Development of a Sustainable Dyeing Process for Cotton fabric Utilizing Natural Dyes from Punica granatum L. and Curcuma Longa

1

Department of Chemistry,

N.V.P. Mandals. Arts, Commerce and Science College,

,(Affiliated to Savitribai Phule Pune University),

Lasalgaon, Nashik,

Maharashtra

India

2

Abasaheb Garware College,

Karve Road,

Pune,

Maharashtra

India

3

Department of Chemistry,

K K W Arts, Science and Commerce College Pimpalgaon (B),

Nashik,

Maharashtra

India

Corresponding author Email: ahirebb07@rediffmail.com

DOI: http://dx.doi.org/10.12944/CWE.19.1.12

Copy the following to cite this article:

Ahire B. B, Kasabe S. M, Mali A. B, Jadhav R. B. Development of a Sustainable Dyeing Process for Cotton fabric Utilizing Natural Dyes from Punica granatum L. and Curcuma Longa. Curr World Environ 2024;19(1). DOI:http://dx.doi.org/10.12944/CWE.19.1.12

Copy the following to cite this URL:

Ahire B. B, Kasabe S. M, Mali A. B, Jadhav R. B. Development of a Sustainable Dyeing Process for Cotton fabric Utilizing Natural Dyes from Punica granatum L. and Curcuma Longa. Curr World Environ 2024;19(1).

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2023-12-18 |

|---|---|

| Accepted: | 2024-05-02 |

| Reviewed by: |

Rakhshan Ahsan

Rakhshan Ahsan

|

| Second Review by: |

Geetha Margret

Geetha Margret

|

| Final Approval by: | Dr. Hiren B. Soni |

Introduction

Natural colors offer vibrant dyes for cotton fabrics. These colors were obtained from minerals, plant parts, trees, and even soil, making them a sustainable and safe choice for various applications. Historically, natural colors have been used for centuries to color food, cosmetics, clothes, furniture, and artwork. From ancient remedies and dyes for cotton fabrics to modern food coloring and ayurvedic medicines, the versatility of natural colors is undeniable1, 2.Natural color dyes are often obtained from herbs, tree parts, and vegetables. Plants like greenish wattle bark, cocks comb flowers, ripe mango, tea leaves, pomegranate rinds all yield vibrant colors when extracted. Even curcumin, commonly found in turmeric, can be used as a natural dye. For added vibrancy and shine, natural dyes can be used with mordents, such as the peel of Allium cepa extract, which enhances the color's depth and stability3.With their rich history and sustainable nature, natural colors continue to be a popular choice for artists, designers, and those seeking eco-friendly alternatives. Their vibrant hues and diverse applications make them a valuable resource for a variety of disciplines, offering a colorful and harmonious way to connect with the natural world.Natural dyes offer a promising alternative to traditional dyes, particularly for environmentally conscious consumers and producers. Studies have demonstrated that natural dyes, like those derived from Allium cepa and metal mordants, can achieve excellent results on cotton fabrics4.

