The Effect of Silica Fume on the Properties of Self-Compacted Light weight Concrete

Yaghuob Mohammadi1 * , Seyyed Sajjad Mousavi1 , Farnam Rostami2 , Akbar Danesh3 and Nasim Irani Sarand1

1

Department of Civil Engineering,

Mohagheghe Ardabili University,

Ardabil,

Iran

2

Department of Civil Engineering,

University of Tehran,

Tehran,

Iran

DOI: http://dx.doi.org/10.12944/CWE.10.Special-Issue1.48

This paper is aimed to study the effect of silica fume on properties of self-compacting lightweight concrete (SCLC) containing perlite and leca. For this purpose, silica fume has been replaced by different contents. In this study, all mixtures total cementitious materials (cement + silica fume) were kept at 450 kg/m3. Additionally, workability of SCLC mixtures was assessed by means of Slum flow, L-box, U-box, V-funnel and J-ring. This research shows that mixtures without silica fume were not satisfactory. Besides, bleeding and segregation of this mixture were observed. For all tests added the silica fume demonstrated acceptable values. However, for the SCLC mixture containing 15% silica fume significant results were attained.

Copy the following to cite this article:

Mohammadi Y, Mousavi S. S, Rostami F, Danesh A, Sarand N. I. The Effect of Silica Fume on the Properties of Self-Compacted Light weight Concrete. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). DOI:http://dx.doi.org/10.12944/CWE.10.Special-Issue1.48

Copy the following to cite this URL:

Mohammadi Y, Mousavi S. S, Rostami F, Danesh A, Sarand N. I. The Effect of Silica Fume on the Properties of Self-Compacted Light weight Concrete. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). Available from: http://www.cwejournal.org

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2014-11-19 |

|---|---|

| Accepted: | 2014-11-30 |

Introduction

Self-compacted concrete (SCC) was first developed by H. Okamura in Japan in 1986. SCC can save labor, eliminate consolidation noise and has an excellent filling and produce high quality concrete structure. Using lightweight aggregates in the concrete mixture, show significant reduction in the self-weight of structure, which result in reduced member's section (Okamura et al., 1996), (Ergul et al., 2003).

The developments in the construction industry and the advantages of the SCC, has leaded to many studies on these types of concretes.

Karahan et al, studied the effect of metakaolin content on the properties of self-compacted lightweight concrete. Absorption and porosity results showed a slight decrease in porosity and water absorption values with the increase of metakaolin content and also, increase in metakaolin content showed significant effects on chloride ion penetration resistance of self-compacted lightweight concrete (Karahan et al., 2012).

Mazaheripour et al, investigated the effect of polypropylene fibers on the properties of the fresh and hardened self-compacted lightweight concrete. The presence of polypropylene fibers in leca self-compacted lightweight concrete greatly decrease the slump flow and do not have an influence on the compressive strength and elastic module of LSCLCs (Mazaheripour et al., 2011).

Madandust et al, researched the fresh properties of self-compacted lightweight concrete containing expanded polystyrene (EPS). The results showed that the segregation tendency of EPS aggregates can be decreased by applying nano-sio2 (Madandoust et al., 2011).

The main objective of this study was to study the effect of silica fume on properties of self-compacting lightweight concrete (SCLC) containing perlite and leca. For this purpose, workability and passing ability of SCLC mixtures were assessed by means of Slum flow, L-box, U-box, V-funnel and J-ring. Additionally compressive strength of mixtures examined as mechanical properties of SCLC which illustrated in next sections.

