Review and Concept Development for Electricity Generation from Municipal Solid Waste Using Mfcs

Jahangeer 1 * , Pankaj K Gupta 1 , Shaktibala 2 and Shamim A Rayani 3

1

Department of Hydrology,

Research Scholar,

IIT Roorkee,

247667

India

2

Department of Civil Engineering,

SBCET,

Jaipur,

302013

India

3

Manager Safety,

Voltas Ltd,

Jajpur,

755026

India

Corresponding author Email: jahangeer.tomar@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.11.2.08

The aim of this manuscript is to review and conceptualization of electricity generation from solid waste using Microbial Fuel Cells (MFCs) technology. MFCs technology has an ample future for both waste remediation and renewable energy generation due to an aerobic microbe produces less sludge in MFCs compared with conventional methods. Electricity can be generated from different organic matters such as fatty acids, proteins, wastewater, and carbohydrates etc. Elegant energy can be generated which helps for compensating the costs. The performance of MFCs depends on the system architecture, internal resistance, species and amount of bacteria on the anode, type of organic matter, chemical characteristics of the medium (pH, solution conductivity and chemical concentration) and the electrode surface characteristics. One set of practical experiment was performed using single chamber MFCs and the power generation along with COD removal was measured. The results show significant power generation and effective COD removal parallel in MFC cell. This study will help in design and research for renewable energy production and waste management.

Copy the following to cite this article:

Jahangeer, Gupta P. K, Shaktibala, Rayani S. A. Review and Concept Development for Electricity Generation from Municipal Solid Waste Using Mfcs. Curr World Environ 2016;11(2) DOI:http://dx.doi.org/10.12944/CWE.11.2.08

Copy the following to cite this URL:

Jahangeer, Gupta P. K, Shaktibala, Rayani S. A. Review and Concept Development for Electricity Generation from Municipal Solid Waste Using Mfcs. Curr World Environ 2016;11(2). Available from: http://www.cwejournal.org/?p=16090

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2016-07-21 |

|---|---|

| Accepted: | 2016-08-22 |

Introduction

Both, the demand of energy, and the amount of waste dissipated are ever increasing with the increase in population. The annual estimates from various studies suggest that MSW generation in India ranges between 40 MT and 55 MT.1 Along with the increase in waste generation there is also change in the composition of waste generation.2 Recently IPCC 2007 reports show the maximum methane (25 times greater GHP) generated from South Asia due to rice food waste. Microbial fuel cell (MFCs) technology has an ample future for both waste remediation and renewable energy generation due to an aerobic microbe produces less sludge in MFCs compared with conventional methods. Electricity can be generated from different organic matters such as fatty acids, proteins, wastewater, and carbohydrates etc., and Omission of gas treatment. Elegant energy can be generated which helps for compensating the costs.3

Objectives

To concept development for electricity generation from solid waste using construct single chambered and multiple chambered MFCs which can be run in parallel under different set of conditions/substrates.

Microbial fuel cells

The Microbial fuel cells (MFCs) is emerging technology to support the generation of renewable energy from waste. The performance of MFCs depends on the system architecture, internal resistance, species and amount of bacteria on the anode, type of organic matter, chemical characteristics of the medium (pH, solution conductivity and chemical concentration) and the electrode surface characteristics. With the consideration of above parameters, the single MFC generates a maximum working voltage of 0.3-0.7 V (theoretically 1.23V in case of air as catholyte) due to redox potential between the respiratory enzymes of anodophilic bacteria and cathodic reactant, suggesting the electricity production is limited.4

A typical MFCs has two chambers, which contains an anode in one chamber and a cathode electrode in another.5 An electron donor on the anode side, often hydrogen or methanol, is oxidized on the anode surface, leads to the accumulation of electrons and cations. The electrons captured by the anode create current in the circuit. A potential difference across the circuit is the active force for the reaction. The anodic cations then traverse through selective membrane to the cell cathode side, in order to level the charge transported by the electrons.6 In some cells, an anionic shift from the cathode to the anode occurs during process. When the cathode oxidized by the electrons, power is created due to redox reactions during second step on the anode, and require oxidized electron acceptor.

