Study on Application Potential of Waste Cake from Secondary Zinc Industry

Mohd Akram Khan1 * and Rajnish Shrivastava2

1

Principal Scientist, CSIR-AMPRI,

Hoshangabad Road,

Bhopal,

India

2

Director, National Institute of Technology (NIT),

Hamirpur,

India

DOI: http://dx.doi.org/10.12944/CWE.7.1.09

Zinc extraction process generates hazardous waste cake during the recovery of electrolytic grade zinc and copper. The characteristics of the waste with reference to basic properties viz. ignitability, corrosivity, reactivity and EP toxicity are important parameters that define the magnitude of hazard of a waste. The waste under study falls under Schedule-I of Hazardous Waste (Management & Handling) Rules, 2003. The Toxicity Characteristics Leachate Procedure (TCLP) test was carried out for extraction of waste cake leachate and subsequently toxic heavy metals present in the waste were estimated. The physic-chemical parameters along with particle size analysis, differential thermal analysis and X-ray diffraction analysis were carried out which provide information on the major constituents present in the hazardous zinc waste cake before and after stabilisation/stabilisation of the waste. The approach would be helpful in safe disposal and exploring application potential of zinc waste through adoption of suitable binder mechanism.

Copy the following to cite this article:

Khan MA, Shrivastava R. Study on Application Potential of WasteCake from Secondary Zinc Industry. Curr World Environ 2012;7(1):51-54 DOI:http://dx.doi.org/10.12944/CWE.7.1.09

Copy the following to cite this URL:

Khan MA, Shrivastava R. Study on Application Potential of WasteCake from Secondary Zinc Industry. Curr World Environ 2012;7(1):51-54. Available from: http://www.cwejournal.org/?p=1801

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2012-04-25 |

|---|---|

| Accepted: | 2012-06-07 |

Introduction

The rapid industrialisation has lead to severe environmental threats through generation of large quantities of industrial wastes and hazardous sludges. The primary sources of hazardous wastes in India and other developing countries include waste generated within the country through different industrial units and waste imported into the country as raw materials. A study carried out on solid waste management in non-ferrous industries in India mentions alarming levels of hazardous secondary zinc wastes and other industrial wastes that are threatening the environment.1

Hazardous waste means a solid waste or a combination of solid waste which by virtue of its quality, concentration or physical or chemical or infectious character may cause to an increase in mortality or serious illness or pose a potential hazard to human health or the environment when improperly treated, stored, transported or disposed.2 India has witnessed nearly fivefold increase in its industrial production in the last few decades and presently more than 500 medium and large chemical and allied industries are in operation.3 The present study covers the industrial waste generated by secondary zinc industry located in the western part of India and generates around 5,000 TPA of the waste cake.

It is well known that production of pesticides and herbicides used in agricultural application produce wastes of hazardous / toxic nature. Similarly fluoride waste and by-products of phosphate fertilizer industry also generate hazardous toxic wastes. Household sources of hazardous waste include metallurgical scraps, secondary industry process waste cake, toxic paints, solvents, caustic cleaners, batteries, drugs etc. These wastes contaminate the soil and ground water and adversely affect the natural eco-system through percolation of heavy metals into the soil and natural water sources.3

The release of harmful chemicals / toxic wastes into the environment mainly through industrial, agricultural, household and transport route results in air, soil and water pollution. Major man made sources of pollutants are linked to mining and metal production, metal extraction, fossil fuel burning, coal mining, production of conventional building materials, chemical and pharmaceuticals, use of chemical fertilizers, municipal and industrial waste dumps, incinerators and other specialised dumping sites.4 The locations particularly threatened are areas which are already environmentally overloaded and have no free absorption capacity areas with shallow ground water and porous soil regions.

The manufacturing of different computer components involve many industrial processes which lead to generation of liquid wastes. A printed circuit board generates spent electroplating bath that contains metal salts and the production of the computer chips use acids, caustic chemicals and solvents. Hazardous waste is also generated by fiber optics and copper wire used in electronic transmission as well as magnetic disks, paper and photographs for packaging and publicity.

The concepts relating to hazardous waste management emerging day by day and undergoing review and upgradation in India. The Government of India has promulgated the Hazardous Waste (Management & Handling) Rules, 1989 through MoEF, New Delhi under the aegis of Environmental Protection Act, 1986. The rules were modified through an amendment as Hazardous Waste (M&H) Amendment Rules, 2002. Based on the further suggestions received and considering the various new methodologies, Govt. of India notified Hazardous Waste (Management & Handling) Rules, 2003 and suggested modifications in Schedule-I with the list of processes generating hazardous wastes. It also mentions the secondary production and / or use of zinc generating sludge and filter press cake, zinc fines / dust / skimming in the list.5

Classification of Hazardous Waste

Characterisation and classification of hazardous waste is required for safety reasons to ensure that incompatible wastes are identified and handled separately. Wastes can be classified by using relatively simple and inexpensive test methods during waste collection and laboratory analysis. There are four main characteristics namely ignitability, corrosivity, reactivity and Extraction Potential (EP) toxicity which determine whether a waste is classified as hazardous waste or not [5]. They have been elaborated below:

Ignitability

Solid waste exhibits the characteristics of ignitability if a representative sample of that waste is a liquid containing less than 50% water and less than 24% alcohol and the flash point is less than 60 oC.

Corrosivity

Solid waste exhibits the characteristics of corrrosivity if a representative sample of waste is aqueous and has pH less than or equal to 2 or greater than or equal to 12.5 or liquid and corrodes steel at a rate greater than 6.35mm (0.25 inch) per day under a temperature of 55oC.

