Mineralogical Study of Respirable Dust in Artisanal Small-scale Quarries of Misisi Compound, Lusaka, Zambia

1

University of Zambia,

School of Mines, Department of Mining Engineering,

Lusaka,

Zambia

2

University of Zambia, School of Mines,

Department of Metallurgy and Mineral Processing,

Lusaka,

Zambia

Corresponding author Email: vmutambo@unza.zm

DOI: http://dx.doi.org/10.12944/CWE.18.1.13

Copy the following to cite this article:

Mutambo V, Munchini C. Mineralogical Study of Respirable Dust in Artisanal Small-scale Quarries of Misisi Compound, Lusaka, Zambia. Curr World Environ 2023;18(1). DOI:http://dx.doi.org/10.12944/CWE.18.1.13

Copy the following to cite this URL:

Mutambo V, Munchini C. Mineralogical Study of Respirable Dust in Artisanal Small-scale Quarries of Misisi Compound, Lusaka, Zambia. Curr World Environ 2023;18(1).

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2022-08-02 |

|---|---|

| Accepted: | 2023-03-21 |

| Reviewed by: |

David D Massey

David D Massey

|

| Second Review by: |

Nguyen Thi Dong

Nguyen Thi Dong

|

| Final Approval by: | Dr. Gangadhar Andaluri |

Introduction

Dust in quarry mining operations mainly comes from the mechanical breakdown of the parent rock during drilling, blasting, chiseling, chipping, crushing and grinding. Other sources of dust at quarry mine sites include: polishing, screening, weighing, mixing, loading and hauling operations. Larger particles of dust usually settle down while very fine dust remains suspended in air. This type of dust is referred to as primary airborne dust. In most cases, the composition of mineral dust is different from the parent rock depending on the type of dust generating activity and the rate of dust emission1. The concentration of dust and exposure can range between 10 to 100 mg/m3 depending on the type of mining operation. The Time Weighted Average (TWA) refers to the average airborne exposure of a worker in an 8-hour work shift. This criterion is commonly used for determining exposure levels.

To date, there are several cases of occupational dust exposures that have been recorded at quarry mining operations in Brazil 2, Britain 3 , China 4, India 5 and the United States 6. In a study conducted at a quarry mining site in Mahendragarh, Haryana in India, it was established that drilling, blasting, crushing, and transport of mined material were responsible for the generation of a substantial quantity of dust7. In the UK, quarrying activities contribute less than 5% of PM10 emissions and just 1% of PM2.5 emissions8. The main activities contributing to dust emission in the UK at the quarries are: overburden handling, drilling and blasting; crushing and screening; storage of minerals at the sites; transportation and loading and storage of overburden and soil8. In the USA, many stone quarrying sites produce dust from drilling or blasting operations. The particulate matter produced range from relatively large particle size to smaller particles9. Quarries in Turkey are commonly associated with negative impacts associated with dust emission and deposition on the settlements in the surrounding areas and visual obstruction10. The mineralogical and chemical composition of dust particles have direct impacts on the health of an individual11. Mining and quarrying activities by nature have the potential to emit dust in varying concentrations that ultimately result in health effects12.

In most cases, workers are unaware of the extent and degree of dust exposure at quarries until they develop fatal respirable related diseases. However, putting in place adequate control measures can lead to a reduction of exposure levels13, 9. Respirable dust particles, because of their small size, may reach the alveoli when inhaled.

