Appropriation of bio-diesel blends in diesel engine

M. Vivekanandan1 , G. Sridharan2 , B. Kumaragurubaran1 , P. Gopal1 * and P. Navaneetha Krishnan1

1

School of Mechanical Engineering,

SASTRA University,

Thanjavur,

India

DOI: http://dx.doi.org/10.12944/CWE.3.2.06

Use of vegetable oils (Jatropa oil) in diesel engines results increased in engine performance to take advantage of a global trend toward alternatives to fossil fuels, this work is focused on appropriation of the performance characteristics of a single cylinder diesel engine fuelled with conventional fuel and biofuels under steady conditions. Methyl esters of jatropha oil obtained from the transesterification process was tested as biodiesel fuel blends of 10%, 20%, 30%, 40%, 50% with petroleum diesel fuel. A stationary engine was mounted on a test bench and prepared for operating in steady conditions. The results suggested that the use of the diesel blends containing non-edible oil is a potential alternative for diesel fuel. All the blends showed reasonable efficiencies. Experimental results indicated that B20 have better engine performance compared with diesel.

Copy the following to cite this article:

Vivekanandan M, Sridharan G, Kumaragurubaran B, Gopal P, Krishnan P.N. Appropriation of bio-diesel blends in diesel engine. Curr World Environ 2008;3(2):245-250 DOI:http://dx.doi.org/10.12944/CWE.3.2.06

Copy the following to cite this URL:

Vivekanandan M, Sridharan G, Kumaragurubaran B, Gopal P, Krishnan P.N. Appropriation of bio-diesel blends in diesel engine. Curr World Environ 2008;3(2):245-250. Available from: http://www.cwejournal.org?p=128/

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2008-10-18 |

|---|---|

| Accepted: | 2008-12-04 |

Introduction

The world is presently confronted with the twin crises of fossil fuel depletion and environmental degradation. Indiscriminate extraction and lavish consumption of fossil fuels have led to reduction in underground-based carbon resources. The search for alternative fuels, which promise a harmonious correlation with sustainable development, energy conservation, efficiency and environmental preservation, has become highly pronounced in present context. The fuels of bio-origin can provide a feasible solution to this world-wide petroleum crisis. Gasoline and diesel driven automobiles are the major sources of greenhouse gases emission (GHG). Scientists around the world have explored several alternative energy resources, which have the potential to quench the ever-increasing energy thirst of today’s population. Various bio fuel energy resources explored include biomass, biogas, primary alcohol, vegetable oils, biodiesel, etc.

Vegetable oils are good alternatives to fossil fuels for use in diesel engines. They are particularly attractive for agricultural applications. Since vegetable oils have properties comparable to diesel, they can be used to run compression ignition engines with little or no modifications.¹ These alternative energy resources are largely environment-friendly but they need to be evaluated on case- to-case basis for their advantages, disadvantages and specific applications. Some of these fuels can be used directly while others need to be formulated to bring the relevant properties closer to conventional fuels. Due to the recent widespread use of petroleum fuels in various sectors, this study concentrates on accessing the viability of using alternative fuels in the existing internal combustion engines without any modifications. The present energy scenario has stimulated active research interest in non-petroleum, renewable and non-polluting fuels. The world reserves of primary energy and raw materials are, obviously, limited. According to an estimate, the reserves will last for 218 years for coal, 41 years for oil, and 63 years for natural gas, under a business-as-usual scenario.