Reactivity

Reactive wastes are those that are extremely unstable under normal conditions with tendency to explode or give off dangerous gases. Standard methods to test reactivity currently do not exist and it is possible only to list their physical peculiarities. A solid exhibits the characteristics of reactivity if a representative sample of the waste is typically unstable and readily undergoes violent changes without deteriorating, reacts violently with water and forms potentially explosive mixture with water.

EP Toxicity

The EP toxicity is the measure of the likelihood that waste will leach out toxic chemicals. A particular waste is considered toxic if concentrations of any of the heavy metals in its extract are greater than standards mentioned as per the permissible limits of Hazardous Waste (M & H) Rules, 2003.5

Materials and Methods

TCLP test was adopted in 1968 by the US Environment Protection Agency (USEPA) as a replacement of EP toxicity. The TCLP is also widely used to evaluate the effectiveness of stabilisation of the waste. In this test method, the waste material is crushed to a particle size smaller than 9.5 mm and mixed with a weak acetic acid as extraction liquid (pH 4.93) in a liquid to solid weight ratio of 20:1 and agitated in a rotary extractor for a period of 18 hours at the speed of 30 rpm and 22 oC.6 The sample is filtered through 0.6-0.8 µm glass fiber filter paper and the filtrate is defined as the TCLP extract. This extract is analysed for wide variety of hazardous waste constituents including heavy metals of interest in the waste.

Results and Discussion

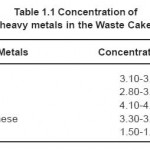

The secondary zinc waste cake is neutral in nature with its pH around 6.3 and particle density to be around 2.4 gm/cc. The moisture content varied in the range of 24 to 35%. The waste cake mainly consists of zinc, copper, manganese, lead and iron as predominant heavy metals present in the sample.

Particle Size Analysis

The hazardous waste collected from the rotary vacuum filter (waste cake) was dried and particle size analysis was carried using standard sieves and using Laser Particle Size Analyser (Malvern make). The results show that the waste sample consists of clay sized particles upto 20% and silt size particles upto 52% of the total weight.

X-Ray Diffraction Analysis

X-Ray Diffraction Analysis was carried out by Philips Diffractometer model 1710 using CuK radiation and nickel filter at 40kV and 20mA. The identification of mineral phases was done with the help of mineral powder diffraction file JCPDS and ASTM diffraction data. The major peaks identified in the waste sample are that of Gypsum with Mn2O3 and lime in traces.

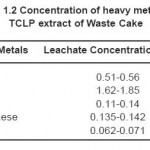

TCLP Testing

Leachability test was carried out by using Millipore make Zero Headspace Extractor (ZHE). The sample is agitated for 18 hours in a rotary agitator for extracting the secondary leachate. The primary and secondary extracts were obtained at 50 psi pressure with glacial acetic acid and NaOH solution as extraction fluid at a pH of 4.93.6 The leachate obtained is analysed for different heavy metals using Hitachi make Atomic Absorption Spectrophotometer. The analysis results for the waste sample are as below:

Solidification is the process by which the sufficient quantities of solidifying materials are added to the hazardous waste to result in a solidified and encapsulated mass of materials. Stabilisation is a process that uses additives to reduce the hazardous nature of the waste by converting the waste and its hazardous constituents into a form to minimise the rate of contaminant migration in the environment and to reduce the level of toxicity. Many technologies have been proposed for detoxifying the waste by processes that destroy chemical bonds so that the toxic nature is minimised.

It is reported that approximately 0.5 million tonnes of lead-zinc slag is generated annually and this slag can be used upto the extent of 45% as blending component for the manufacture of Portland Slag Cement.7 This indicated that the waste cake has potential for its reuse in different applications.

|

Table 1.1: Concentration of heavy metals in the Waste Cake Click here to View table |

|

Table 1.2: Concentration of heavy metals in TCLP extract of Waste Cake Click here to View table |

The hazardous secondary zinc waste was found suitable for encapsulation with different binders like fly ash, clay and their combinations in defined proportion. The results indicated that leaching properties of heavy metals present in the waste cake got arrested in the solidified-stabilised mass thus converting them into non-hazardous form of waste.

Conclusion

The characteristics and categorisation of hazardous waste is one of the important aspects of the hazardous waste management. The secondary zinc extraction process produces waste cake that falls in Schedule-I of Hazardous Waste (M&H) Rules, 2003. The hazardous waste can be characterised by TCLP testing to identify the leachable toxic elements and can be solidified & stabilised by using different binder materials. The new material provides good alternative for safe utilisation and disposal of zinc waste cake.

Acknowledgements

The authors are extremely thankful to Director, CSIR-AMPRI Bhopal for the permission to carry out this work and for the facilities provided for the research work.

References

- Agrawal A., Sahu K.K., Pandey B.D., Solid waste management in non-ferrous industries in India, Resources Conservation & Recycling, 42: 99-120, Elsevier Publication (2004).

- LaGrega M.D., Buckingham P.L. and Evans J.C., Hazardous Waste Management, Mc-Graw Hill International Edition (1994).

- Toxic and hazardous waste disposal - An Indian perspective, Nag P.J., Chemical Industry News, 1027-1029 (1996).

- Stanley E. Manahan, Fundamentals of Environmental Chemistry, Second Edition, Lewis Publishers (2001).

- Hazardous Waste (Management & Handling) Rules, Ministry of Environment & Forests, Govt. Of India, notification dated 20th May 2003 (2003).

- Toxicity Characteristics Leachate Procedure, Millipore Information Booklet (2000).

- Assessment of Utilisation of Industrial Solid Wastes in Cement Manufacturing, Central Pollution Control Board Report, MoEF, New Delhi, (2006).

- S. Katanyoon, W. Naksata, P. Sooksamiti, S. Thiansem and Orn-Anong Arquero. Orient J. Chem. 28(1): 373-378 (2012).