Assessment of Environment Control in Arid Area Green house coupled with Earth Tube Heat Exchanger

Kamlesh R. Jethva 1 * and Girja Sharan 2

Corresponding author Email: kamaljethva@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.11.1.30

In hot arid regions, yields are low and unstable, growing season limited to one. Greenhouses can stabilize and improve yields and extend seasons. But their adoption is impeded by the requirement of large amount of water for (evaporative) cooling. Arid Area Greenhouse (AAG) is developed to reduce or eliminate this need by employing earth-tube-heat-exchanger (ETHE). ETHE was able to heat the greenhouse from 9°C to 22-23°C in 30 minutes in the cold winter nights. Static ventilation along with shading was effective for day time to control till early March. Subsequently ETHE was also operated. Yield of tomato in Arid Area Greenhouse was 1.5 to 2 times and water saving in AAG was 44% of that in open-field condition. ETHE and natural ventilation hold promise as environmental control devices for greenhouses in hot arid regions.

Copy the following to cite this article:

Jethva K. R, Sharan G. Assessment of Environment Control in Arid Area Greenhouse coupled with Earth Tube Heat Exchanger. Curr World Environ 2016;11(1) DOI:http://dx.doi.org/10.12944/CWE.11.1.30

Copy the following to cite this URL:

Jethva K. R, Sharan G. Assessment of Environment Control in Arid Area Greenhouse coupled with Earth Tube Heat Exchanger. Curr World Environ 2016;11(1). Available from: http://www.cwejournal.org/?p=13965

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2016-03-05 |

|---|---|

| Accepted: | 2016-04-13 |

Introduction

Kutch region, in the north-western part of India, is characterized by low and erratic rainfall, high ambient temperatures, salt-affected soils and poor quality water[13]. Open-field cultivation is prone to failures and yields are low[13] Technology that can reduce the risk of crop failure, improve yields and make better use of scarce water would be greatly desirable. Greenhouse technology could help to achieve these goals. But it’s still relatively new in India, and the installations are mostly in colder regions so far. Its potential usefulness in making the hot arid areas more productive has not been appreciated; nor researches carried out to adopt it to such areas. Mears[7] drew attention to this "While a greenhouse is generally regarded as necessary to provide a warm environment in cold climates, it has also been shown that with properly designed cooling system, it is possible to improve plant growing conditions under extensively hot climates. Adaptation of modern cooling technologies to Indian conditions will undoubtedly lead to increased opportunities for production of high value plants and materials in areas where the environment is extremely harsh. Protected cultivation also has the potential benefit of substantially increasing plant productivity per unit water consumption, which is important in many areas where good quality water is severely limited".

Common methods of cooling are fan and pad systems and mist nozzles or foggers. Estimate of water required for cooling under climatic conditions of Bhuj (90 km from the project site) showed that a five month crop needing cooling for about 120 days will use up over 700 mm of water, comparable to that needed in open field. This is one major impediment. Alternative cooling procedure would need less or not water would be desirable. One possible alternative could be the earth-tube-heat-exchanger (ETHE) and natural ventilation may be another.

Greenhouses in the southern Mediterranean area too have the same problem. Kittas et al.[6] observed “Development of the greenhouse area in Mediterranean and arid regions calls for efficient greenhouse summer acclimatization. Natural ventilation is the most common system used for greenhouse cooling”. Cooling needs will be more prolonged in Kutch area. But at the same time it is windy. For instance mean wind velocity during the day (10 am to 4 pm) in the month of April, May and June was 6 m/s, 8 m/s and 9 m/s respectively. Reliance on natural ventilation would also be appropriate, in view of the fact that electricity is expensive and supply unreliable.

Santamouris et al.[11] reviewed a set of eighteen greenhouse installations drawn from different countries using ETHE. In all these it was deployed to supplement heating. The cover it provided to total heating requirement varied from 28% to 60%. In some cases, the performance was stated in terms of increase in greenhouse air temperature over the ambient on coldest days which varied from 3°C to 10°C. They have not mentioned about cooling mode. But they demonstrated via simulation that ETHE would be an equally attractive supplement for cooling. Using TRNSYS simulation were done for a greenhouse coupled to ETHE and operating under Athens (37.50 N lat) environment climatic and ground temperature data of Athens was used. Air temperature of the greenhouse in summers was predicted and compared with measurements from their 1000m2 glass-covered greenhouse at Athens coupled to ETHE. Simulations showed that continuously ventilating the greenhouse with air from the buried pipes will keep the inside air temperature below 40°C. In summers of Athens, temperatures in closed, unventilated greenhouse commonly go up to 45°C. In Kothara (23°14 N lat) a closed house in October, November, December and January showed temperature rise up to 55°C, 38°C, 34°C and 59°C respectively. Here an ETHE might be needed.