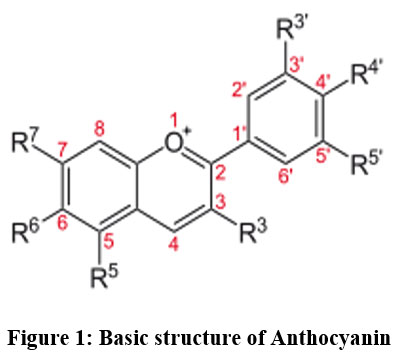

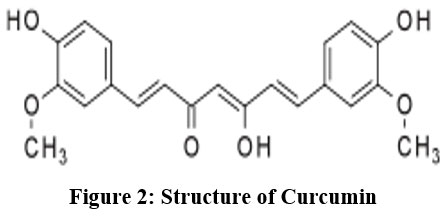

Natural dyes like neem extract have been successfully used for cotton dyeing5.Pomegranate, a member of the Punicacea family, it is 5-10 meter tall and thrives in temperate regions worldwide6,7. Its natural pigments, including flavonoids, minerals, and anthocyanins, contribute to its vibrant color and antioxidant properties8,9. Anthocyanins, like delfinidin-3,5-diglucoside and cyanin-3,5 diglucoside, play a key role in the color spectrum produced by pomegranate dyes. These natural dyes exhibit good dyeing properties and have the added benefit of being antioxidants.Another promising natural dye is turmeric, an herb belonging to the Zingiberaceae family. Its rhizomes contain curcumin, a compound responsible for its distinctive yellow color. This natural pigment offers the potential for vibrant and colorfast dyeing on cotton fabrics.The utilization of natural dyes like Allium cepa, neem extract, pomegranate, and turmeric presents an exciting opportunity for sustainable and eco-friendly textile production. Their potential for achieving excellent results on cotton and other fabrics, coupled with their inherent antioxidant properties, highlights the value of natural dyes in creating beautiful and environmentally responsible textiles.Maharashtra has gross cultivator of cotton crops in the country. Textile industries produce cotton fabric a lot. Cotton is commonly grown as natural fiber. It is hygroscopic, has comfortable heat conductivity and known as cellulose. Now, cotton cloths have no harm to the skin than a variety of synthetic cloths dyeing with synthetic dyes. Such fabrics are harmful, irritant, allergic and carcinogenic as well. It has been found that ten lakh tons of synthetic dyes were used per annum10. It produces waste and cause pollution problem. Cotton cloths are not harmful and are healthy, and comfortable for body wearing and various purposes.

Natural dyes are being sustainable11,12, biodegradable, compatibility,non-polluting, non-carcinogenic, easily available and ecofriendly in nature13,14,15 and pollution-free dyeing process16.Natural dyes may act as antimicrobial and antioxidant properties17. These do not cause any pollution18. A cobalt nitrate, Copper sulphate, ferrous sulphate, nickel chloride, and Potassium dichromate was used as mordents for dyeing 19, and metal salt are used as a mordant and with dyestuff fixes on the fiber.Due to greater affinity, the Mordant had bonded with specific dyes and fixed on fabric20, 21. Different metal ions as mordant acts as electron acceptor form donors to form coordinate bonds between them. Mortants are light-sensitive 22. However, natural dyes and the metallic Mordant for dyeing often puts a doubt about eco-friendliness 23- 27.An effluent produced after dyeing may lead to pollution problem. It should be solved by proper treatment of the effluent.Present innovation enables the use coloring natural extracts for dyeing cotton fabrics.

Material and methods

Analytical reagent (A.R.) grade chemicals, including CuSO4 (Copper sulfate), NiCl2 (Nickel chloride), FeSO4 (Ferrous sulfate), and K2Cr2O7(Potassium dichromate), were used directly as mordants.

Pure 100% cotton fabric (plant origin) was purchased from a local market. Before dye application, the fabric was bleached for optimal results.Fresh pomegranate fruits and curcuma longa (turmeric) rhizomes were sourced from the Lasalgaon region in Maharashtra, India, for natural dye extraction.Selected pomegranate fruit grains were utilized as the Punica granatum (pomegranate) source for traditional dye extraction.

For mordanting the cotton fabric, chemical reagents such as nickel chloride (NiCl2), copper sulfate (CuSO4), potassium dichromate (K2Cr2O7), and ferrous sulfate (FeSO4) salts were employed. The shade of the fabrics intensity was controlled by varying duration of cotton fabric immersion in a dye bath. Lighter shades were achieved by keeping the fabric in the bath for a shorter period, while deeper shades were obtained by leaving the fabric overnight. The open bath exhaust process was chosen as the preferred dyeing technique in this study. This method involves immersing the fabric directly in a dye bath and allows the dye to gradually exhaust onto fibers.

