Estimation of Filtration Potential of an Effective Biosand Filter for Removal of Iron, Turbidity From Various Sources of Water

Lopa Sarkar1 * , S. K. Biswal1 , R. K. Panigrahi1 and Bikash Sarkar2

1

Centurion University of Technology and Management (CUTM) Bhubaneswar,

Khordha,

Odisha,

752050

India

2

ICAR Research Complex for Eastern Region,

Patna,

Bihar

India

Corresponding author Email: lopagsarkar@yahoo.com

DOI: http://dx.doi.org/10.12944/CWE.10.2.31

A study has been conducted for designing, constructing and evaluating of an effective biosand filter. Different types of charcoal mixture such as bamboo, coconut and wood and carbon mat as an important filter media was used for the modification of biosand filter. The filter had seven layers with gravel, sand, carbon mat and charcoal which were responsible for filtration process. The filtered water analysed in every 20 min interval. The raw ground water pH was 6.12 while it passes through bamboo, coconut and wood mixture filter, the filtered water showed higher pH value. The filter in which mixture of charcoal used as filter media showed better removal efficiency of turbidity compared to control filter without charcoal and mat. The value of turbidity in filtered water of charcoal mixture filter was below 2 NTU which is the permissible limit of drinking water according to World Health Organization but for control it was average 14 NTU. Initially the flow rate was higher and gradually decreases with time. The flow rate of the Biosand filtered water decreases significantly with increase in turbidity. The charcoal based filter showed better removal of iron (II) (95-98%) compared to control (73-76%). The charcoal based filter resulted tastier water by enriching of water with mineral like sodium and potassium.

Copy the following to cite this article:

Sarkar L, Biswal S. K, Panigrahi R. K, Sarkar B. Estimation of Filtration Potential of an Effective Biosand Filter for Removal of Iron, Turbidity From Various Sources of Water. Curr World Environ 2015;10(2) DOI:http://dx.doi.org/10.12944/CWE.10.2.31

Copy the following to cite this URL:

Sarkar L, Biswal S. K, Panigrahi R. K, Sarkar B. Estimation of Filtration Potential of an Effective Biosand Filter for Removal of Iron, Turbidity From Various Sources of Water. Curr World Environ 2015;10(2). Available from: http://www.cwejournal.org/?p=11

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2015-04-20 |

|---|---|

| Accepted: | 2015-06-06 |

Introduction

In Many developing and under developing countries are facing water problems due to lack of clean supplied water. It is reported that more than 1.1 billion people are suffering health problems for consuming unsafe water.1,2 About 74% of India’s total population, currently about 1.25 billion, live in rural areas. More than one third of the water available to them is not potable. In a grim reminder that poor quality of drinking water leads to serious health problems.3 The major water pollutants coliform bacteria, iron, fluoride create severe health hazards and as research depicts about 80% of communicable diseases in the world are waterborne.4, 5 Odisha has reported multiple contaminations such as excess iron, manganese, fluoride, turbidity and pathogens and there is no doubt that current water situation in some parts of Khurda district of Odisha will get much worse unless suitable solutions are sought. An effective water purifier was developed which can reduce colour and turbidity, pathogenic organisms and chemical contaminants through extensive research.6 Most existing purification methods not only remove the impurities but drain out the essential minerals as well.3 Moreover they are expensive and require extensive maintenance. Therefore there is an obvious need to assess community prepared charcoal (bamboo, coconut and wood) scientifically for its potential to remove dissolved iron, turbidity and pathogenic organisms from drinking water.7 The Biosand filter was developed by Dr Eric Manz and has been established in many countries.8 The filtration processes in biosand filter includes settlement, straining, filtration, removal of organics, inactivation of micro organisms and chemical change.9 Directly water is poured into the filter without any treatment for downward movement. Without any treatment directly water is poured into the filter for downward movement.10 The removal of various pollutants such as turbidity (upto 1 NTU) dissolved organic carbon (15 to 25%), iron (90 to 95), organic and inorganic toxicants (50 to 90%) through biosand filter was reported by many authors.11,12 A complex biological layer is the most important component in biosand filter which provides effective purification, whereas underlying sand is the present support medium.9 Efficiency of the filter was found for the removal of turbidity, arsenic, iron and microbial contaminants by incorporating zeolite material as filter media.13 Since in Khordha district mainly in rural areas people are very much affected by iron rich ground water, yet there is a need to design a modified biosand filter containing various types of charcoal mixture (bamboo, coconut and wood) as filter media along with sand, gravel and carbon mat to provide many other complex and expensive substitute water purifiers.