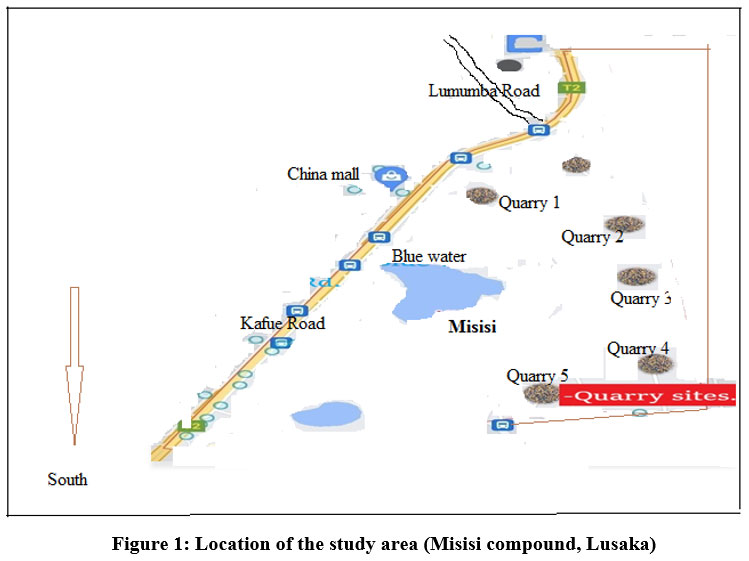

In Misisi compound of Lusaka, Zambia, it is very common to see men, women, and children crushing dolomite and limestone on quarry mining sites14. Even though crushed stones are a geological commodity from which almost everything for construction is built, it generates a wide range of occupational health exposure and safety hazards15. This is due to the fact that workers working in quarries, most often extract rocks without following safety procedures and standards. Among the most notable is the lack of Personal Protective Equipment (PPE) such as face masks. The use of crude tools such as chisels, iron hammers, crowbars, and shovels is very common14. Non-compliant to safety standards coupled with strenuous and labour-intensive work necessitates hazards due to slips and trips16. Dust from the quarry mine sites can be a major source of air pollution despite the fact that the severity depends on factors such as local microclimate and dust particle size. Dust can cause a variety of respiratory diseases such as silicosis and pneumoconiosis amongst quarry workers17, 18, 19. The location of the study area is shown in Figure 1. The area is generally flat and dotted with many pits of which some have since been abandoned. Predominantly, there are five active quarry mining sites as shown in Figure 1. The major activities undertaken at these quarries are; rock digging, chiseling, loading/transportation and crushing/screening. Rock digging is carried out with the help of hammers after subjecting the rock to intense heating while chiseling is carried out with the help of chisels. Rock crushing and screening are carried out with the help of hammers and screens respectively. The major sources of dust at the quarries are rock-crushing and screening. The number of people working at one quarry may range from 10 to 30.

| Figure 1: Location of the study area (Misisi compound, Lusaka).

|

This study assessed the respirable dust and mineralogical composition of rock samples in selected artisanal quarries of the Misisi Compound. The significance of this study is that it will enable the government to develop specific guidelines on occupational health and safety programs at work places for artisanal small-scale quarry miners.

Hazardous nature of Dust

The International Standardization Organisation, defines dust as small solid particles below a diameter of 75 ?m which remain suspended in air for some time or settle down under their own weight20.

Accordingly, classification of dust can be based on the following categories21. Inhalable dust fraction – This fraction of dust refers to dust particles that are trapped in the mouth or nose when a breath is taken in. Thoracic dust fraction - This fraction of dust can penetrate the air passage and enter the lungs. Respirable dust fraction- This is a fraction of airborne particles that are inhaled and passed to the small pockets of the lung called alveoli. According to Occupational Health Services Australia22, dust particles of less than 5 microns can pass into the lungs. Health and Safety 23 states that respirable particles are usually more hazardous than inhalable dust. Respiratory diseases such as silicosis and bronchitis have been reported at quarry sites with high concentration of respirable dust containing free crystalline silica12. The severity of these diseases depends on the particle size of the dusts, their mineralogy, mass concentration inhaled, period of exposure and to some extent shape of the particles.

Dust sampling techniques

There are a number of methods used for sampling dust such as gravimetric, optical, electrical, and thermal sampling. According to jay24, the notable methods of sampling dust in metallic and non-metallic mines are gravimetric samplers, personal data ram (pDR), and personal dust monitors (PDM).

Gravimetric samplers measure both respirable and inhalable dust concentration based on Time Weighted-Average. The samplers consist of a pump and the cyclone assembly that separates respirable and total dust. The cyclone is further attached to a cassette. According to Belle 25, the type of cyclone used flow rate and variations in flow rate affect the size fraction sampled. In evaluating various gravimetric samplers, he further noted that while increasing the flow leads to larger volumes drawn, the dust drawn is of smaller mean particle size. However, in terms of usability, the gravimetric-based methods are not complicated provided other variables such as moisture, sample handling and temperature are taken into account26.