Dye Extraction and Fabric Preparation

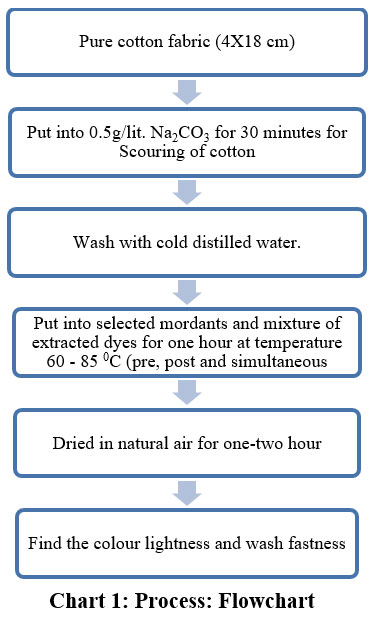

For pomegranate dye extraction, 200 grams of Punica granatum fruit grains were collected and juiced with small amount of pure water. The juice solution was clarify and made it to concentrate. Turmeric powder was prepared by grinding dried Curcuma Longa rhizomes in a powdered form. To extract the dye,it was submerged in deionized water to specific temperature for one hour. The resulting extract, with a clear yellowish color, was then collected.Both extracts were thoroughly mixed to create the final dye mixture used for cotton dyeing 28.Prior to dyeing, the cotton fabric underwent a scouring process to remove impurities and enhance dye uptake. This was achieved by bleaching the fabric with a solution of 0.5 g/liter sodium carbonate and at a 50 – 60°C temperature for one hour. The scoured cotton was then dried naturally, ensuring it was clean and ready topass for dyeing process 29.

Experimental Techniques

This research employed three different mordanting techniques for dyeing cotton fabric and to investigate their fastness.

Pre-mordanting

Cotton samples were immersed in individual mordant solutions (CuSO4, NiCl2, FeSO4, and K2Cr2O7) at (M:L)ratio of 1:30 for two hours. The mordant bath temperature was maintained between 60°C and 85°C.After pre-mordanting, the cotton was dyed using extracted dye mixture at a same temperature at certain time.The dyed cotton fabric washed thoroughly and allowed to dry naturally in the air.

Simultaneous Mordanting

The fabric of cotton was dyed with the extracted dye mixture at 60 – 90°C for two hours.Simultaneously, the chosen mordant and dye bath, with maintaining M:L ratio of 1:30.After simultaneous mordanting and dyeing cotton then naturally air dried.

Post-mordanting

The selected fabric was bleached and dyed with the extracted dye mixture at 60 – 85°C for specific time. After dyeing, the fabric squeezed to remove excess dye solution.Subsequently, the dyed fabric was treated with a selected mordant solution with M:L ratio of 1:30.The post-mordanted fabric was washed and dried naturally in the air.Each mordanting technique was applied using different mordant chemicals (CuSO4, NiCl2, FeSO4, and K2Cr2O7) to assess their color fastness to individual effects on fabrics30.

| Figure 1: Basic structure of Anthocyanin

|

| Figure 2: Structure of Curcumin

|

| Chart 1: Process: Flowchart

|

Table 1: Natural extract with different mordants.

Name of plant present | Parts used | Nature of extract | Mordant used | Pigments |

PG + CL |

Fruit+ Rhizome |

Acidic | CuSO4 |

Anthocyanin + Curcuminoid |

| K2Cr2O7 | ||||

| FeSO4 | ||||

| NiCl2 |

*Punicagranatum L- PG;*Curcuma longa-CL

Table 2: Color sheds (Digital Synopsis).

Mordant used | Pre - mordanting shades | Post-mordanting shades | Simultaneous-mordanting shades |

CuSO4 | Denim-Blue | Olive-Green | Army-Green |

K2Cr2O7 | Flaxen-Yellow | Coffee-Brown | Peanut-Brown |

FeSO4 | Sangria-Red brown | Mink-Gray | Iron-Gray |

NiCl2 | Olive-Green | Olive-Green | Mulberry-Violet |

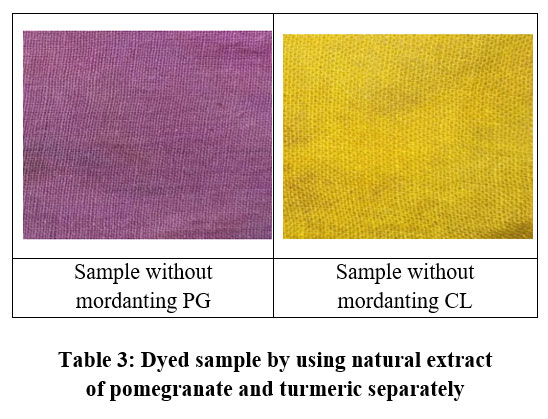

| Table 3: Dyed sample by using natural extract of pomegranate and turmeric separately