The main objectives of the present study were to study;

The turbidity and iron removal efficiency of biosand filter from various sources of waterDeterminations of flow rate of biosand filter using various turbid water.

Materials and Methodology

Design and Description of Filter

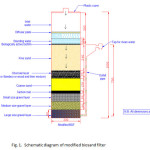

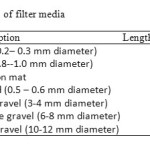

The schematic diagram of modified biosand filter is shown in Fig.1. The biosand filter was fabricated from rigid PVC pipe (4 kg/cm2) of 10 mm wall thickness. The height of the filter was maintained 1.0 m and its diameter 0.30 m. The bottom end was closed by PVC sheet and top was fitted with lid having diameter is 0.30 m. A diffuser plate was made from PVC sheet and fitted into the filter. Circular holes were made to the diffuser plate to maintain a steady water flow rate and entrapping the larger particles like grass and leaves. The filter consists of seven zones which help for the filtration process. The description of various filter media is given in Table 1. All the filter media like large, medium and small size gravel were kept in nylon net bag. The coarse sand, fine sand, charcoal and their mixture were filled in Nylo-bolting (Fine mesh) cloth bag (Fig.2a). 25 mm carbon mat was also used as media. The necessary fittings like water inlet and outlet was fitted into the filter (i.e. complete filter) as per design specification. The first zone is the raw water which is to be used for filtration process. The second zone is the standing water zone (5 cm above the sand surface). The third zone is the biological layer which consists of sediments and microorganisms to help the removal of iron and pathogenic organisms.14

|

Figure 1: Schematic diagram of modified biosand filter Click here to View figure |

|

|

The sand zoneis of the filter is assigned as fourth zone which fourth zone consists of coarse sand and fine sand. The fifth zone is charcoal zone which is in between coarse sand and fine sand. The sixth zone is carbon mat and the seventh zone is gravel zone composed of large size, medium size and small size. 300 ml of water was supplied for two days interval to maintain constant water level. A filter without charcoal media and carbon mat was used as control for the experiment. Two replications were maintained for each media. Total seven filters were conducted on control and experimental unit.

|

|

Water Sample Collection

Different turbid iron rich water samples were collected from tube wells and river of various locations of Khordha District, Odisha. Various water quality parameters were determined immediately at the environmental laboratory, Centurian University of Technology and Management. All water quality parameters are measured by standard methods.15

Filtration Procedure

The removal efficiency of iron and turbidity through Biosand filter was evaluated using various sources of water (groundwater and surface water). All filtration were conducted in gravity flow mode. Purification of turbid water was done in the laboratory of Centurian University of Technology and Management, Khordha for 12 months. Before starting filtration, 20L river water is poured by adding small quantities of nitrogen (NH4Cl) and phosphorus (KH2PO4) to ensure the formation of biolayer. It may take up

to 15 days for the biolayer to fully form. Throughout the filtration procedure, the water temperature was about 18+1oC while the room temperature was about 25+2oC. The amount of dissolved oxygen levels in water sample throughout the filter depth was always between 6.52 and 6.74 mg/l in both control and experimental biosand filter. The collected iron rich turbid water is allowed to pour into the top of biosand filter on an intermittent basis. The water slowly passes through the diffuser plate, biolayer, sand, adsorbent, mat and gravel layer. The flow of water finally stops. The standing water layer will be at the higher height as the outlet of the pipe. The filtered water naturally flows from the outlet tube (Fig. 2a). Filtration was carried out for 2 h period to get enough purified water. Different quantities of filtered water collected in every 20 minutes interval over the 2 h period of filtration. The concentration of dissolved oxygen in the filtered water was almost same in both control and all experimental filters. This was done to get the chemical contaminant difference between before filtration and after filtration. The filtered water samples were analysed to determine the water quality parameters. The physicochemical characteristics of ground water before filtration and after filtration by biosand filter is given in Table 2.