Gravimetric sampling procedures for measuring dust and other aerosols are fully described by the Occupational Safety and Health of America (OSHA)27. Personal Data RAM is based on light scattering as measurement technology. The device measures Instantaneous readings which are correlated with time and stored in internal memory.

Personal Dust Monitor (PDM) applies a mass-based measurement method to quantify dust concentration levels. The measurements are in real-time and are displayed on screen for later analysis.

Methods and Materials

Sampling procedure and design

The in-built battery of the gravimetric sampling pump was charged for 16 hours using a master charger before being taken in the field for use. The pump was calibrated using the BUK calibrator to a flow of 1.5 - 2.5L/min. Filters together with the reference ones were weighed before use and their masses were recorded respectively.

Actual field sampling commenced after selecting employees from specified quarries and discussing with them the purpose of sampling. The importance of not removing or tampering with the sampling equipment was emphasised. Each employee at the quarry was assigned with one dust sampler which was later hooked to his/her waist with the help of the belt. The sampling equipment was placed in such a way that it did not interfere with work performance of the employee. The pump was stopped and finally time was recorded with a stop watch after the sampling period. Measurements of dust were conducted in the down-wind direction. The sampling time was pegged at one hundred and twenty minutes (120 minutes).

The pump operations were observed for about 15 minutes to ensure that the flow rate was stable and that neither the employee nor the dust sampler was interfering with the operations of the other. The collection devices such as the filter cassette were attached to the shirt collar close to the nose and mouth of the employee in front of the shoulder’s hemisphere within a radius of 15.24 to 22.86 cm. Samples were collected from employees after 2 hours. In instances where the employee could not carry the sampler, it was placed at a height of more than one meter above the ground surface to avoid sampling dust from the ground as shown in Figure 2.

| Figure 2: Dust sampling at a crushing site, quarry No.4 in Misisi Compound.

|

Before switching off the pump at the end of the sampling time, the flow rate was checked again for stability. In order to prevent non-respirable dust particles from grit pot of cyclone to the filter, the sampling head had to be kept upright. The collected filters from the cassettes were placed in small petri dishes and were left partially opened for 24 hours in order to drive out the moisture. At this time, the reference filter was also exposed to similar conditions before they were both weighed again. After 24 hours, both the dust-laden filter and the clean reference were weighed and the masses recorded. All the readings from the filters were tabulated and the dust masses computed.

The pump drew air through the sampling head at a flow rate of 2.5 l/min. At this flow rate, the elutriator has a retention characteristic defined by the penetration curve for respirable aerosols.

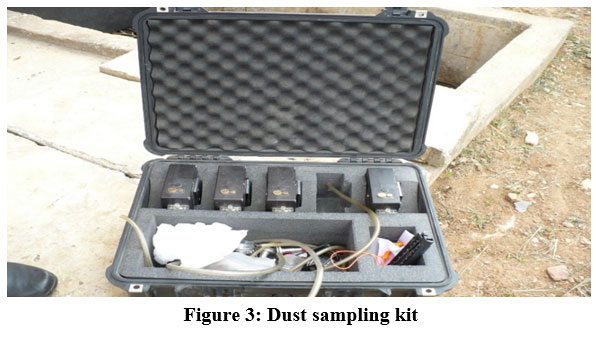

Prior to the next sampling, all components of the cyclone including the grit pot were cleaned with mild soapy water. The cyclone was then wiped with a clean dust-free tissue. Figure 3 shows the gravimetric pump and assembly used in the study.

| Figure 3: Dust sampling kit.

|

Governing equations

The difference between the initial weight of the filter paper, W1, and the weight of the filter paper after sampling, W2 gave the weight of the dust which accumulated during the sampling period.

.jpg)

Where;

W1 - initial weight of filter paper before sampling

W2 - weight of filter paper after sampling

W - weight of dust which accumulated.

Note: All weights are in milligrams (mg)

Sampling time was obtained by getting the difference between the starting time, t1 and the ending time,

Where;

t1 - start time

t2 - end time

t - Sampling time

Note: All times are in minutes (min)

The flow rate was recorded as it appeared on the flow metre of the pump. Constant checks were done to make sure that it remained constant during the whole sampling period. Flow rate, Q was in litres per minute, (l/min). The volume of air, V, which flowed during the entire sampling time, t is given by the product of sampling time, t and flow rate, Q.