|

| Figure 3: Mixture of DE

|

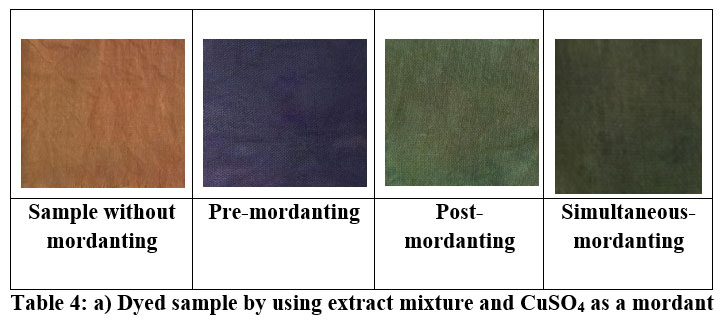

| Table 4: a) Dyed sample by using extract mixture and CuSO4 as a mordant

|

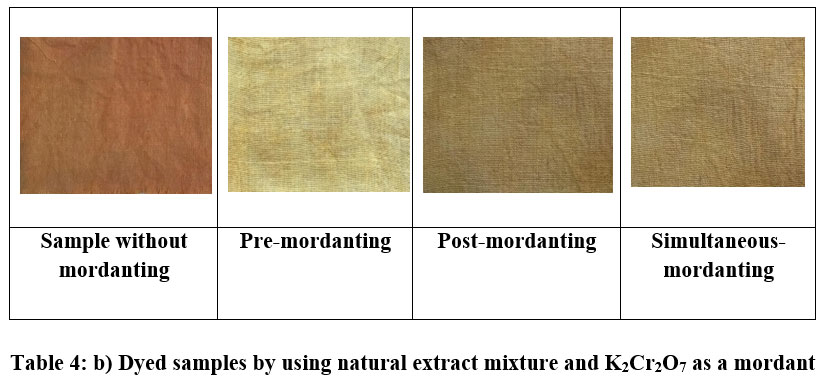

| Table 4: b) Dyed samples by using natural extract mixture and K2Cr2O7 as a mordant

|

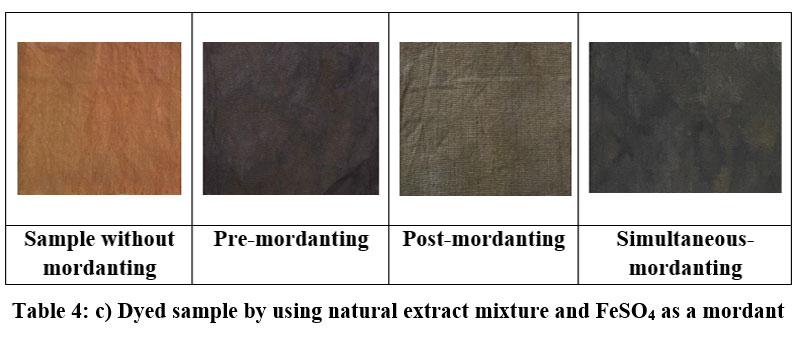

| Table 4: c) Dyed sample by using natural extract mixture and FeSO4 as a mordant

|

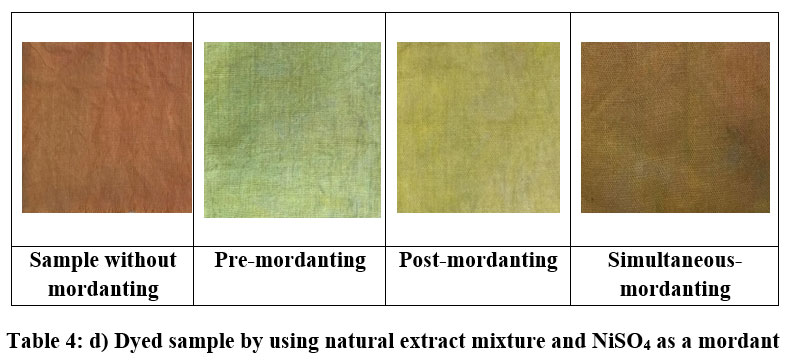

| Table 4: d) Dyed sample by using natural extract mixture and NiSO4 as a mordant