Table 2: The physicochemical characteristics of ground water before filtration and after filtration by Biosand filter.

|

Sl. no. |

Parameters |

Before filtration |

After filtration Control Charcoal media filter |

|

1 |

pH |

6.12+0.12 |

6.64+0.24 7.12+0.13 |

|

2 |

Turbidity (NTU) |

165+2.44 |

18.0+0.32 2.0+0.11 |

|

3 |

Total Hardness(mg/l) |

296+3.12 |

112+4.3 65+1.16 |

|

4 |

Total dissolved solids (mg/l) |

480+4.48 |

184+6.26 54+2.24 |

|

5 |

Alkalinity (mg/l) |

98+2.12 |

124+3.45 146+2.18 |

|

6 |

Chloride (mg/l) |

116+3.32 |

84+2.46 48+2.54 |

|

7 |

Dissolved oxygen (mg/l) |

6.52+0.32 |

6.76+0.26 6.76+0.22 |

|

8 |

Sodium (mg/l) |

25.06+2.56 |

32+3.44 56+2.34 |

|

9 |

Potassium (mg/l) |

7.33+2.16 |

12+1.16 28+3.26 |

Values are (Mean+ SE),N=3; Turbidity unit is in NTU. All values are statistically significant (p<0.05).

Determination of Flow Rate with Turbid Water

To determine the flow rate of biosand filter with various levels of turbid water; the inlet reservoir is to be full of water. The flow rate of biosand filter was measured with various sources of water (river water, tube well water, bore well water and pond water). One control filter without charcoal along with three filters with charcoal mixture as filter media was run to see the removal efficiency of turbidity. The flow rate of biosand filter was determined by measuring filtered water volume (L) per unit time (min) taken to filter it. The flow rates were measured every 20 minutes over 2 hours. Triplicate readings were taken for each sample for data analysis.

Results and Discussion

The amount of iron and turbidity was determined separately in every 20 mins interval during the filtration process. The physicochemical parameters of water before and after filtration were given in Table 2. There is a significant differences (R2=0.99) between before and after filtration for all parameters. The source water pH was found to be 6.12 and filtered water was found to be 6.64 and 7.12 for control and bamboo, coconut and wood mixture, respectively. The amount of dissolved oxygen in the filtered water was varied from 6.52 to 6.67 mg/l in both control and charcoal media filter which helps to oxidize Fe (II) to Fe (III) forming Fe (OH)3 .16 There was a significant difference of iron removal between charcoal mixture filter and control filter given in Table 3.

Table 3: Residual irons (mg/l) of filtered water by Biosand filter with an initial concentration of 6 mg/l and flow rate of 0.9 L/min. All are mean values.

|

Run time (min) |

Residual iron (mg/l) without charcoal BSF filter |

Residual iron (mg/l) with charcoal BSF filter Bamboo, coconut & wood mixture |

|

20 |

2.6+0.16 |

0.38+0.11 |

|

40 |

2.2+0.18 |

0.32+0.06 |

|

60 |

2.2+0.22 |

0.32+0.04 |

|

80 |

1.8+0.24 |

0.28+0.06 |

|

100 |

1.6+0.20 |

0.22+0.05 |

|

120 |

1.6+0.18 |

0.20+0.04 |

Charcoal based residual iron values is significantly (p<0.05),different from control filtered water. Correlation coefficient (R2 =0.99).