Mechanisms of MFCs

In anaerobic process, the rate of oxidation for a fuel increases with catalysts. As the growth rate of organisms increases the rate of oxidation increases hence the time taken to treat the waste water also decreases. Whatever the quantity of electrons generated at anode will be transferred through an external load circuit, which has resistance to the cathode. Whereas proton diffuses across a proton exchange membrane or proton permeable membrane (PEM) to cathode side where reduced oxygen is converted into water through a catalyzed reaction as shown in equation1.7

(CH2O) n + nH2O nCO2 + 4ne- + 4nH+ (Anode Oxidation reaction)

4e- + 4H+ + O2 2H2O (Cathode Reduction reaction)

Equation 1: Reduced oxygen is converted into water through a catalyzed reaction

By means of microbiological fermentation, a whole range of bio fuels and related bio products can be obtained from organic biomass present in solid waste and wastewater.8,9 Considering glucose as the primary building mass of material of biomass, one can compare the stoichiometry reactions for the generation of bio-ethanol, biogas (CO2 and CH4) and hydrogen gas with the overall reaction taking place in a microbial fuel cell (as shown in equation2):

Bio-ethanol

C6H12O6-------------------------→ 2C2H5OH + 2CO2

Biogas

C6H12O6-----------------------→3CH4 + 3CO2

Hydrogen gas

C6H12O6 + 6 H2O -------------------→H2 + 6CO2

Microbial fuel cell

C6H12O6 + 6O2 ----------------------------------→6H2O + 6CO2

Equation 2: comparison of Stoichiometry reactions for the production of bio-ethanol, biogas (CO2 and CH4) and hydrogen gas with MFC.

The study shows, in the membrane-less system, the maximum power density obtained is 494 mW/m2whereas in a cell with PEM, it is 262 mW/m2 .10 Fan et al (2007) shows that the separation of anode and cathode by two layers of j-cloth instead of PEM; causes little more additional ionic resistance, decreasing the diffusion of oxygen in to the MFC which in turn causes a drastic increase of power production.11,12,13

Power Densities of MFC’s

The literature on power densities of MFC’s mostly depend on the type of fuel used, type of reactors used and its configuration as shown in Table 1.

Table 1: Comparison of power density with different type of microorganisms, substrates and anodes