|

Result and Discussion

Natural dyes were extracted from Punica granatum L. fruit and the rhizome of Curcuma longa that produces color; it is due to Curcumin, the structure represented in Figure 2. Both dye extracts (DE) are mixed (Figure 3) the cotton fabric dyed with kind of mordents, as shown in Table 1. Colour strength depends upon the metal salts used. It also shows good fastness properties.The mordant method greatly influences cotton's natural dyeing ability with turmeric extract and Punica granatum L. Turmeric is known to have antioxidant and antimicrobial properties 31,32 .The anthocyanin pigment, Delfinidin-3-glucoside, 19% tannin, is majorly present in pomegranate juice; the basic structure is shown in Figure 1. The prepared dyes have a variety of shades such as yellowish, blue, greenish, grey-brown, reddish-brownish, and violet colors used to dye cotton fabric: Table 2, Table 4 (a-d).

The dye mixture showed good bonding with cotton fabric—yellow and green color dye found in pigments present in fruit and rhizome. The strength of color depends upon using Mordant; these metal sources play a vital role in forming a coordinated bond with dye, mordent, and fibers. Cotton fiber is a natural agricultural product highly advantageous to textile industries. It is readily available, comfortable, and has hygroscopic properties.It is natural cellulose fiber. Cotton swells in cold water and, after drying shrinks. The natural dye contains aromatic hydroxyl (-OH) and carboxyl (CO) groups. So, cotton fabric is to be treated as cationized, so cation bonding can occur. It increases the ability and capacity of dyeing. This is a simple method of dyeing cotton fabric. Attractive fresh colors were obtained. It is shown in Table 3. The quantity of dye that used also affects the intensity of fabrics 33. In nature, many species are available as dyes for dying fabrics. Searching for a new species is a new way to complete the required market demand 34.This is a new horizon for researcher to investigate the plants and their extract for different coloration. Such fabrics are suitable to wear for better health. This dyeing process was straightforward, easy, efficient, and low-cost.

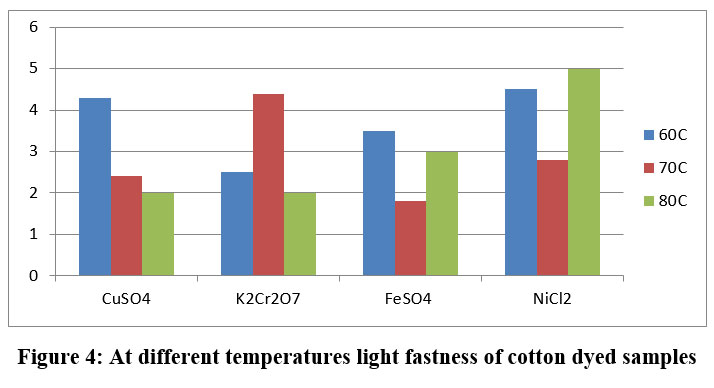

Wash Fastness

The interaction of a dye with a fiber and the dye's penetration into the fiber's interior constitute the dyeing process. The measurement of color fastness and staining analyses were conducted using a conventional test technique.35, 36, 37, 38.Table 5 shows light fastness of fabrics dyed with natural extracts with different mordants39, 40.

It associated with washing rubbing, sun exposure, ironing and use of detergents.

Table 5. Light fastness properties of cotton dyeing with natural dye

Mordants | 60 0C | 70 0C | 80 0C |

CuSO4 | 3.5 | 4 | 5 |

K2Cr2O7 | 3 | 4 | 3.5 |

FeSO4 | 4 | 5 | 5 |

NiCl2 | 2.5 | 3 | 4 |

3- 3.5 = fairly good; 4=good and 5= very good

| Figure 4: At different temperatures light fastness of cotton dyed samples.

|

New dyeing technology can help to increase quality and quantity 41.

