table 3).Their careful selection is based on ease of availability, cost, and appropriate orientation to facilitate the growth of biofilm. The RBC’s rotational speed has considerable influence on oxygen and nutrient transfer rate to the biofilm and removal of contamination. Various investigations on the influence of rotational speed on the performance of RBC are summarized in Table 3.Typically, an increased speed of rotation results in the increase of concentration of DO available for the microorganism but higher rotational speed incurs higher power consumption thereby increasing the cost of operation. Furthermore, there are chances of tearing and stripping of microorganisms off the media in case of too high rotational speed. This might lead to lowering the biodegradation rate and deterioration of effluent quality in the reactor. The percentage submergence of the RBC medium is an important influencing parameter for its efficient operation. Percent submergence for the present study was 40% which is almost the same for various other reported works (Table 3). Percent submergence relies on several factors, such as characteristics of the effluent to be treated, microorganisms, and type of operation whether batch or continuous. Submergence is typically around 40% in aerobic processes of municipal wastewater treatment, but it can reach 60% in nutrient removal. However, there is no reference value for the submergence of disc due to the wide variation in the characteristics of wastewater. Submergence of more than 50% might result in a decreased oxygen transfer rate.

Table 2: Comparative summary of RBC

| Capacity (L), Type of RBC, Material of construction | Media used | Type of wastewater | Total surface Area (m2) | Submergence (%) | Rotational Speed (rpm) | HRT (days) | Major Findings | References |

5.25, RBC integrated with advanced oxidation, AISI 304 Stainless steel (SS) | ---- | Agrochemical wastewater | 0.71 | 40 | 30 | 25 | 78% TOC removal and 50% TN removal | 7 |

24.5, [two-stage] [bench-scale]:10, SS | ---- | Pharmaceutical wastewater | 1.41 | 40 | 20 | 5.7-10 | 85% removal of pharmaceutical compounds | 15 |

60, [drum in place of disc] lab scale-single stage continuous mode, Galvanized iron (GI) Sheet | Plastic scrubber | Domestic wastewater | ---- | 40 | 3,5,7 | 1-1.3 | BOD - 69% and COD -67% removal | 28 |

10, [Four compartments] RBC coupled with catalytic fixed bed reactor, SS | ---- | Industrial agro- chemical wastewater | 1.44 | 40 | ---- | ---- | Useful as a cost-effective process. | 30

|

60, 0.5 mm thick GI sheet | Case A: Snail shell; case B: plastic scrubber case C: wood charcoal | Synthetic wastewater | ---- | 40 | 3 | 1 | Case A: 69.29% BOD, 68.90% COD, and 72.66% total solid removal Case B: 71.32% BOD,71.11% COD, and 73.95% TS Removal Case C: 70.51% BOD, 71.55% COD, and 72.70% TS removal | 31 |

69, Netlike RBC, three-stage, SS

| Net like structure rubber material | Municipal type synthetic wastewater | 1.27 | 45 | variable | 0.4 | 80%-95% COD, 40.2%-61.4% TN, low sludge | 14 |

46.5, Anaerobic RBC batch mode, [combined Moving-Bed Biofilm Reactor +RBC], SS | Polyurethane foam | Synthetic wastewater high strength organic wastewater | 0.393 | 100 | 5-10 | 1- 4 | 98% COD removal | 8 |

793, pilot scale [rotating algal contactors], HDPE | Pin-type ball surface area | High strength municipal wastewater | 5 | ---- | ---- | 0.5 to 2 | 80% less electricity required, Removal of total ammonia nitrogenby anabolic uptake and microbial oxidation = 45 % and 60% respectively. | 9

|

78.75, [batch scale, three-stage], SS | Thin blades of polyvinyle chloride | High-strength wastewater from cheese whey effluent | 7.79 | 33 | 4 | 1.5 | 90% removal of COD at 24 h HRT and 92.4% removal of COD at 36 h | 17 |

50, Semi-pilot scale (photocatalytic rotating reactor), [RBC + Modified catalyst TiO2/Ag], SS | TiO2 doped with Silver | Industrial wastewater | 387 | 40 | 54 | 2.08 | Decrease in HRT increased the degradation efficiency. | 32 |

2.5, [Non-woven RBC], SS | Porous polyester coated with Pyradinium type polymer | Municipal sewage with low carbon to nitrogen | ---- | ---- | 2 | 0.2 | 83.12% COD and 79.13% TN removal | 10 |

90, [diameter - 2.4 m, width - 0.5 m ] | G-3 type Polyurathan sponge | Sewage wastewater | ---- | 15 | 18 | 0.2 | 91% COD, 97% Nitrification, 65% nitrogen removal | 11 |