In litres.

Dust concentration, DC for each sampling time is given by dividing the volume, V into the weight of dust which accumulated, W.

Dust concentration, (mg/I) i.e. in milligrams per litre.

For a number of sampling times, n conducted on one subject, an average value, DCavg was calculated. Average dust concentration, where n is the number of times a subject has been investigated, DCi is the individual dust concentration.

For the whole shift, therefore, the time-weighted average, TWA can be considered and is determined as

Where, t0 = (Eti )/n that is the average time of sampling for the individual subject.

But shift hours are 8, therefore,

or

Mineralogical examination

The solid rock samples from the quarry pits were analysed for silica and particulate matter content based on the petrographic microscopic thin section method. The concentration of silica and other particulate matter in the rock samples were determined by the point counting method which is based on identifying the mineral or grain present at a large number usually between 150 to 500 of points on a petrographic thin-section slide.

Results

Measured respirable dust concentrations from five (5) selected quarries.

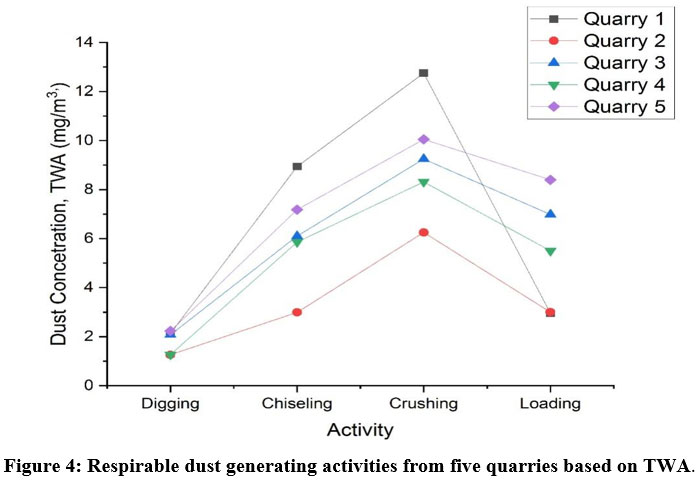

Table 2 shows the results of average measured respirable dust concentrations from five (5) quarry sites while Figure 4 shows the comparison of respirable dust-generating activities based on TWA.

Table 2: Average measured dust concentrations from five (5) quarry sites

Site | Activity | Initial mass of filter paper (mg) | Final mass of filter | Respirable dust (mg) | Dust concentration(mg/m3) | On 8 hr shift basis (min) | TWA@ 8hrs |

1 | Digging | 44.45

| 47.01 | 2.56 | 8.51 | 480 | 2.13 |

Chiselling | 55.21 | 10.76 | 35.75 | 8.94 | |||

Crushing | 59.80 | 15.35 | 51 | 12.75 | |||

Loading | 48.00 | 3.55 | 11.8 | 2.95 | |||

2 | Digging | 45.6

| 47.12 | 1.52 | 5.05 | 480

| 1.26 |

Chiselling | 49.20 | 3.6 | 11.96 | 2.99 | |||

Crushing | 53.22 | 7.62 | 25 | 6.25 | |||

Loading | 49.24 | 3.64 | 12 | 3.0 | |||

3 | Digging | 44.3

| 46.8 | 2.5 | 8.31 | 480 | 2.08 |

Chiselling | 51.64 | 7.34 | 24.39 | 6.10 | |||

Crushing | 55.5 | 11.2 | 37.21 | 9.25 | |||

Loading | 52.7 | 8.4 | 27.91 | 6.98 | |||

4 | Digging | 46.5 | 48.03 | 1.53 | 5.08 | 480 | 1.27 |

Chiselling | 53.55 | 7.05 | 23.45 | 5.86 | |||

Crushing | 56.5 | 10 | 33.22 | 8.31 | |||

Loading | 53.41 | 6.91 | 22 | 5.5 | |||

5 | Digging | 44.6 | 47.29 | 2.69 | 8.94 | 480 | 2.23 |

Chiselling | 53.24 | 8.64 | 28.71 | 7.18 | |||

Crushing | 56.7 | 12.1 | 40.20 | 10.05 | |||

Loading | 54.8 | 10.2 | 33.89 | 8.40 |

The results of the measured dust in Table 2 indicated high levels of respirable dust concentration at all five (5) quarries. Quarry No.1 recorded the highest respirable dust concentration of 12.75 mg/m3 (TWA) at the crushing site against the maximum allowable concentration of 5 mg/m3.

| Figure 4: Respirable dust generating activities from five quarries based on TWA.

|

As can be seen in Figure 2, all crushing activities at all five quarries recorded high levels of respirable dust while all the digging activities had the lowest levels.