Conclusion

This research successfully developed a sustainable dyeing process for cotton fabric dyes extracted from pomegranate and turmeric. The study highlights the potential of this dye mixture for textile applications, with key findings demonstrating its versatility and effectiveness. The extracted dye yielded a variety of colour shades with the help of various binders, offering design flexibility. Notably, employing specific mordants significantly improved the colour fastness of the dyed fabric, ensuring durability and resistance to fading. Light fastness was determined as grade 3–4 moderately well. The natural extracts possess inherent antibacterial properties, offering an added benefit for textile use. This innovative approach encourages further research into natural dyes for diverse fabrics, promoting sustainable and environmentally friendly textile production.

Acknowledgements

Authors gratefully acknowledge invaluable support from Shri G.D. Holkar, Prin. Dr. Adinath More, and the dedicated staff of the Department of Chemistry, Arts, Commerce and Science College, Lasalgaon (Nasik), Maharashtra India. Their contributions were instrumental to the research.

Funding Sources

There is no funding or financial support for this work.

Conflict of Interest

All authors at this moment clarify that, not any conflict of interest.

Authors’ Contribution:

B.B.A.: Conceptualization, design, work on materials, draft writing, editing, and manuscript preparation. S.M.K.: Design of the study and data analysis. A.B.M.: Collection of data and design and V.R.J: Writing

and editing of the review.

Ethics Approval Statement

The study doesn’t involve an experiment on humans and animals.

Data Availability Statement

Data is generated by author undertaken study

References

- Ramamoorthy S., Mudgal G., Rajesh D., Nawaz Khan F., Vijayakumar V., RajasekaranC. Characterization of novel pH indicator of natural dye Oldenlandia umbellata L. Natural Product Research 2009; 23(13) 1210-1217. https://doi.org/10.1080/14786410802696635

CrossRef - Shahid M., Mohammad F. Perspectives for natural product based agents derived from industrial plants in textile applications–a review. Journal of cleaner production 2013;(57) 2-18. https://doi.org/10.1016/j.jclepro.2013.06.004.

CrossRef - Mahesh S., Manjunatha A. H., Reddy V., Kumar, G. Studies on antimicrobial textile finish using certain plant natural products. In International Conference on Advances in Biotechnology and Pharmaceutical Sciences (ICABPS'2011) Bangkok Dec.2011 doi: 10.4236/gsc.2017.71003

CrossRef - Zia K. M., Adeel S., Aslam H., Khosa M. K., Zuber M. Influence of ultrasonic radiation on extraction and green dyeing of mordanted cotton using neem bark extract. Journal of Industrial and Engineering Chemistry 2019;(77) 317-322.doi: 10.1016/j.jiec.2019.04.054.

CrossRef - Adeel S., Ali S., Bhatti I. A.,Zsila F. Dyeing of cotton fabric using pomegranate (Punica granatum) aqueous extract. Asian Journal of Chemistry2009;21(5) 3493.

- Goodarzian H., Ekrami E. Wool dyeing with extracted dye from pomegranate (Punica granatum L.) peel. World Applied Sciences Journal 2010; 8(11) 1387-1389.

- Guo C., Wei J., Yang J., Xu J., Pang, W., Jiang Y. Pomegranate juice is potentially better than apple juice in improving antioxidant function in elderly subjects. Nutrition Research2008; 28(2)72-77. https://doi.org/10.1016/j.nutres.2007.12.001.

CrossRef - Zhao X., Yuan Z., Yin Y., Feng L. Patterns of pigment changes in pomegranate (Punica granatum L.) peel during fruit ripening. Acta Hortic 2015; 108(9) 83-89. https://doi.org/10.17660/ActaHortic.2015.1089.9.