The enormous growth of world population, increased technical development and standard of living in the industrial nations has led to this intricate situation in the field of energy supply and demand. The prices of crude oil keep rising and fluctuating on a daily basis. Several studies have been conducted to improve the performance of engines fuelled by vegetable oils. Modifications like preheating the oil, use of hot surface ignition, converting the oil into its esters have been found to be effective.² The use of vegetable oils for engine fuels may seem insignificant today. But such oils may become in course of time as important as petroleum and the coal tar products of the present time. Investigations carried out on variety of vegetable oils like Karanji oil, Ricebran oil, Rape seedoil etc. and their esters have shown that the methyl ester of vegetable oils offers lower smoke and higher thermal efficiency than the pure oil itself.³ In the 1930’s&1940’s the vegetable oils where used as diesel substitutes from time to time, but usually only in emergency situations. Recently, because of increase in crude oil prices, limited sources of fossil fuels and environmental concerns, there has been renewed focus on vegetable oils and animal fat bio diesel.

An acceptable alternative fuel for engine has to fulfill the environmental and energy security needs without sacrificing operating performance. Vegetable oils can be successfully used in CI engines through engine modifications and fuel modifications. Engine modifications include dual fueling, injection system modifications; heated fuel lines etc. fuel modifications include blending of vegetable oils with diesel, transesterification, cracking/pyrolysis, micro emulsion, and hydrogenation to reduce polymerization and viscosity. From amongst large number of vegetable oils available in the world, if any specific oil needs to be adapted as a continuing energy crop, it is then essential that an oil seed variety having higher productivity and oil content must be produced. Technologies must be developed for the use of vegetable oils as an alternative diesel fuel that will permit crop protection to proceed in an emergency situation. Vegetable oil in its raw form cannot be used in engines. It has to be converted to a more engine-friendly fuel called bio diesel. System design approach has taken care to see that these modified fuels can be utilized in the existing diesel engine without substantial hardware modification