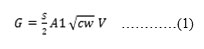

Extensive work on natural ventilation has been reported from the Mediterranean region and some also from parts of the USA. Boulard and Baille[1], Boulard and Draoui[2] developed useful expressions to predict ventilation rates from roof vents after extensive measurements in a 416 m2 two span plastic greenhouse at Avignon (France). One of the several models to compute the ventilation rate, given the roof vent size and wind speed is:

Where,

G = ventilation rate,

S = vent area,

= empirically determined dimensionless coefficient, for wind regimes of 6 to 9 m/s

was determined as (0.20 ± 0.008),

V = Wind speed

Table (1) shows the empirical coefficients determined by several other authors.

Table 1: Empirical Wind-coefficients for Vents without Screens

|

Source |

Roof |

One side |

Both sides |

Roof + one side |

|

Papadakis, et al. (1996) |

0.246 |

0.142 |

- |

0.210 |

|

Kittas, et al. (1996) |

- |

- |

0.230 |

- |

|

Kittas, et al. (2002) |

0.288 (without screen), 0.136 (with screen) |

- |

- |

- |

Kacira et al.[4] used Computational Fluid Dynamics (CFD) software to study air change rates, wind flow patterns in greenhouse of saw-tooth profile with vents on the side and roof. Simulations indicate that air change rate is influenced significantly and positively by the wind speed, location of vents with respect to wind direction. Side vent on the windward side is more effective than the roof vents. For instance, in empty condition in a two span house with external wind of 2 m/s, the air change rate was 4.05 air changes per minute with the windward side vent open along with the two roof vents. Without the side vent, the rate declined to just 0.7 air changes per minute (one sixth of that). The side vent area was 9% of the floor area, each of the two roof vents 12% of the floor. All three vents had an area of 33% of the floor. At slower winds, decline was proportionately greater. The wind flow patterns obtained from simulations are interesting and help in understanding the usefulness of vent size and location.

Openings in the greenhouses are covered with insect-screens, which reduces the ventilation rate significantly as seen from the results of Kittas et al.[5] in Table 1. Miguel et al.[8] tested seven different screen materials, determined pressure drop across screens and estimated the permeability. They showed that the pressure drop was best described by the well known Forcheimer equation. Muñoz[9] developed information on two important parameters i.e. discharge coefficient for the vents and the wind–effect coefficient for the structure needed to compute ventilation rates in a given house for the given vent size and location.

Let us recapitulate, greenhouse technology can improve productivity in hot arid areas. To facilitate its adoption, it would be desirable to develop methods of cooling that require less or no water and that are economical also on electricity use. Efforts are on at several places to adopt natural ventilation in greenhouses in the Mediterranean area to reduce cooling costs. The ETHE and static ventilation appear promising for hot arid areas like Kutch in India. These need to be tried out.

Materials and Methods

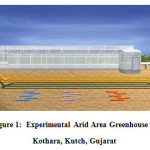

A facility was built at Village: Kothara, Dist.: Kutch of Gujarat, India. Kothara consisting of a greenhouse coupled to ETHE in closed-loop mode and furnished with side and roof vents and retractable shade nets on top. The entire assembly is termed Arid Area Greenhouse (AAG).

Experimental Design of Arid Area Greenhouse

In the year 1998, when our initiative to introduce controlled environment agriculture in the arid region started, there was no local data-base on deep ground temperature regime, nor of course any example of ETHE application in this region. Considerable amount of basic work had to be done to build local data base. First, the deep ground temperature regime was characterized. Sharan and Jadhav[14] reported that the temperature regime at 3 m depth is stable, with mean of 27°C and small seasonal amplitude of fluctuation. Then a single pass ETHE built and tested in heating and cooling mode[13][15] . Then one actual system using ETHE was installed at Ahmedabad Zoo to cool the dwellings of tigers[16]. Experiences from all these were used to design and build the facility at Kothara.