Materials and Mixtures Properties

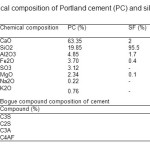

The Portland cement used in this investigation was delivered from Ardabil with the density of 3130 Kg/m3 and the used silica fume was produced at Namikaran factory. The chemical properties of cement are presented in table 1.

|

Table 1: Chemical composition of Portland cement (PC) and silica fume (SF) Click here to View table |

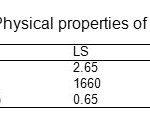

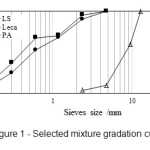

The mixtures of SCC containing two different aggregates, perlite and leca, in order to investigate the effects of aggregates type on the physical and mechanical properties of SCC. The natural sand was replaced with lightweight aggregates in the SCC mixture and also used crushed lime-stone (LS) as a coarse aggregate. The physical properties of the aggregate are presented in Table 2 and their gradation curve is shown in Fig 1.

|

Table 2: Physical properties of aggregates Click here to View table |

|

Figure 1: Selected mixture gradation curve Click here to View figure |

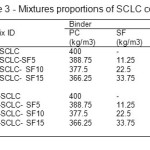

A total of eight SCLC mixtures were tested in this research. In all mixtures the amount of super plasticizer was 2% and the water/cementitious ratio (w/c) was 0.5. The mixtures contained 0%, 5%, 10% and 15% silica fume as a cement replacement. To prepare concrete mixture, half of natural coarse and fine aggregates were poured into the rotating concrete mixer and after 30 s mixing, cement and remaining aggregates and 50% of water homogenized 1min at normal mixing speed. Thereafter, half of water and super plasticizer added to the mixture and mixed for 5min.

The specimen of concrete test has been manufactured without compacting. The compressive strength was obtained for a cube of 100 × 100 × 100 mm in dimension. Specimens were demolded 1 day after casting and then cured in water at approximately 20 °C until testing was carried out at 3, 7, 28 and 90 days’ age. Three specimens of each mixture were tested and the mean value was reported.

|

Table 3: Mixtures proportions of SCLC concrete Click here to View table |

Results and Discussion

Properties of Fresh Concrete

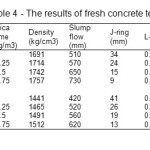

Tests results of leca self-compacted lightweight concrete (L-SCLC) and perlite self-compacted lightweight concrete (P-SCLC) are summarized in table 4.

|

Table 4: The results of fresh concrete testes Click here to View table |

Respect to table 4, for mixtures without SF, it can be seen that the slump flow values were not in good range. However, L-SCLC showed better results than P-SCLC due to uniform mixture which promote the packing of particles and decreasing the free water. The results of the J-Ring tests were not in the allowable range and the observed slump values were less than slump flow tests. The L-Box test was used to determine passing ability of SCC through reinforced area. The ratio of the height of concrete remaining at the leading edge in the horizontal section to that in the vertical section is a good indicator of the passing ability (Madandoust et al., 2011).

The obtained values, 0.56 for leca and 0.43 for perlite, are demonstrated weak passing ability. The V-Funnel test was also used to describe the stability of SCC as well as viscosity assessments. The time takes by fresh concrete to flow out of the funnel was measured and recorded as the V-Funnel time (Madandoust et al., 2011).

On the basis of EFNARC Committee, the V-Funnel time ranges between 6 to 12 s. However, the results were not in this range. The last test was the U-Box test, which used to assess the filling ability of self-compacted lightweight concrete. The results presented that self-compacting property of the mixtures were not acceptable and could be improved by appropriate additives. The segregation problem could be solved by increasing the paste volume and flowability, so silica fume was used.

According to table 4, flowability and segregation resistance improved by adding 5% SF to the mixtures but the required flowability for the slump test was not achieved. The V-Funnel time was in allowable range. The results of the U-Box tests were improved but the results of the J-Ring and the L-Box tests indicated low passing ability. However, the result of P-SCLC-SF5 mixture was in acceptable range. When the percentage of silica fume was increased from 5% to 10%, the results became better. For the P-SCLC-SF10 mixture the slump flow was 56 cm which meant better flowability. But it is not in allowable range of EFNARC. For the L-SCLC mixture the ratio of 0.88 resulted from the L-Box test indicated good passing ability. The results of U-Box test were higher than allowable range.