CrossRef - Bains S., Singh O. P., Goraya G., Kang M. Dyeing of cotton with mango (Mangifera indica) dye. Journal of the Textile Association 2003;64(1)23-26.https://doi.org/10.1186/s40689-015-0007-9

CrossRef - Xia L., Wang A., Zhang C., Liu Y., Guo H., Ding C., Xu W. Environmentally friendly dyeing of cotton in an ethanol–water mixture with excellent exhaustion. Green Chemistry 2018; 20(19)4473-4483. https://DOI:10.1039/C8GC01814F

CrossRef - Yadav S., Tiwari K. S., Gupta C., Tiwari M. K., Khan A. Sonkar S. P. A brief review on natural dyes, pigments: Recent advances and future perspectives. Results in Chemistry 2022;(100)733.

CrossRef - Vankar P. S., Shanker R., Wijayapala S. Dyeing of cotton, wool and silk with extract of Allium cepa. Pigment and Resin Technology 2009;38(4) 242-247. DOI:10.1108/03699420910973332.

CrossRef - Kadolph, S. Natural dyes: a traditional craft experiencing new attention. Delta Kappa Gamma Bulletin2008;75(1) 14.

- Rehman A., Irfan M., Hameed A., Saif M. J., Qayyum M. A., Farooq T. Chemical-free dyeing of cotton with functional natural dye: A pollution-free and cleaner production approach. Frontiers in Environmental Science 2022;(10) 115. https://doi:10.3389/fenvs.2022. 848245.

CrossRef - Taylor G. W. Natural dyes in textile applications. Review of Progress in Coloration and related topics1986;16(1)53-61. https://doi.org/10.1111/j.1478-4408.1986.tb03744.x.

CrossRef - Prabhu K. H., Bhute A. S. Plant based natural dyes and mordants: A Review. J. Nat. Prod. Plant Resource 2012; 2(6) 649-664.

- Adeel S., Rehman F. U., Rafi S., Zia K. M., Zuber M. Environmentally friendly plant-based natural dyes: extraction methodology and applications. Phytochemistry and Molecular Aspects 2019; (2) 383-415. http://dx.doi.org/10.1007/978-3-030-03344-6_17.

CrossRef - Ebrahim S. A., Mosaad M. M., Othman H., Hassabo A. G. A valuable observation of eco-friendly natural dyes for valuable utilization in the textile industry. Journal of Textiles, Coloration and Polymer Science,2022; 19(1) 25-37.

- Siva R. Status of natural dyes and dye-yielding plants in India. Current science, 2007; 916-925.

- Purohit A., Mallick S., Nayak A., Das N. B., Nanda B., Sahoo S. Developing multiple natural dyes from flower parts of Gulmohur. Current science 2007; 92 (12)1681-1682.

- Vankar P. S. Dyeing Cotton, Silk and Wool yarn with extract of Garcinia mangostana pericarp. Journal of Textile and Apparel, Technology and Management 2009; 6(1).1-10

- Yusuf M., Shahid M., Khan M. I., Khan S. A., Khan M. A., Mohammad F. Dyeing studies with henna and madder: A research on effect of tin (II) chloride mordant. Journal of Saudi Chemical Society 2015; 19(1)64-72. http://dx.doi.org10.1016/j.jscs.2011.12.020.

CrossRef - Katyal R., Kakkar P., Kaur T., Tyagi T., Sharma P., Vats S., Mathur R. Colouring Properties of Plant Pigments on Fabric: Survey on Preference for Antimicrobial Naturally Dyed Mask. Current Trends in Biotechnology and Pharmacy 2021; 15(6)53-57.

- Kumaresan M. Application of eco-friendly natural dye obtained from Spathodea campanulata on silk using combination of mordants. Management of Environmental Quality: An International Journal 2016; 27(1)15-21. https://doi.org/10.1108/MEQ-04-2015-0061

CrossRef - Arora J., Agarwal P., Gupta G. Rainbow of natural dyes on textiles using plants extracts: Sustainable and eco-friendly processes. Green and Sustainable Chemistry 2017; 7(1), 35-47. https://doi:10.4236/gsc.2017.71003.

CrossRef - Jiang H., Guo R., Mia R., Zhang H., Lu S., Yang F., Liu H. Eco-friendly dyeing and finishing of organic cotton fabric using natural dye (gardenia yellow) reduced-stabilized nanosilver: full factorial design. Cellulose 2022; 29(4) 2663-2679. doi: 10.1007/s10570-021-04401-9.