Greenhouse Structure

The greenhouse is a saw-tooth type structure with frames made of square closed structures of galvanized iron. It has 6m span, 20m length and 3.5m height at the ridge; with floor area of 120m2 and enclosed volume 360m3 (Figure 1). The gutter is east-west oriented. 200 micron UV stabilized PE film used for cladding.

|

|

Vents

Although some work has been initiated, there are as yet no standards for air change rates for naturally ventilated greenhouses in India. The ASAE standard is 0.75 – 1 air change per minute. Equation-2 gives the relation between the air flow rate and the heat to be removed (ASHRAE1985 Fundamentals),

H

Q = -------------------------- .............. (2)

(Cf2) (Ti – To)

Where,

Q = air flow rate (m3/h),

H = heat to be removed from the space (W),

Cf2 = computational coefficient (0.34),

Ti and To = temperatures of inside and outside space (K).

Table 2 shows temperature difference for given air change rate obtained from above equation. With air change rate of about one, one can expect the inside temperature to be within two degrees of the outside. We selected to achieve an air change of one per minute or 360m3/min in the Kothara facility. So now we need to determine the total area and location of vents. Vents will have screens and there will be crop inside during operation.

Table 2: Air Change Rate and Temperature Difference

|

Delta T (°C) |

Air change rate |

|

1 |

2.1 |

|

2 |

1.1 |

|

3 |

0.8 |

|

4 |

0.7 |

Location of Vents

Two openings placed on opposite sides increase the air flow rate; also some vertical distance between openings is needed for flow to be caused by thermal gradient (ASHRAE Fundamentals 1985). Sides and roof configuration has been commended by Feuilloley et al.[3], Short was adopted. It was decided to have three vents - two opposite each other on the sides at the same level and one on the ridge (roof). The side vents are continuous and ridge vent is framed in segments. As all three vents are manually closable, this configuration would permit flexibility in operation.

Size of Openings

The peak wind speeds in the summer period (i.e March to June) was 8 to 10 m/s in Kothara area. We were taken 4m/s (half of the peak) for determination of the vent size. Using the wind coefficients given by Papadak[10] was the height of vent opening (length taken equal to the length of the side or ridge-20m) for the configuration –one on side and one on roof opposite- was found to be 0.53m (each). This will have a ventilation rate of one. As it was selected to have three vents, all were made equal of 20m X 0.5m. Total vent area amounts to 25% of the floor area -17% on the sides, 8% on the ridge. Vents were screened. There is provision for retractable shading cover over the roof made of non-woven shade -nets with 50% shading. Coefficients for the three vent configuration – two on side one on roof- were not found in literature. Also at the time when the facility was built, wind-related coefficients were not readily available for screened vents. Therefore it was not possible to determine, a priori, exact rate of ventilation that would actually result. Visual observations were made of the flow of smoke out of the greenhouse. Smoke was generated at three points in the closed and empty greenhouse. In one test all three vents were simultaneously opened. The wind direction at the time was south-west. Most of the smoke went out of the vent at the bottom on the north side. A much smaller amount exited through the top vent. House became apparently clear of smoke in just a few minutes.

Earth Tube Heat Exchanger

Procedure to design or select a fan-pad system for greenhouse of given size at any given location is well established along with the prescribed standards for components. This is not the case with the ETHE based systems. In computing the ventilation requirement of the greenhouse (air changes per hour) it was assumed that the greenhouse has crop canopy (not empty) and is kept shaded at peak times. The ETHE actually in place provides 20 air changes in the greenhouse per hour. Computations had shown that a higher ventilation rate is desirable, but the system was tending to become unwieldy, and expensive. It was therefore decided to limit the size to twenty air changes, and provide foggers to augment cooling at peak times. Air is moved by a centrifugal blower powered by a 4 KW, 1440 rpm motor.

ETHE is made of eight pipes arranged in two tiers. The first tier has four pipes placed at 3m depth and the second tier also has four pipes and is placed 1m above the first tier. Each pipe is 23m long and 20cm diameter. Pipes are made of mild steel, with 3mm wall thickness. Such pipes are commonly used as tube-well casing. Pipes are set 1.5m apart. There is a common header at both ends of each tier. Air is drawn from the greenhouse, cycled through the buried pipes and returned to the greenhouse. There are 39 foggers having discharge of 7lph and operating pressure of 4kg/cm2.