1, [One stage], [TiO2 photocatalysis and RBC] | lightweight plastic foam | Real Pharmaceutical wastewater | ---- | 40 | 1-1.2 | 30 | 96.5% removal by combined process (TiO2+ RBC) | 12 |

5, RBC [lab scale], SS | Acrylic pastictrans parant sheet | Synthetic Wastewater containing phenol | ---- | 40 | 5 to 50 | 0.6 to 1.45 | Phenol removal= 56% at 14 h HRT | 33 |

17.2, RBC, Plastic material | ---- | Antibiotic Pharmaceutical wastewater | ---- | 45 | 4 | ---- | 45% COD and 40% NH4-N removal, 85% BOD removal | 16 |

10, MRBC [lab scale], HDPE | Pall rings and scrubber media | Pre-treated Synthetic Auramine-O dye wastewater | 2.29 | 40 | 3 | 1 | 85.7 % BOD removal efficiency | Present study |

Microorganisms/culture analysis

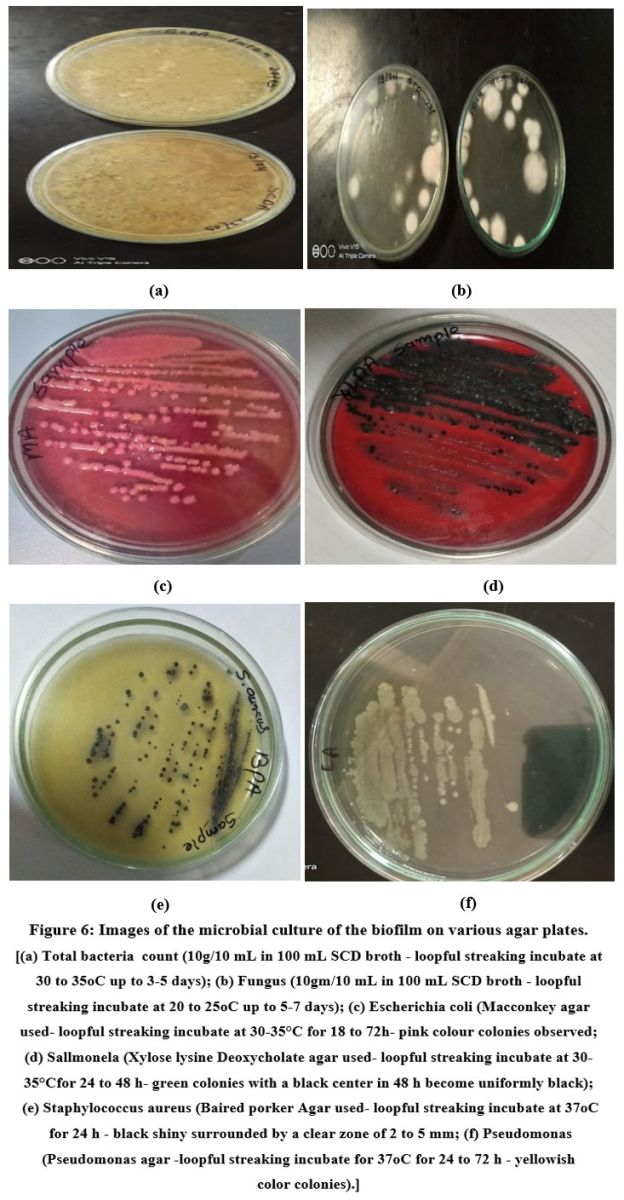

The sludge samples were collected from different parts of the drum. Spatula and sterile glass bottles were used to collect the samples. The sample of sludge was stored in the laboratory at 4 oC to prevent degradation. The analysis of the biofilm was carried out by following the standard methodologies. Microscopic observations and standard gram staining were carried out to characterize the isolates as per the standard procedure. Figure 6 presents a microscopic observation showing the higher organisms in the biofilms1.