|

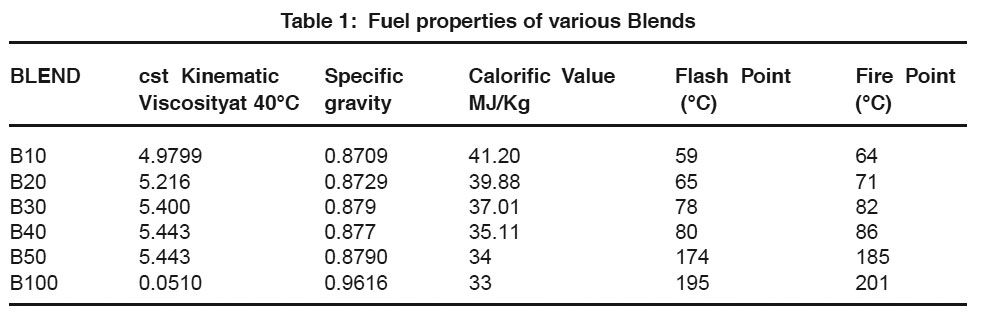

Table 1: Fuel properties of various Blends Click here to view table |

|

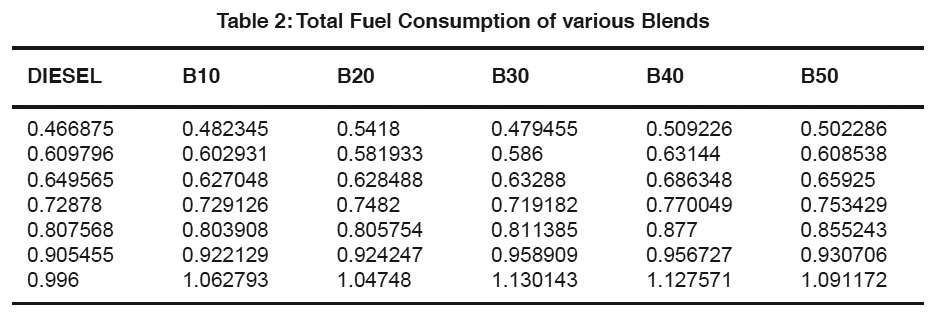

Table 2: Total Fuel Consumption of various Blends Click here to view table |

With agricultural commodity prices approaching record lows, and petroleum prices approaching record highs, it is clear that more can be done to utilize domestic surpluses of vegetable oils while enhancing our energy security. Because biodiesel can be manufactured using existing industrial production capacity, and used with conventional equipment, it provides substantial opportunity for immediately addressing our energy security issues. In the past many non-edible oils were used to run the diesel engines such as sunflower oil, soya bean oil, neem oil, etc,. These edible oils are used to run the diesel engine and their blends with diesel are tested for performance. Methyl esters produced from the vegetable oils cannot compete economically with the hydrocarbon based fuels. Their prices are about 2 to 3 times the cost of the diesel fuel. The non-edible oils such as jatropha, pongamia, neem, etc, are easily available in many parts of the world, and are now cheaper compared with edible oils due to increase in the rate of production. Most of the non-edible oils are not used as biodiesel although they are produced in large quantity.

|

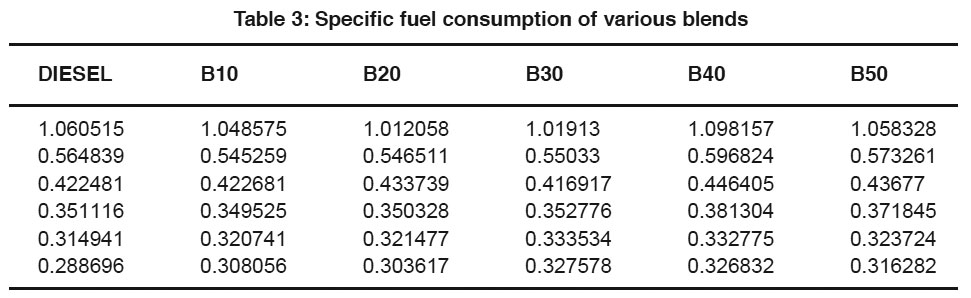

Table 3: Specific fuel consumption of various blends Click here to view table |

Experimental

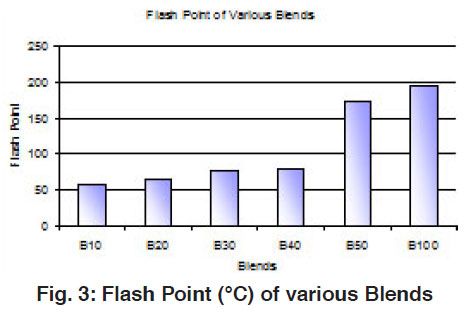

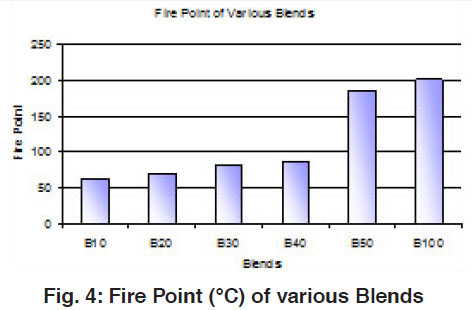

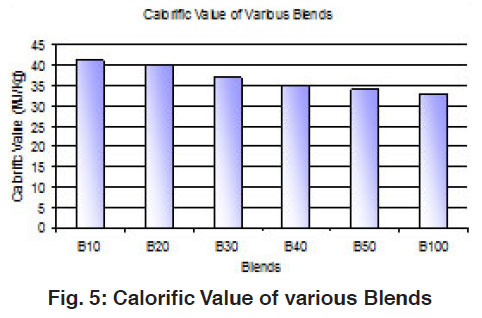

Methyl esters of jatropha carcass are obtained from transesterification process. Then the transesterified oil is mixed with diesel on mass basis. The fuels properties such as flashpoint, fire point, calorific value and density were determined for the blends using appropriate apparatus. Methyl esters obtained from the non-edible oil was tested as diesel fuel blends of 10%, 20%, 30%, 40%, 50% with petroleum diesel fuel were tested in a diesel engine. A stationary engine was mounted on a test bench and prepared for operating in steady conditions. The engine performance of diesel and various blends of jatropha with diesel were tested at constant speed. The compact and simple engine test rig consisting of a four stroke, single cylinder, water-cooled, constant speed diesel engine coupled to a electrical resistance loading. Continuous water supply arrangement is provided to the engine for cooling. The panel houses a water manometer and burette with a three-way cock. The following table provides specification of the engine setup.