Fertigation Unit

There is a fertigation unit and dripper lines for watering and application of fertilizers.

Instrumentation to monitor Environment Parameters

An eight-channel data logger powered by chargeable 12 V battery was installed near system. Air temperature, relative humidity and wind speed (three cups anemometer at 5m above the ground) were measured and recorded on site every hour by a data logger (Weather Technologies India). Temperature measurements accuracy is ± 0.2 °C (resolution± 0.1°C), relative humidity accuracy is ± 3 % (resolution ± 0.1%), wind speed accuracy is better than ± 0.5 m/s with a stalling speed of 0.3m/s. Three weather shielded temperature sensors are placed 1m above ground at three locations on the centre line - ends and middle. Of the two soil temperature sensors, one is placed at 30 cm depth and the other just below the surface. Relative humidity sensor is placed over the centre line at the middle 1 m above ground. Data logger has LCD display, real time clock calendar, and serial output port for connecting it to PC with parallel interface to printer or memory module.

Results and Discussions

Environmental Control in Greenhouse

Natural ventilation with crop inside (tomato 1.9m high trellis supported) and top-shaded closed greenhouse in June showed a peak gain of 9.8°C (Table 3). It reduced to 3.1°C when all vents were opened. It is not expected that these results will be identical to those at other locations. But it is interesting to compare these with results reported by Tietel and Tanny[17]. They studied transient behavior of greenhouse located in the south of Israel (31.28 N, 34.38 E, 75m a.m.s.l.). The facility was four-span saw tooth structure with 960m2 floor and continuous roof windows of 67m2 total area i.e 6.9% of the floor. It had pepper trailed to a height of 2.8m during the tests. After several days of testing (up to 1 July) greenhouse allowed to heat up for an hour after being closed and it was hotter by 6.3°C from the ambient at 32.5°C at 10 am. When the roof vents were opened, the house began to cool and reached steady state in about 38 minutes. By then the house had cooled to just 1.2°C above the ambient which had remained nearly constant (about 31°C). During the test, the radiation level was closely around 872W/m2 and the wind was 2.5m/s. Tests were repeated over several days with similar results.

Table 3: Temperature Gain (crop inside greenhouse shaded till June 2005)

|

Status of Vents and Cooling System |

Temp. Gain in June 2005 2 pm(°C) |

Water used if foggers on (liter/hr) |

|

All vents closed |

9.8 |

off |

|

All vents open |

3.1 |

off |

|

All vents closed (ETHE turned on at10 AM turned off 4 PM) |

2.5 |

off |

|

All vents closed (ETHE on from 10 AM to 4PM, Fogger 30 min Off, 2 min On) |

1.2 |

18 |

|

Note: Tests done from June 16 to 22; solar radiation and wind speed sensors were malfunctioning. On days just before tests mean radiation levels between 10am and 4 pm was 883 w/m2 and mean wind speeds 8 m/s. |

||

Operation of ETHE

When ETHE system is operated (all the vents were closed), ETHE alone is able to limit the gain to 2.5°C. When ETHE system along with the fogging is also done (2 minute bursts every half hour) the gain is reduced further to just 1.2°C. Increasing the frequency of fogging further was tried but it did not help appreciably. The table also shows the amount of water lost in providing supplementary evaporative cooling 18 liters per hour at two bursts of 120s each per hour. ETHE provides for 0.33 air change per minute. The air change rate from the three vents was expected to be near one if there was no screen and no crop inside. Screens reduce the flow rate significantly (Table 1). Presence of tall crop reduces it further. Feuilloley, et al.[3] investigated the effect of vent size, location wind speed and height of vegetation on ventilation rates and reduction in temperature achieved in experimental Quonset tunnel. They reported “the best ventilation system has top and bottom openings and bottom opening area greater than top opening area. The optimal total opening area for this system is 32% (15% top, 17% bottom)”. They measured the ventilation coefficient (air change rate per hour) using (CO2) gas tracer technique. Opening area of 32% achieved with ventilation coefficient of 76 on bare ground and 40 with 1.8 m high ‘vegetation’. Effect of plant height on ventilation coefficient was simulated by erecting plastic windbreaks inside the tunnel. It is plausible that with tall crop inside and screened vents the three-vent configuration at Kothara provides air change rate of less than one. The ETHE forces the air mechanically and its output is not influenced by the crop. Thus the closeness of performance may be reasonable.