When the percentage of silica fume was 15%, the properties of a good self-compacted concrete were prepared. For L-SCLC-SF15 mixture the slump flow was obtained 73cm and the results of J-Ring test indicated considerable flowability. The 0.93 ratio for the L-Box test meant good passing ability of the concrete. In general, the L-SCLC mixtures had better results than the P-SCLC mixtures. The results and allowable range for self-compacted concrete according to EFNARC are shown in figure 2-6.

|

Figure 2: Slump flow test results Click here to View figure |

|

Figure 3: J-ring test results Click here to View figure |

|

Figure 4: L-box test results Click here to View figure |

|

Figure 5: V-funnel test results Click here to View figure |

|

Figure 6: U-box test results Click here to View figure |

Properties of Hardened Concrete

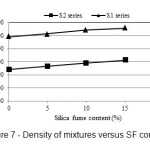

According to table 4, all the mixtures' densities are less than 1800 Kg/cm3 and for the series S2 mixtures, the maximum density is 1512 Kg/cm3. The effects of silica fume percentage on the mixtures' density are presented in figure 7. By increasing the percentage of silica fume, the density increase.

|

Figure 7: Density of mixtures versus SF content Click here to View figure |

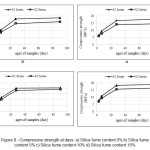

Compressive strength test results for silica fume content self-compacted concrete for 3, 7, 28 and 90 day old samples are shown in figure 8. The minimum compressive strength was related to 3 day old sample and the maximum compressive strength was related to 90 day old sample.

|

Figure 8: Compressive strength at days: a) Silica fume content 0% b) Silica fume content 5% c) Silica fume content 10% d) Silica fume content 15% Click here to View figure |

The compressive strength of 3 day old sample obtained for two mix series were almost the same with very small difference. As the age of samples increase, the difference of compressive strength between two samples increases. However, by increasing the content of silica fume these differences became lower and the types of lightweight aggregates did not have significant effect especially for 90 day samples. The maximum difference is related to 28 day old sample. In addition, according to the figure, it is concluded that, silica fume increase the compressive strength of sample.

Despite the effect of SF on the compressive strength for samples containing perlite is more than the samples with leca content, the compressive strength of samples containing leca are larger in the all cases. For instance, the compressive strength of 90-day old leca content samples were 17.96, 18.64, 19.15, 20.29 MPa for mixtures containing silica fume whit 0, 5, 10, 15%, respectively. These values were 22.5, 16.7, 15.7 and 7.1 percent larger than samples containing perlite. This means that by increase in SF percent, the obtained results are less depended to the aggregates types.

Conclusion

Based on the results presented in this paper, the following conclusion can be drawn:

- Compressive strength of concrete mixtures containing Leca was larger than mixtures containing Perlite.

- As the percentage of silica fume was increased from 5% to 15%, the results became better for two L-SCLC and P-SCLC samples.

- By adding silica fume, compressive strength of samples increased. The maximum increase were related to mixtures number 4 and 8.

- The best design mixture was related to mixture number 4 which had the maximum compressive strength.

- As the additive content increases, the density of sample increases.

- The densities of L-SCLC samples are higher than P-SCLC samples, because the density of leca is higher than perlite.

References

- Okamura, H. and Ozawa, K. Self-Compacting High Performance Concrete. Structural Engineering International, 6(4),269-270 (1996)

- Ergul, Y. Cengiz, D.A. Alaettin, K, Hasan, G. Strength properties of lightweight concrete made with basaltic pumice and fly ash. Materials Letters, 57(15),2267– 2270 (2003)

- Karahan, O. Hossain, K.M.A, Ozbay, E. Lachemi, M. Sancak, E. Effect of metakaolin content on the properties self-consolidating lightweight concrete. Construction and Building Materials, 31,320–325 (2012)

- Mazaheripour, H. Ghanbarpour, S. Mirmoradi, S.H. Hosseinpour, I. The effect of polypropylene fibers on the properties of fresh and hardened lightweight self-compacting concrete. Construction and Building Materials, 25(1),351–358 (2011)

- Madandoust, R. Ranjbar, M.M.S. Mousavi, Y. An investigation on the fresh properties of self-compacted lightweight concrete containing expanded polystyrene. Construction and Building Materials, 25(9),3721–3731 (2011)

- EFNARC, S., guidelines for self-compacting concrete. Free pdf copy downloadable from http://www. efnarc. org, 29-35 (2002)