After filtration of 120 min the minimum residual iron values of 0.22 and 1.6 mg/l for charcoal mixture and control filter, respectively. The charcoal media filter showed significantly better performance compared to control filter. The dissolved form of Fe (II) changes to insoluble form Fe (III) with change in pH and dissolved oxygen (DO) levels. Before filtration pH of water was found to be 6.12 and filtered water was close to neutral. Charcoal mixture filter showed slightly higher pH value compared to control filter. It was observed that pH above 6 leads to decrease in adsorption of Fe (II) ion at adsorbent-adsorbate interface [16]. At higher pH value the removal takes place by adsorption as well as precipitation due to the formation of Fe (OH)3.17 This could be explained with the increase in pH of the solution, OH- ions in the solution increase which form complexes with metal ions and precipitate as metal hydroxide.18 Charcoal media operated filter showed the iron limit up to 0.30 mg/l (permissible limit for drinking water) but in control filter limit is 1.6 mg/l. The iron and other metallic elements will be adsorbed on the tiny surfaces of the adsorbent charcoal layer. Removal of iron level was investigated by soil constructed filter [5] and by trickling filter.19 In both the observation remaining iron amount was found to be less than 0.3 mg/l.

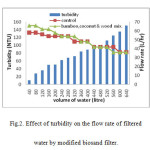

Effect of Turbidity on Flow rate of Biosand Filter

During the study period, 640 l of iron rich turbid ground water was filtered from four different sources of water. Each source of water was filtered four times (40 litres in each time) and duplicate samples were run in another filter. In the first run 160 l of water with low turbidity (10-20 NTU), in the second run 160 l of water with turbidity (20-50 NTU), in the third run 160 l of water with turbidity (50-100 NTU) and in the fourth run 160 l of water with turbidity (100-150 NTU) was filtered. The residual turbidity of filtered water by biosand filter with charcoal and without charcoal is given in Table 4.

Table4: Residual turbidity of filtered water by biosand filter with charcoal media and without charcoal.

|

Sl.no. |

Before filtration turbidity of water (NTU) |

|

|

1 |

10 |

2+0.25 0 |

|

2 |

24 |

2+0.15 0 |

|

3 |

52 |

2+0.44 0 |

|

4 |

66 |

4+0.32 0 |

|

5 |

88 |

6+0.12 0 |

|

6 |

102 |

8+0.64 0 |

|

7 |

126 |

10+0.24 0 |

|

8 |

150 |

14+0.22 1 |

All charcoal based residual turbidity values are significantly (p<0.05) different from control filtered water. Correlation coefficient (R2 =0.99).

From this table it is observed that there is a significant removal of turbidity between before and after filtration of water. There is 96-100% removal of turbidity observed for biosand filter with charcoal as medium whereas 85-90% removal in biosand filters without charcoal.

|

|

The charcoal media mixture filter showed removal of turbidity below 5 NTU which is the standard value of drinking water but without charcoal it was above 5 NTU throughout the study period. Various levels of turbid water were used for filtration through biosand filter with charcoal media and without charcoal. The influence of turbidity on the flow rate of filtered water is given in (Fig. 2). For this study 640 L of iron rich ground water was filtered continuously without cleaning filter. The biosand filter showed maximum flow rates at the beginning of the filtration when turbidity was (10-100 NTU) and the rate have been decreased during filtration process. Similar findings were reported by many authors.9 &13 Biosand filter showed comparatively higher flow rates (average 0.50 to 0.90 L /min) for highly turbid water (100 to 150 NTU) which is higher than the described turbidity limit.13 The flow rate of the filter decreases with an increase in the volume of water filtered.