Heating by ETHE

Night temperature in Kothara generally begins to drop below 18°C in December. January nights are colder with temperature going down to 8°C to 9°C. Night temperature rises above 18°C by about middle of February. The temperatures in closed greenhouse at night were observed to be virtually the same as the ambient. Heating is therefore needed from December 15 to about February 15. It has been reported that heating is very effectively done with ETHE[12]. When temperature falls below 15°C inside the house, ETHE is turned on. It raises the temperature to 22-23°C within 30 minutes. An On/Off schedule can be adopted - turning it on when temperature reached about 15°C, off when it is raised to 22°C. It usually took 70 to 80 minutes for temperature to fall back again below 15°C.

Schedule of Environmental Control

In colder months (November to January and part of February) simply opening the vents for two hours around noon is adequate. Heating is needed at night which can be easily done by ETHE. Beginning February, top is shaded and vents are opened for four hours around noon. This procedure keeps the inside temperature below 34°C. In beginning of April month, ETHE is operated and on occasionally fogging is also used. This procedure keeps the inside temperature about 34° C -36°C. Cropping was continued till middle of May. Greenhouse was closed from May 15 to June 30. Cropping is resumed in July.

Tomato Cultivation in Greenhouse

A cropping trial of hybrid tomato (cv Avinash F2 of Sygenta) was grown which is more common among the commercial growers (Figure 2). Seedlings were planted on October 28, 2004 (Table 4). The last picking was on May 15, 2005. The crop was maintained in the greenhouse till the third week of June (only for tests and other observations). April onwards the produce was getting better price because March onwards there is no standing crop of tomato anywhere in the whole province. But by the end of May fruit size reduced, quantity picked per week also reduced and it became too hot. We can able to carry out cropping well into the summer is a very important achievement in this hot and arid area.

|

|

Table 4: Summary of Cropping Trials in Arid Area Greenhouse

|

Sr. No. |

Details |

Tomato |

|

1. |

Variety |

Avinash F2 hybrid |

|

2. |

Plant spacing |

45 x 45 cm. |

|

Planted area |

95 m2 |

|

|

3. |

Planting date |

28 October, 2004 |

|

First flowered |

30 days after planting |

|

|

First picking |

February 16 (100 days after planting |

|

|

Last picking |

May 15 2005 ( 195 days after ) |

|

|

4. |

Fruit size |

Major axis 5.5 – 6.0 cm |

|

Minor 5.2 – 5.8 cm |

||

|

5. |

Plant height |

190.0 cm |

|

6. |

Yield |

56.3 t/ha |

|

7. |

Total fogger water applied |

0 |

Economy in use of Water

Total irrigation water applied was 211 mm. This is only about half of that used in the open-field cultivation of tomato (It was stated earlier that yields was less and the season ends in March). Although in the course of the first trial foggers were occasionally used, during this cropping trial foggers were not used. The reason for not using the foggers was that particles of water that landed on leaves appeared to cause tiny dull brown spots looking like salt-burn injury.

Increase in Yield per Round of Cropping

Total yield was an equivalent of 56.3 t/ha. In immediate neighborhood in this district itself the best yield in open-fields is reported by growers to be just 15 t/ha. In other parts of this province however, which are humid, the best yield reported is 30 t/ha. Thus the AAG yield is nearly two times that of the best open -field yields in humid areas of the province.

Conclusion

Greenhouse technology with suitable adaptation can be used in hot, arid areas to improve yields, extend cropping season and make better use of scarce water. Earth-tube-heat-exchanger and static ventilation are the two promising adaptations which can be used for environmental control. ETHE also provides an effective means of heating in winter nights. The facility with these features is termed Arid Area Greenhouse. AAG at Kothara had static vent area equivalent to 25% of the floor area (the two side vents accounted for 17% and the ridge vent for 8%). The ETHE has capacity to provide twenty air changes per hour. It is embedded in the strata between 2 to 3 m below the greenhouse where mean temperatures are 27°C with small annual amplitude of fluctuation.