In the test procedure, the test sample of sludge was first neutralized and incubated for 24 h. The neutralized test sample of 10 mL /10 g was incubated at 30-35 °C for 24 h in 90 mL Soybean Casein Digest (SCD) broth. To determine the total bacteria count, the incubated test sample in SCD was incubated at 30-35 oC temperature for up to 3-5 days and counting of colonies was found up to 45×10-4 cfu/gm (Figure 6(a)). For the identification of the presence of fungus, the incubated test sample in SCD was incubated at 20-25 oC for up to 5-7 days and the result indicated the presence of fungus in the sludge (Figure 6(b)). The incubated test sample in SCD was incubated at 30-35°Cin Macconkey agar medium for 18-72 h and the production of acid and gas was observed, as well as the change in pink colour indicating the presence of Escherichia coli colonies(Figure 6(c)). The incubated test sample in SCD was incubated in Xylose lysine Deoxycholate agar medium, which resulted in the green colonies with a black center that turn into uniformly black in 48 h indicating the presence of Sallmonela colonies(Figure 6(d)). The incubated test sample in SCD was incubated in Baired porker Agar medium, which resulted in the black shiny surrounded by a clear zone indicating the presence of Staphylococcus aureus (Figure 6(e)). The incubated test sample in SCD was incubated in Pseudomonas agar medium, which turns into yellowish colour colonies indicating the presence of Pseudomonas (Figure 6(f)). The laboratory test procedure to identify the presence of culture/species in the microbial film is summarized in Table 3. The laboratory results indicate the presence of mixed culture/micro-organisms in the sludge; hence it is quite difficult to identify the percentage removal of contaminants by the various kinds of bacterial colonies.

Table 3: Testing procedure of culture

Culture/ microorganisms | Quantity of sample | Medium inoculated/ streaked | Observation (after incubation) | Conclusion |

Total bacteria count | 10g/10 mL in 100 mL SCD broth | Loopful streaking incubate at 30-35 oC up to 3-5 days | Count the colonies | Count the colonies |

Fungus | 10g/10 mL in 100 mL SCD broth | Loopful streaking incubateat 20 to 25oCup to 5-7 days | Count the colonies | Count the colonies |

Escherichia coli | Macconkey agar | Loopful streaking incubate at 30-35°C for 18 to 72 h | Pink colour colonies present | Escherichia coli is confirmed |

Sallmonela | Xylose lysine deoxycholate agar | Loopful streaking incubate at 30-35°C for 24 to 48 h

| Green colonies with a black colour center, become uniformly black in 48 h | Sallmonela present |

Staphylococcus aureus | Baired parker agar | Loopful streaking incubate at 37oC for 24 h | Black shiny surrounded by a clear zone of 2 to 5 mm Present | Staphylococcus aureus present |

Pseudomonas | Pseudomonas agar for detection of fluorescent | Loopful streaking incubate at 37oC for 24 to 72 h. | Yellowish color colonies | Pseudomonas present |

| Figure 6: Images of the microbial culture of the biofilm on various agar plates.

|

[(a) Total bacteria count (10g/10 mL in 100 mL SCD broth - loopful streaking incubate at 30 to 35oC up to 3-5 days); (b) Fungus (10gm/10 mL in 100 mL SCD broth - loopful streaking incubate at 20 to 25oC up to 5-7 days); (c) Escherichia coli (Macconkey agar used- loopful streaking incubate at 30-35°C for 18 to 72h- pink colour colonies observed; (d) Sallmonela (Xylose lysine Deoxycholate agar used- loopful streaking incubate at 30-35°Cfor 24 to 48 h- green colonies with a black center in 48 h become uniformly black); (e) Staphylococcus aureus (Baired porker Agar used- loopful streaking incubate at 37oC for 24 h - black shiny surrounded by a clear zone of 2 to 5 mm; (f) Pseudomonas (Pseudomonas agar -loopful streaking incubate for 37oC for 24 to 72 h - yellowish color colonies.

Conclusion

The motive of the present research study was to improve the performance of the conventional RBC by enhancing the surface area for the growth of the biofilm. To achieve the aim, the bank of discs in conventional RBC was replaced with the rotating drum in modified RBC that increased the surface area for the growth of biofilm by nearly 108.2%. For the growth of microbes at the initial stage, 8 L diluted industrial aerobic secondary recycle sludge and 1 g/L jaggary were utilized. For the experimental work, a pretreated synthetic solution of Auramine-O dye as wastewater was utilized. A89.86% BOD removal efficiency was achieved with the use of modified RBC in the experimental work. A pretreated synthetic solution of Auramine-O dye was converted into a biodegradable solution using the modified RBC that is harmless and environment-friendly to dispose into the atmosphere. The theoretical comparison among the conventional and modified RBC indicates an enhancement of 6.7% in BOD removal efficiency. The results of experimental work indicate that modified RBC is an effective system for high organic compound wastewater the treatment and replaces the conventional RBC. The applicability of the modified RBC with conventional or packing media at a large scale can play a crucial role in the secondary treatment of wastewater. As a prospect of future scope, several modifications such as changes in rotational speed, detention time, submergence of the drum, use of recycling, and the influence of supplemental aeration can also be investigated to improve the performance of modified RBCs.