Conclusion

The efficiency of biosand filter depends on raw water quality and filter design. The charcoal based biosand filter showed better performance towards the removal of iron and turbidity. The filter presented higher flow rates. The use of biosand filter is very much suitable for the larger family, school etc. The modified biosand filter showed higher removal efficiency of chloride, calcium and magnesium but also enriched water with minerals like sodium, potassium and maintain pH of water 6.88 to 7.34 which is suitable for drinking water. Hence it can be used for produce higher quality of water at lower costs. Highly turbid water (100-150 NTU) showed drop in the flow rate of the filter. The flow rate of the biosand filter decreased significantly after continuous use of two months continuously and higher flow rate could be achieved by washing sand layer, carbon mat and charcoal layer. The biosand filter users can use filtered water after one and half hour of pouring water into the filter. This may be recommended that proper care must be taken for washing and moving the filter as there might be disturbed the filter media and the biological layer. The biosand filter becomes cost effective and could be afforded by most rural people in Khordha. The modified biosand filter overcomes some of the limitations of the conventional techniques. The locally available materials are used in the filter to get purified water at reasonable amount of water within a short time. Moreover, this device can be used without any pipe connection and electricity.

Acknowledgment

The authors gratefully acknowledge for financial assistance provided by Department of Science and Technology, Government of India to carry out this experiment.

References

- Ashobolt N.J. Microbial contamination of drinking water and disease outcomes in developing regions. Toxicology, 198, 229-238, (2004).

- World Health Organization (WHO) Global water supply and sanitation assessment 2000 report, January (2004).

- Shwetha kamath k,http://www.indiawaterportal.org/blog/shwetha-kamath k/18965

- Joshi, A. and Chaudhuri M. Removal of arsenic from ground water by iron oxide coated sand ASCE .J Environ Eng. 122 (8) 769-771, (1996).

- Nemade P.D., Kadam M.A. and Shankar H.S. Removal of iron, arsenic and coliform bacteria from water by novel constructed soil filter system. Ecological Engineering, 1152-1157, (2009).

- Sobsey M. Evaluation of the Biosand Filter for reducing risks of Diarrhoeal illness and improving Drinking water quality in communities in the Dominican Republic University of North Carolina, (2004).

- Ahamad,K.U. Kinetics, equilibrium and breakthrough studies for Fe (II) removal by wooden charcoal. A low-cost adsorbent. Desalination, (2010).

- Earwaker P. Evaluation of Household Biosand Filters in Ethiopia Master of Science thesis in Water Management (Community Water Supply). Institute of Water and Environment. Cranfield University Silsoe, United Kingdom. (2006).

- Huisman L. and Wood W. Slow Sand Filtration. WHO, Geneva, (1974).

- Barnes D. and Collin Z. S. The biosand filter. Siphon Filter and Rainwater Harvesting. pp 25-27, (2009).

- Ngai T. and Welewijk S. (2003).The Arsenic Biosand Filter (ABF) Project Design of an Appropriate Household Drinking Water Filter for Rural Nepal Report prepared by RWSSSP and ENPHO, (2003).

- Palmateer G., Manz D., Jurkovic A., Mcinnis R., Unger S., Kwan K.K. and Dudka B. Toxicant and parasite challenge of Manz intermittent slow sand filter. Environ. Toxicol. 14 217-225, (1999).

- Mahlangu O.T.,Monyastsi L.M.,Momba M.N.B. and Mamba B.B. A simplified cost- effective biosand filter (BSFZ) for removal of chemical contaminants from water. J. of Chemical Engineering and Materials Science, vol.2 (10).156-167, (2011).

- CAWST, BioSand Filter Manual Design, Construction, Installation, Operation and Maintenance. (2008).

- American Public Health Association (APHA). Standard Method for the Analysis of Water and Waste water. 17th American Public Health Association, Washington, (1998).

- library.iitb.ac.in

- Xiong R.Wang,Y.,Zhang,X. and Canhui L.Facile synthesis of magnetic nanocomposites of cellolose @ ultrasmall iron oxide nanoparticles for water treatment.RSC, Advances. 2014.

- Mohamed I, Kalad A, Najat J, Rahik A and Jamal A. Development a Commercial Proto type Unit (10 Kg/h) for Production of Activated Carbon Using Iraqi Source Raw Material, ASTF Report No. B-MS13, (2010).

- Tekerlekopoulou A.G.,Vasiliadou I.A. and Vayenas D.V. Physico-chemical and biological iron removal from potable water. Biochemical Engineering Journal 31, 74-83, (2006).