Engine Specification Details

BHP : 5 hp @1500 rpm

Speed : 1500 rpm

Bore : 80 mm

Stroke : 110 mm

Fuel : High speed diesel

Loading : Electrical dynamometer

Cooling : Water cooling system

Lubrication : Forced type.

Results

Fuel Properties of Various Blends

|

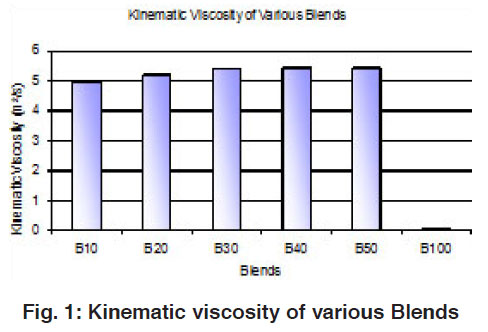

Figure 1: Kinematic viscosity of various Blends Click here to view figure |

|

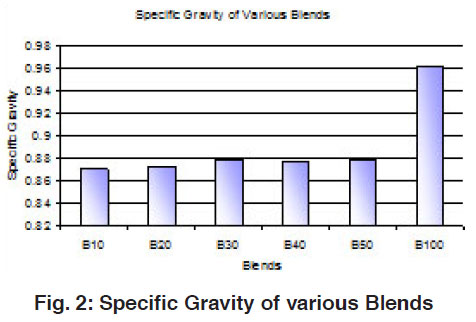

Figure 2: Specific Gravity of various Blends Click here to view figure |

|

Figure 3: Flash Point (°C) of various Blends Click here to view figure |

|

Figure 4: Fire Point (°C) of various Blends Click here to view figure |

|

Figure 5: Calorific Value of various Blends Click here to view figure |

|

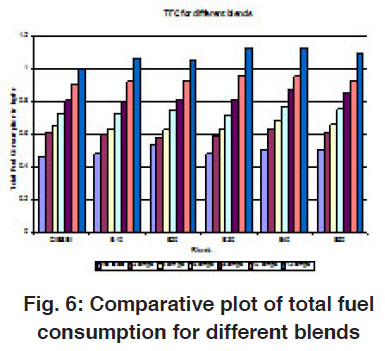

Figure 6: Comparative plot of total fuel consumption for different blends Click here to view figure |

|

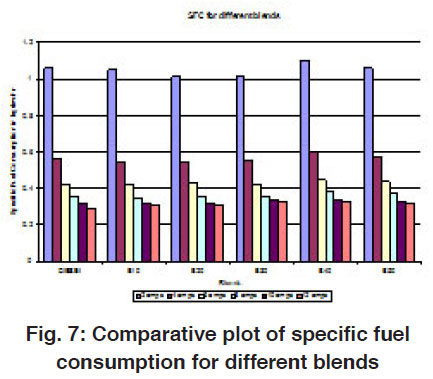

Figure 7: Comparative plot of specific fuel consumption for different blends Click here to view figure |

|

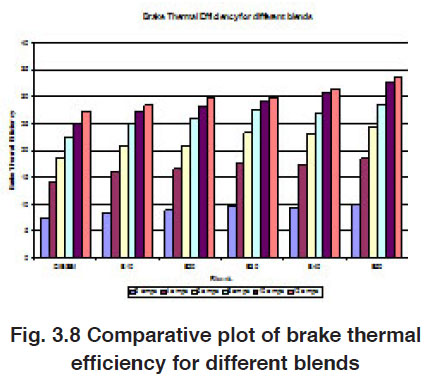

Figure 8: Comparative plot of brake thermal efficiency for different blends Click here to view figure |