- Opening the vents from 11 A.M. to 4 P.M. and shading from top was adequate to keep the house below 34°C till the middle of January. Subsequently, ETHE needed to be operated. ETHE operation limited the temperature gain and kept the inside temperature nearby 36°C.

- Water required to raise a crop of hybrid tomato was nearly half of that required in the open field in Gujarat. Yield was nearly two times that of the open field conditions of this province.

References

- Boulard, T., and Baille, A. Modelling of air Exchange Rate in a Greenhouse Equipped with Continuous Roof Vents. Journal of Agriculture Engineering Research, 61: 37-48 (1995).

CrossRef - Boulard, T., and Draoui, B. Natural Ventilation of a Greenhouse with Continuous Roof Vents: Measurements and Data Analysis. Journal of Agriculture Engineering Research, 61: 27-36 (1995).

CrossRef - Feuilloley, P., Mekikdjian, C., and Gratraud, J. Optimal static ventilation in greenhouses. In: Proceedings of XI International Congress: The Use of Plastics in Agriculture. Oxford and IBH Publishing Company Private Limited, New Delhi, India (1990).

- Kacira, M., Short, T. H., and Stowell, R. R. A CFD Evaluation of Naturally Ventilated, Multi-span, Sawtooth Greenhouses. Trans of ASAE, 41(3): 833-836 (1998).

CrossRef - Kittas, C., Boulard, T., Bartzanas, T., Katsoulas, N., and Mermier, M. Influence of an Insect Screen on Greenhouse Ventilation. American Society of Agricultural Engineers, 45(4): 1083-1090 (2002).

CrossRef - Kittas, C., Boulard, T., Mermier, M., and Papadakis, G. Wind Induced Air Exchange Rates in a Greenhouse tunnel with Continuous Side Openings. Journal of Agriculture Engineering Research, 65: 37-49 (1996).

- Mears, D. R. Opportunities for collaborative Indo-US greenhouse research. In: Proceedings of XI International Congress: The Use of Plastics in Agriculture. Oxford and IBH Publishing Company Private Limited, New Delhi, India (1990).

- Miguel, A. F., Van de Braak, N. J., and Bot, G. P. A. Analysis of the Airflow Characteristics of Greenhouse Screening Materials. Journal of Agriculture Engineering Research, 67: 105-112 (1997).

CrossRef - Muñoz, P., Montero, J. I., Antón, A., and Gifford, F. Effect of Insect-proof Screens and Roof Openings on Greenhouse Ventilation. Journal of Agriculture Engineering Research, 73: 171-178 (1999).

CrossRef - Papadais, G., Mermier, M., Meneses, J. F., and Boulard, T. Measurement and Analysis of Air Exchange Rates in a Greenhouse with Continuous Roof and Side Openings. Journal of Agriculture Engineering Research, 63: 219-228 (1996).

CrossRef - Santamouris, M., Mihalakaha, G., Balaras, C. A., Argirioua, A. D., and Vallinaras, M. Use of Buried pipes for energy conservation in cooling of agricultural greenhouse. Solar Energy, 35: 111-124 (1995).

CrossRef - Sharan, G., Prakash, H., and Jadhav, R. Performance of Greenhouse Coupled to Earth Tube Heat Exchanger in Closed-Loop Mode. XXX CIOSTA-CIGR V Congress Proceedings of Management and Technology Applications to Empower Agriculture and Agro-food Systems, Turin, Italy, Vol.2: September 22-24, 865-873 (2003).

- Sharan, G., and Jadav, R. A Performance of Single Pass Earth Tube Heat Exchanger: An Experimental Study. Journal of Agricultural Engineering, 40(1): January-March, 1-8 (2003).

- Sharan, G., and Jadhav, R. Soil Temperature Regime at Ahmedabad. Journal of Agricultural Engineering, 39(1): January-March (2002).

- Sharan, G., and Madhavan, T. Simulation of Performance of Earth Tube Heat Exchanger using a Mathematical Model. Journal of Agricultural Engineering, 40(3): July-September, 8-15 (2003).

- Sharan G; Sahu R K; and Jadhav R. Earth Tube Heat Exchanger Based Air-conditioning for Tiger Dwellings. Zoos' Print, 16(5): May (2001).

- Tietel, M., and Tanny, J. Natural Ventilation of Greenhouses: Experiments and Model. Agricultural and Forest Meteorology, 96: 59-70 (1999).

CrossRef