CrossRef - Shahid A. Bhatti A. Ijaz Kausar, Asfah, EmanO. Influence of UV radiations on the extraction and dyeing of cotton fabric with Curcuma longa L., Indian Journal of Fibre and Textile Research 2012;37(1) 87?90.

- Srivastava M., Mogra D., Gupta P. Dye extraction from Rheum emodi for colouring silk using natural mordants. Journal of Applied and Natural Science 2015; 7(1) 182-186.

CrossRef - Wanyama P. A. G., Kiremire B. T.,Murumu J. E. S. Extraction, characterization and application of natural dyes from selected plants in Uganda for dyeing of cotton fabrics. African Journal of Plant Science 2014;8(4) 185-195.

CrossRef - Bydoon E. A. Extraction of natural dye from tea leaves and its application on Giza 86 Egyptian cotton fabric. International Journal of Advanced Science and Engineering 2017; 3(4) 455-462.

- Ali N. F., Mohamedy R. E., El-Khatib E. M. Antimicrobial activity of wool fabric dyed with natural dyes. Research Journal of Textile and Apparel 2011; 15(3) 1-10. https://doi.org/10.1108/RJTA-15-03-2011-B001

CrossRef - Samanta A. K., Konar A. Dyeing of textiles with natural dyes. Natural dyes 2011; 3 (30-56).

- Mahanta D., Tiwari S. C. Natural dye-yielding plants and indigenous knowledge on dye preparation in Arunachal Pradesh, northeast India. Current science 2005; 1474-1480.

- Rehman A., Irfan M., Hameed A., Saif M. J., Qayyum M. A., Farooq T. Chemical-free dyeing of cotton with functional natural dye: A pollution-free and cleaner production approach. Frontiers in Environmental Science 2022;(10) 115. DOI:10.3389/fenvs.2022.848245

CrossRef - Meng X., Wang X., Wang P., Miao D.,Ning X. Enhanced dyeability and wash fastness through a salt-free plasma-induced grafting of cationic monomers on cotton fabrics. Fibers and Polymers 2021 ;( 22) 3378-3384. doi: 10.1007/s12221-021-1105-8.

CrossRef - Harlapur S., Harlapur S. Ecofriendly Antimicrobial Dyeing for Cotton Fabric Using Natural Extract of Marigold. Turkish Journal of Computer and Mathematics Education 2021; 12(2), 957-962.

CrossRef - Park, Y. Characteristics of cotton fabric dyed with Euphorbia extract at different concentrations of cellulosic nanoparticles (CNP). Fash Text 2023, 10, 3. https://doi.org/10.1186/s40691-022-00319-3

CrossRef - Choi, Na-Young, and Bog-Im Park."Dyeing Performance and Anti-Superbacterial Activity of Cotton Fabrics Dyed with Chamaecyparis obtusa" Molecules 2023; 28(18) 6497. https://doi.org/10.3390/molecules28186497

CrossRef - A.T.M.Gulam Moula,Md.Dulal Hosen,Md. Abu Bakar Siddiquee, Md.Abdul Momin, Zihan Kaisar,Md.Abdullah Al Mamun,Md. Azharul Islam. Effect of dye bath pH in dyeing of cotton knitted fabric with reactive dye (Remazol Yellow RR) in exhaust method: impact on color strength, chromatic values and fastness properties. Heliyon 2022 8,11 DOI:https://doi.org/10.1016/j.heliyon.2022.e11246

CrossRef - Hosen M.D.,Rabbi M.F.,Raihan M.A., Mamun M.A. Effect of turmeric dye and biomordants on knitted cotton fabric coloration : a promising alternative to metallic mordanting. Cleaner Engineering and Technology. 2021; 3: 1-11

CrossRef - Niu T., Wang X., Wu C., Sun D., Zhang X., Chen Z., Fang L. Chemical modification of cotton fabrics by a bifunctional cationic polymer for salt-free reactive dyeing. ACS omega 2020; 5(25), 15409-15416.

CrossRef