|

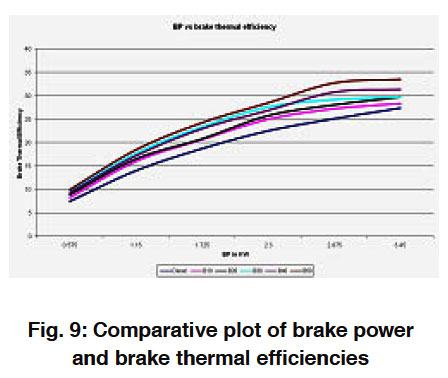

Figure 9: Comparative plot of brake power and brake thermal efficiencies Click here to view figure |

|

Figure 10: comparative plot of brake power and specific fuel consumption Click here to view figure |

Discussion

A series of performance test were carried out using diesel and various blends of jatropha biodiesel were taken at various load conditions. The viscosity of vegetable oil reduces substantially after transesterification.

The density and viscosity of jatropha methyl ester formed after transesterification were found to be close to those of petroleum diesel. The TFC for different blends shows that the total fuel consumption is decreased at the maximum load for the blend B20.The total fuel consumption for the remaining blends are closer to diesel.

|

Table 4: Brake thermal efficiency of various Blends Click here to view table |

The specific fuel consumption for various blends of jatropha is closer to diesel and in particular B20 has lesser SFC than the other blends. The mechanical efficiency of diesel is good, but it decreases with increase in blend ratio. The Blend B20 shows the better brake thermal efficiency when compared to other blends. Similarly the Specific fuel consumption for the blend B20 is lesser comparing with other blends for the given Brake Power.

Conclusion

Based on the performance tests, it is observed that jatropha based biodiesel can be adopted as an alternative fuel for the existing conventional diesel engines without any engine modifications in the system. The viscosity of vegetable oil reduces substantially after transesterification, the density and viscosity of jatropha methyl ester formed after transesterification were found to be close to those of petroleum diesel. The diesel engine can perform satisfactorily on biodiesel fuel without any hardware modifications. The brake thermal efficiency of biodiesel B50 is high. The mechanical efficiency of biodiesel blends decreases with increase in blend ratio of diesel. The specific fuel consumption of diesel and biodiesel blends up to B50 remains closer to diesel. The total fuel consumption of the B20 is high and the other blends are closer to the total fuel consumption value of diesel.

Acknowledgements

The author wishes thank Dr. T. Senthilkumar, Head, Department of Automobile Engineering, Anna University Tiruchirappalli, Tiruchirappalli – 620 024, for his able guidance and motivation to carryout this project.

References

- Hunke, A.L., and Barsic, N.J. "Performance andemission characteristics of a naturally aspirateddiesel engine with vegetable oils (Part-2)". SAEPaper No 810955 (1981).

- Gerhard Vellguth, "Performance of vegetable oilsand their monoesters as fuel for diesel engines". SAE Paper No 831358, (1983).

- Gopalakrishnan. K.V., and Rao. P.S. “Use of nonediblevegetable oils as alternate fuels in dieselengines”. DNES Project report, I.C.E.lab, IIT Madras-36 (1996).

- Ghazi, A.Karim., and Amoozegar, N, "Determinationof the performance of a dual fuel diesel engine withaddition of various liquid fuels to the intake charge". SAE Paper No 830265 (1983).

- Ghazi.A.Karim. "The Dual fuel engine", A chapter inAutomotive engine alternatives, Edited by R.L.Evansbleham press (1987).

- Naser.D., and Bennet.K.F, "The operation of dualfuel compression ignition engines utilizing diesel andmethanol". Proceedings of the IV internationalsymposium on Alcohol fuels technology. (1980).