Acknowledgement

I would like to express my sincere gratitude to my beloved research supervisor Dr. Kaushik Nath, Professor and Head, Department of Chemical Engineering, G. H. Patel College of Engineering and Technology, Vallabh Vidyanagar. From the bottom of my heart, I am sincerely grateful to Dr. V. S. Purani, Principal GEC,Valsad. They gave me this Golden opportunity and permission to pursue this PhD program under Gujarat Technological University, Ahmadabad, and provided me enough facility and support to carry out the research work at my institute.

Conflict Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Funding Sources

This research has not been applied for any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

References

- Murugesan S. Performance study on Rotating Biological Contactor. 2017;(12). doi:10.13140/RG.2.2.25602.17607

- Gulhane ML, Sahare SV. Modified Rotating Biological Contactor. International Journal of Mechanical And Production Engineering. 2014;(2):2320-2092.

- Engineering B. BIOREACTORS?: ROTATING BIOLOGICAL. Published online 2013.

- Cortez S, Teixeira P, Oliveira R, Mota M. Rotating biological contactors: A review on main factors affecting performance. Reviews in Environmental Science and Biotechnology. 2008;7(2):155-172. doi:10.1007/s11157-008-9127-x

CrossRef - Kadu P a., Rao YRM. Rotating biological contactors?: A critical review. Journal of Scientific and Engineering Research. 2012;3(9):1-6.

- Morone A, Mulay P, Kamble SP. Removal of Pharmaceutical and Personal Care Products from Wastewater Using Advanced Materials. Elsevier Inc.; 2019. doi:10.1016/B978-0-12-816189-0.00008-1

CrossRef - Pariente MI, Siles JA, Molina R, Botas JA, Melero JA, Martinez F. Treatment of an agrochemical wastewater by integration of heterogeneous catalytic wet hydrogen peroxide oxidation and rotating biological contactors. Chemical Engineering Journal. 2013;226:409-415. doi:10.1016/j.cej.2013.04.081

CrossRef - Ebrahimi M, Kazemi H, Mirbagheri SA, Rockaway TD. Integrated Approach to Treatment of High-Strength Organic Wastewater by Using Anaerobic Rotating Biological Contactor. Journal of Environmental Engineering. 2018;144(2):04017102. doi:10.1061/(asce)ee.1943-7870.0001312

CrossRef - Johnson DB, Schideman LC, Canam T, Hudson RJM. Pilot-scale demonstration of efficient ammonia removal from a high-strength municipal wastewater treatment sidestream by algal-bacterial biofilms affixed to rotating contactors. Algal Research. 2018;34(December 2017):143-153. doi:10.1016/j.algal.2018.07.009

CrossRef - Wang D, Wang G, Yang F, Liu C, Kong L, Liu Y. Treatment of municipal sewage with low carbon-to-nitrogen ratio via simultaneous partial nitrification, anaerobic ammonia oxidation, and denitrification (SNAD) in a non-woven rotating biological contactor. Chemosphere. 2018;208:854-861. doi:10.1016/j.chemosphere.2018.06.061

CrossRef - Hewawasam C, Matsuura N, Takimoto Y, Hatamoto M, Yamaguchi T. Optimization of rotational speed and hydraulic retention time of a rotational sponge reactor for sewage treatment. Journal of Environmental Management. 2018;222(March):155-163. doi:10.1016/j.jenvman.2018.05.046

CrossRef - Talwar S, Sangal VK, Verma A. Feasibility of using combined TiO2 photocatalysis and RBC process for the treatment of real pharmaceutical wastewater. Journal of Photochemistry and Photobiology A: Chemistry. 2018;353:263-270. doi:10.1016/j.jphotochem.2017.11.013

CrossRef - Air W, Tawfik A, Zeeman G. Sewage Treatment in a Rotating Biological Contactor ( RBC ) System. 2006;(August). doi:10.1007/s11270-006-9138-6

CrossRef - Chen Z, Wen Q, Wang J, Li F. Simultaneous removal of carbon and nitrogen from municipal-type synthetic wastewater using net-like rotating biological contactor (NRBC). Process Biochemistry. 2006;41(12):2468-2472. doi:10.1016/j.procbio.2006.06.003

CrossRef - Vasiliadou IA, Molina R, Martínez F, Melero JA. Experimental and modeling study on removal of pharmaceutically active compounds in rotating biological contactors. Journal of Hazardous Materials. 2014;274:473-482. doi:10.1016/j.jhazmat.2014.04.034

CrossRef - Su R, Zhang G, Wang P, Li S, Ravenelle RM, Crittenden JC. Treatment of Antibiotic Pharmaceutical Wastewater Using a Rotating Biological Contactor. Journal of Chemistry. 2015;2015. doi:10.1155/2015/705275

CrossRef - Ebrahimi A, Najafpour GD, Nikzad M. Evaluation of treatability of high strength wastewater in a three stage-rotating biological contactor. Journal of Environmental Engineering and Landscape Management. 2017;25(3):234-240. doi:10.3846/16486897.2016.1223083

CrossRef - Hitdlebaugh JA, Miller RD. Operational problems with rotating biological contactors. Journal of the Water Pollution Control Federation. 1981;53(8):1283-1293.