|

Microorganism |

Substrate |

Anode |

Current (mA) |

Power (mW/m2) |

Reference |

|

Shewanella putrefaciens |

lactate |

woven graphite |

0.031 |

0.19 |

[8] |

|

Geobacter sulfurreducens |

acetate |

graphite |

0.4 |

13 |

[14] |

|

Rhodoferax ferrireducens |

glucose |

woven graphite |

0.2 |

8 |

[15] |

|

Rhodoferax ferrireducens |

glucose |

porous graphite |

0.57 |

17.4 |

[15] |

|

Rhodoferax ferrireducens |

glucose |

graphite |

74 |

33 |

[15] |

|

Mixed seawater culture |

acetate |

graphite |

0.23 |

10 |

[16] |

|

Mixed seawater culture |

sulphide /acetate |

graphite |

60 |

32 |

[17] |

|

Mixed active sludge culture |

acetate |

graphite |

5 |

- |

[18] |

|

Mixed active sludge culture |

glucose |

graphite |

30 |

3600 |

[19] |

Table 2: Different mediators used in MFC’s

|

MFC Feed |

Anode |

Cathode |

Mediators |

Peak V |

Peak I |

Power density |

|

Wastewater |

Graphite |

Graphite |

Mediator less |

423 |

1.6 |

|

|

Acetate with geobacter sulfurrenducens |

Carbon paper |

Mixture of Pt./C |

Mediated |

0.20 -0.24 |

430 mW |

|

|

Leachate |

Graphite plate & rod |

Platinum |

Mediator less |

438 |

742 mW |

|

|

Dairy waste (yogurt) with microbes from garden compost |

Graphite |

Platinum |

Mediator less |

1450 mAm-2 |

||

|

Domestic waste water |

granular graphite |

Plain granular graphite |

Mediator less |

223 |

15.36 |

19.53 mWm-3 |

|

MFC with microbial catalyzed cathode |

Graphite fibers |

Graphite fiber brushes |

Mediator less |

0.324 |

117.2 mAm-3 |

24.7 mWm-3 |

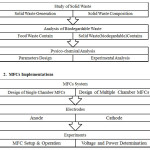

Framework

Solid Waste: Characterizations

|

|

Remediation Determination

|

|

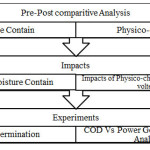

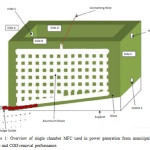

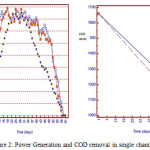

Performance Analysis of Single chamber MFCs for Power generation and COD removal: Case Study

A single chamber MFCs was developed having the 120 cm by length and 60 cm wide and 60 cm by height using glass frame. The anode and cathode were installed inside the chamber and packed with air tight materials. The 10kg collected municipal waste was initially taken in chamber along with one-liter water. The single chamber MFC was fed with approximately 7.8 kg of biodegradable waste with initial COD 1660mg/G. From the graph1, it was observed that, the voltage readings were low initially but improved as the experiment continued. This was because of oxidation of organic matter by the biofilm formed on the electrode. After day 10, increase in the voltage generation was noted 0.82V. Voltage in MFC was almost stable for next 20 days. The increase in the voltage suggests that the bacteria settled into a structured bio-film. After day 30, a slight decrease in voltage was noticed till day 65. Voltage remained constant at 0.6V till day 95.

|

|

In the last few days voltage reduced significantly and dropped to 0V. MFC sustained for 109 days, with peak voltage of 0.86V and an average of 0.6V. MFC showed stable performance for about 66 days. The average power 6 cm below the top cell was obtained as 1.071x10-7 W and the 6 cm above the bottom of cell average power obtained in the MFC was 1.87373x10-7 W. i.e. the energy produced by the anode, placed at the top of the cell was higher than the anode placed at the bottom of the cell which indicates that the placing of anode plays a key role in production of electrical energy. The power generation and COD was measured per day in upcoming 60 days. The results show the power generation increases with time and reached to peak after 16 days and was continue to 40 days. Parallel to generation, COD was observed decreasing continuously.

|

|

Conclusion

MFC designs need improvements before a marketable product will be possible. Issues of the scale up of the process remain critical issues. While full-scale, highly effective MFCs are not yet within our grasp, the technology holds considerable promise, and major hurdles will undoubtedly be overcome by engineers and scientists. The growing pressure on our environmental issues and the call for renewable energy sources will fulfill the future needs. Furthermore, development of this technology, leading soon to its successful implementation in practical purposes for the wastewater treatment and energy production.

Therefore, the aim of this study was to investigate the power generation and COD removal preformation analysis using single chamber MFC in laboratory. A small scale MFC was fabricated having anode and cathode. The municipal waste was used to cell along with optimal amount of water. The electricity generation and COD removal was measured on daily basis. The results shows the effective power generation along with COD removal. It is observed that having good network of anode electrodes i.e. anode in good contact with substrate, will reduce the losses to some extent. Maintaining suitable environmental conditions like DO, temperature and pH can help optimize the yield from such cells. This study will help in future renewable energy generation as well as sustainable waste management.