Mineralogical examination

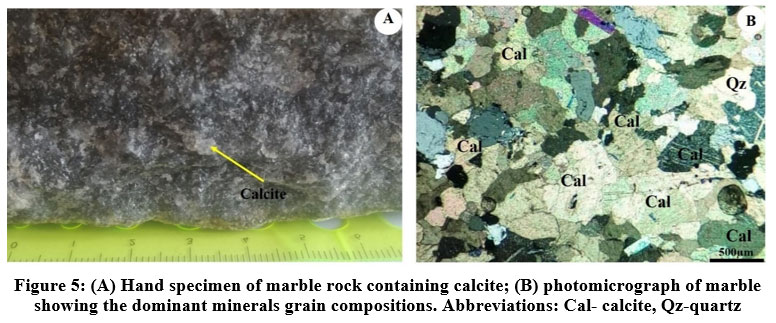

The results of mineralogical testing and analyses revealed that marble (Figure 5) was the common rock type that was being mined by most of the ASM in the studied area. Marble by definition is a metamorphic rock composed of calcium carbonate (CaCO3) with a minor amount of silica (SiO2) content. Based on the point count data analysis, marble from all the five (5) quarries contained an average of about 98% CaCO3 and 2% SiO2 (Figure 5B). Although dust from marble rocks showed lower concentrations of SiO2, these concentrations might vary from place to place depending on chemical processes existing during their rock formations31. Regardless of the low SiO2 content in marble, the exposure due to the long working hours at quarry mine sites by the ASM can make them vulnerable to developing silicosis and cancer diseases. These results are consistent with similar research studies conducted by Pelucchi et al.32which revealed that prolonged exposure to low SiO2 and high amounts of particulate matter concentration can lead to severe cancer diseases in humans.

| Figure 5: (A) Hand specimen of marble rock containing calcite; (B) photomicrograph of marble showing the dominant minerals grain compositions.

|

Solutions to control dust from quarry mining operations

Dust generation at quarries cannot be completely eliminated because mining and crushing activities are all associated with dust. However, there are several methods that can be used to control dust at quarry mine sites. These include water suppression method, engineering control, management control and use of personal protective equipment (PPE) in form of dust masks. Wet suppression involve the use of water for spraying and wetting fine particles suspended in air. In order to achieve wetting of these particles it is better to use fine atomized spray or mist sprays having droplets of about 60 ?m diameter33. Engineering control of dust at the quarry can involve the substitution of hand held hammers with modern crushers that are enclosed. The use of such a crusher is a far-fetched dream for most artisanal and small scale miners in Misisi compound due to the high cost of crushers. The type of dust control that can easily be applied is management control. This requires implementation of work schedules and rotations at a work place in order to reduce the number of hours of exposure to dust more especially on crushing sites. The use of dust respirators should be encouraged at all operational sites.

Discussions

The results from Misisi compound quarry sites indicate very high concentrations of respirable dust which can be very hazardous to the health of workers depending on the chemical composition of the dust. Dust concentrations (TWA) at most sampling points were above 3 mg/m3. The American Conference of Governmental Industrial Hygienists (ACGIH) recommends guidelines of 3 mg/m3 respirable for insoluble or poorly soluble particles for 8-h time-weighted average (TWA) exposures28. The highest respirable dust concentrations were recorded at crushing points in contrast to the study carried out in Tanzania, where blasting indicated the highest dust levels. 29 The TWA respirable dust concentration associated with crushing at all sampling points exceeded the ACGIH OEL set standard of 3mg/m3 and did not differ significantly from respirable dust samples recorded in Tanzania29. However, there was a significant difference with a study conducted on mineral dust exposure among young Indian adults which recorded 37.9 mg/m3 of 8 hour TWA30. Most of the participants found at the crushing points in Misisi compound were females consisting mainly of elderly people.