- Ibrahim HT, Qiang H, Al-Rekabi WS, Qiqi Y. Improvements in biofilm processes for wastewater treatment. Pakistan Journal of Nutrition. 2012;11(8):610-636. doi:10.3923/pjn.2012.708.734

CrossRef - Li N, Zeng W, Yang Y, Wang B, Li Z, Peng Y. Oxygen mass transfer and post-denitrification in a modified rotating drum biological contactor. Biochemical Engineering Journal. 2019;144:48-56. doi:10.1016/j.bej.2019.01.008

CrossRef - Gulhane M, Ashwin P. Modified rotating biological contactor fitted perforated baffles. Journal of Environmental Research And Development. 2015;9(3):1003-1005.

- Delgado N, Navarro A, Marino D, Peñuela GA, Ronco A. Removal of pharmaceuticals and personal care products from domestic wastewater using rotating biological contactors. International Journal of Environmental Science and Technology. 2019;16(1). doi:10.1007/s13762-018-1658-2

CrossRef - Tonde MR. Study of Rotating Biological Contactors ( RBCs ) for Wastewater Treatment Process. Published online 2017:621-623.

- Chen S, Sun D, Chung JS. Treatment of pesticide wastewater by moving-bed biofilm reactor combined with Fenton-coagulation pretreatment. Journal of Hazardous Materials. 2007;144(1-2):577-584. doi:10.1016/j.jhazmat.2006.10.075

CrossRef - Ravi R, Philip L, Swaminathan T. Modified rotating biological contactor for removal of dichloromethane vapours. Environmental Technology (United Kingdom). 2015;36(5):566-572. doi:10.1080/09593330.2014.953553

CrossRef - Ghalehkhondabi V, Fazlali A, Fallah B. Performance analysis of four-stage rotating biological contactor in nitrification and COD removal from petroleum refinery wastewater. Chemical Engineering and Processing - Process Intensification. 2021;159:108214. doi:10.1016/j.cep.2020.108214

CrossRef - Laopaiboon L, Phukoetphim N, Laopaiboon P. Effect of glutaraldehyde biocide on laboratory-scale rotating biological contactors and biocide efficacy. Electronic Journal of Biotechnology. 2006;9(4):1-12. doi:10.2225/vol9-issue4-fulltext-10

CrossRef - Padwekar MLGKG. Modified Biofilm Reactor System for Domestic Wastewater Treatment Government College of Engineering , Amravati , Maharashtra ( India ). 2015;3(01):1087-1090.

- Costley SC, Wallis FM. Effect of flow rate on heavy metal accumulation by rotating biological contactor (RBC) biofilms. Journal of Industrial Microbiology and Biotechnology. 2000;24(4):244-250. doi:10.1038/sj.jim.2900812

CrossRef - Vasiliadou IA, Pariente MI, Martinez F, Melero JA, Molina R. Modeling the integrated heterogeneous catalytic fixed-bed reactor and rotating biological contactor system for the treatment of poorly biodegradable industrial agrochemical wastewater. Journal of Environmental Chemical Engineering. 2016;4(2):2313-2321. doi:10.1016/j.jece.2016.04.007

CrossRef - Gulhane ML, Sangekar SP. Efficiency of Rotating Biological Contactor with Specially Designed Rotating Assemblies in the Treatment of Wastewater. 2016;3(1):359-362.

- Montalvo-Romero C, Aguilar-Ucán C, Alcocer-Dela hoz R, Ramirez-Elias M, Cordova-Quiroz V. A Semi-Pilot Photocatalytic Rotating Reactor (RFR) with Supported TiO2/Ag catalysts for water treatment. Molecules. 2018;23(1). doi:10.3390/molecules23010224

CrossRef - Rana S, Gupta N, Rana RS. Removal of Organic pollutant with the use of Rotating Biological Contactor. Materials Today: Proceedings. 2018;5(2):4218-4224. doi:10.1016/j.matpr.2017.11.685

CrossRef