References

- http://cpcb.nic.in/php/2005

- http://cpcb.nic.in/cited on date 02/04/2016

- Jahangeer, Pankaj Kumar Gupta, Vikram Kumar, Shashi Ranjan and Shaktibala. “Identification of hotspot of aquifer contamination using geophysical investigation”. J. innov. res. appl. Sciences 2(9): 381-390 (2016)

- Pinto, R. P., B. Srinivasan, A. Escapa, and B. Tartakovsky. "Multi-population model of a microbial electrolysis cell." Environmental science & technology 45, (11): 5039-5046 (2011)

CrossRef - He, Zhen, Haibo Shao, and Largus T. Angenent. "Increased power production from a sediment microbial fuel cell with a rotating cathode." Biosensors and Bioelectronics 22, (12): 3252-3255 (2007)

CrossRef - Kim, Byung Hong, H. S. Park, H. J. Kim, G. T. Kim, I. S. Chang, J. Lee, and N. T. Phung. "Enrichment of microbial community generating electricity using a fuel-cell-type electrochemical cell." Applied Microbiology and Biotechnology 63, (6): 672-681 (2004)

CrossRef - Cheng, Shaoan, Hong Liu, and Bruce E. Logan. "Increased performance of single-chamber microbial fuel cells using an improved cathode structure." Electrochemistry Communications 8, (3): 489-494(2006)

CrossRef - Kim, Hyung Joo, Hyung Soo Park, Moon Sik Hyun, In Seop Chang, Mia Kim, and Byung Hong Kim. "A mediator-less microbial fuel cell using a metal reducing bacterium, Shewanella putrefaciens." Enzyme and Microbial Technology 30, (2): 145-152 (2002)

- Kim, Jung Rae, Giuliano C. Premier, Freda R. Hawkes, Jorge Rodríguez, Richard M. Dinsdale, and Alan J. Guwy. "Modular tubular microbial fuel cells for energy recovery during sucrose wastewater treatment at low organic loading rate." Bioresource technology 101, (4): 1190-1198 (2010)

- Liu, Hong, Ramanathan Ramnarayanan, and Bruce E. Logan. "Production of electricity during wastewater treatment using a single chamber microbial fuel cell." Environmental science & technology 38, (7): 2281-2285 (2004)

- Fan, Yanzhen, Hongqiang Hu, and Hong Liu. "Enhanced Coulombic efficiency and power density of air-cathode microbial fuel cells with an improved cell configuration." Journal of Power Sources 171, (2): 348-354 (2007)

- Dumas, Claire, Alfonso Mollica, Damien Féron, Régine Basséguy, Luc Etcheverry, and Alain Bergel. "Marine microbial fuel cell: use of stainless steel electrodes as anode and cathode materials." Electrochimica Acta 53, (2):468-473 (2007)

- Dumas, Claire, Régine Basseguy, and Alain Bergel. "Electrochemical activity of Geobacter sulfurreducens biofilms on stainless steel anodes." Electrochimica Acta 53, (16):5235-5241 (2008)

CrossRef - Bond, Daniel R., and Derek R. Lovley. "Electricity production by Geobacter sulfurreducens attached to electrodes." Applied and environmental microbiology 69, (3): 1548-1555 (2003)

CrossRef - Chaudhuri, Swades K., and Derek R. Lovley. "Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells." Nature biotechnology 21, (10):1229-1232 (2003)

CrossRef - Bond, Daniel R., Dawn E. Holmes, Leonard M. Tender, and Derek R. Lovley. "Electrode-reducing microorganisms that harvest energy from marine sediments." Science 295, (5554): 483-485 (2002)

CrossRef - Tender, Leonard M., Clare E. Reimers, Hilmar A. Stecher, Dawn E. Holmes, Daniel R. Bond, Daniel A. Lowy, Kanoelani Pilobello, Stephanie J. Fertig, and Derek R. Lovley. "Harnessing microbially generated power on the seafloor." Nature biotechnology 20, (8): 821-825 (2002)

CrossRef - Lee, Jiyoung, Nguyet Thu Phung, In Seop Chang, Byung Hong Kim, and Ha Chin Sung. "Use of acetate for enrichment of electrochemically active microorganisms and their 16S rDNA analyses." FEMS Microbiology Letters 223, (2): 185-191 (2003)

CrossRef - Rabaey, Korneel, Peter Clauwaert, Peter Aelterman, and Willy Verstraete. "Tubular microbial fuel cells for efficient electricity generation." Environmental science & technology 39, (20): 8077-8082 (2005)

CrossRef