Conclusion

Artisanal small-scale quarry mining activities have continued to increase in Misisi Compound largely due to the growth of the construction sector in Lusaka. This study sought to assess the mineralogical dust composition and concentration of dust at artisanal quarries.

The following are the findings:

- ASM in Misisi is subjected to high respirable dust concentration. The highest values of respirable dust concentration (TWA) were recorded at quarries No. 1, 2, 3 and 5 from crushing activity (8.31-12.75mg/m3). Such concentration levels of respirable dust can endanger the health of the miners and lead to chronic respiratory diseases.

- The TWA respirable dust concentration associated with crushing at all sampling points exceeded the ACGIH OEL set standard of 3mg/m3 . This implies that the most exposed people in the quarry mines at Misisi compound are those engaged in crushing activities. The TWA respirable dust at all digging sites were below the set standard according to ACGIH OEL.

- The XRD micro-structure analysis for PM 2.5 and PM 10 showed that dust samples contained an average of 2% elements of silicon dioxide (SiO2) and 98 % calcium carbonate (CaCo3) at all 5 quarry mining sites.

Acknowledgement

We would like to thank The University of Zambia, School of Mines and the Education for Sustainable development in Africa (ESDA) program for logistical support.

Conflict of Interest

The authors would like to state that there is no potential conflict of interest that may arise from the publication or dissemination of this study.

Funding Sources

This study did not receive any funding from any source.

References

- Knight G (1980). Generation and Control of Mine Airborne Dust, CANMET Report 80-27E. Energy, Mines and Resources Canada, Ottawa, Canada.

- Ribeiro Franco A (1978). Silicose Pulmonar Nos Trabalhadores em Pedreiras, Revista Brasileira de Saúde Ocupacional, FUNDACENTRO, São Paulo, Brazil (in Portuguese)

- Maguire BA, Saunders E, Harris GW (1975). Respirable dust sampling in British quarries. Staub -Reinhaltung der Luft 35(11):397-400.

- Zou C, Gao Y, Ma Q (1997). Pneumoconiosis in China: Current situation and countermeasures. Asian-Pacific Newsletter on Occupational Health and Safety 4(2):44-49.

- Durvasula R (1990). Occupational health information systems in developing countries - India, a case study, presented at the IV Takemi Symposium in International Health - Working Populations and Health in the Third World: Problems and Policies, 29 September - 1 October 1990, Harvard School

- Ayer HE, Dement JM, Busch KA, Ashe HB, Levadie BTH, Burgess WA, DiBerardinis L (1973). A monumental study - reconstruction of an 1920 granite shed. American Industrial Hygiene Association Journal 34:206-211

- Ambastha, S.K., Haritash, A.K. Emission of respirable dust from stone quarrying, potential health effects, and its management. Environ Sci Pollut Res 29, 6670–6677 (2022). https://doi.org/10.1007/s11356-021-16079-4

- Mineral Products Association (2022). Quarries and Dust, UK. Available at:// https://mineralproducts.org/MPA/media/root/Publications/2022/MPA_Quarries_and_Dust_Air_Emissions_2022.pdf , Accessed 08/02/23.

- Limestone and Crushed Rock (1992). Crushed rock. Energy and Environmental Profile of the U.S. Mining Industry, Chapter 9, Pp: 1-12. Available at: https://www.energy.gov/sites/prod/files/2013/11/f4/stone.pdf, Accessed: 08/02/2023 , . In the USA,

- Gökhan KÜLEKÇ? (2022). A case study on dust formation in mining operations and its effect on human health; calculating a quarry dust emission amount. International Journal of Health Sciences. Vol: 5, Issue: 8 pp:1- 10.

- Duarte, J.; Castelo Branco, J.; Rodrigues, F.; Vaz, M.; Santos Baptista, J. (2022) Occupational Exposure to Mineral Dust in Mining and Earthmoving Works: A Scoping Review. Safety, 2022, Vol: 1, Issue 9. https:// doi.org/10.3390/safety8010009

- Swuste PHJJ (1996). Occupational Hazards, Risks and Solutions. PhD thesis. Delft University Press, Delft, The Netherlands.

- An Overview of Artisanal and Small- Mining in Zambia. (2019). Lusaka: Oxfam.

- Horbart, M. K., (2021). Crushed Stone-The Unsung Mineral Hero; it is the geologic commodity upon which almost everything is built. Geology.com. Accessed December 5, 2021.

- Hentschel, T., Hruschka, F and Priester, M. (2003) Artisanal and Small-scale Minning. Challenges and Opportunities. London: IIED

- Rees, D. and Murray, J. (2007). Silica, silicosis and tuberculosis. [State of the Art Series. Occupational lung disease in high-and low-income countries, Chan-Yeung M, editor. Number 4 in the series]. Int J Tuberc Lung Dis. 11:474-484.

- Schneider, T. and Bohgard, M. (2005). Airborne particle deposition into ocular surface. PMID: 15865621. PubMed

- Wanjiku, M.K, et al. (2015). Effects of Quarrying Activities on Occupational Health among Quarry Workers in Mutonga, Quarry, Meru County. Kenya Prime Journal of Social Sciences (PJSS) ISSN: 2315-5051. Vol. 3(8), pp. 812-817.

- ISO (1995). Air Quality - Particle Size Fraction Definitions for Health-related Sampling. ISO Standard 7708. International Organization for Standardization (ISO), Geneva.

- World Health Organization. Occupational and Environmental Health Team. (?1999)?. Hazard prevention and control in the work environment: : airborne dust. World Health Organization. https://apps.who.int/iris/handle/10665/66147

- Occupational Health Services Australia (OHSA). Available at: https://www.ohsa.com.au/services/dust-monitoring/

- Health and Safety (2011). Dust in the Workplace. Guidance for Health and Safety Representatives. Puc, Pp. 1-7. Available at: https://www.tuc.org.uk/sites/default/files/DUSTWorkplace.pdf

- Jay Colinet (2010). Dust Sampling Instrumentation and Methods. Silica Dust Control Workshop Elko, Nevada

- B. Belle (2018). Evaluation of gravimetric sampler bias, effect on measured concentration, and proposal for the use of harmonised performance based dust sampler for exposure assessment. International Journal of Mining Science and Technology Volume 29, Issue 3, May 2019, Pages 445-452

- O'Connor, S., O'Connor, P. F., Feng, H. A., & Ashley, K. (2014). Gravimetric Analysis of Particulate Matter using Air Samplers Housing Internal Filtration Capsules. Gefahrstoffe, Reinhaltung der Luft = Air quality control, 74(10), 403–410.

- Industrial Hygiene Chemistry Division (2003). Gravimetric Determination. OSHA Salt Lake Technical Center. Pp: 1-15. Available at: https://www.osha.gov/sites/default/files/methods/OSHA%202121.pdf. Accessed 20/06/2022

- John Cherrie, Alastair Hay, and Lisa M Brosseau, Kenneth Donaldson (2013) Low-Toxicity Dusts: Current Exposure Guidelines Are Not Sufficiently Protective. Annals of Occupational Hygiene

- Naidoo RN, Kessy FM, Mlingi L. (2009) Respiratory health of stone crushers from the informal sector in Tanzania. Occup Health Southern Afr.; 15(6):6-13.

- Green DA, McAlpine G. Semple S, Cowie H, Seaton A. (2008). Mineral dust exposure in young Indian adults: an effect on lung growth? Occup Environ Med. 2008; 65(5):306-310

- J. Varela, C.O. Petter, H. Wotruba, (2006) Product quality improvement of Brazilian impure marble, Minerals Engineering, Volume 19, Issue 4, Pages 355-363,https://doi.org/10.1016/j.mineng.2005.10.009

- Pelucchi C, Bosetti C, Negri E, Malvezzi M, La Vecchia C (2006). Mechanisms of disease: the epidemiology of bladder cancer. Nat ClinPract Urol 3: 327 – 340

- Spray technology for dust control. A guide to selecting the optimal spray system for your application. Available at: https://mt-spray.dk/wp-content/uploads/B652A_Dust_Control_Bulletin.pdf, Accessed 16/02/2023