Optimizing Soil Performance: Using Cement Kiln Dust along with Polymer Integration for Soil Stabilization

1

I. K. Gujral Punjab Technical University,

Jalandhar,

Panjab

India

Corresponding author Email: dr.rajivchauhan@ptu.ac.in

DOI: http://dx.doi.org/10.12944/CWE.19.3.6

Copy the following to cite this article:

Chauhan R, Suman A, Singh S. Optimizing Soil Performance: Using Cement Kiln Dust along with Polymer Integration for Soil Stabilization. Curr World Environ 2024;19(3). DOI:http://dx.doi.org/10.12944/CWE.19.3.6

Copy the following to cite this URL:

Chauhan R, Suman A, Singh S. Optimizing Soil Performance: Using Cement Kiln Dust along with Polymer Integration for Soil Stabilization. Curr World Environ 2024;19(3).

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2024-09-26 |

|---|---|

| Accepted: | 2025-01-03 |

| Reviewed by: |

Rajendra Bhadauria

Rajendra Bhadauria

|

| Second Review by: |

Renuka

Renuka

|

| Final Approval by: | Dr. Hiren B Soni |

Introduction

Municipal Solid Waste (MSW) is a challenge in growing urban areas, especially in developing countries like India, due to rapid urbanization and population growth. MSW comprises residential, industrial, construction, municipal and commercial waste. The volume of garbage poses significant challenges for waste management in developing regions like Punjab, India with cities such as Jalandhar facing severe issues. MSW landfills exacerbate problems like landfill gas emissions, odors and leachate leakage which harms soil and groundwater.

The pioneer research on oil contaminated soils were carried on the effects of stabilizers on diesel- contaminated soil, assessing changes in permeability, hydrocarbon and heavy metal levels, compaction properties, and compressive strength using materials like cement kiln dust and Ordinary Portland.1-4 The solidification of heavy metals with OPC and fly ash on the contaminated soil was also explored.5-7 The dump sites generate wastewater that further contaminates soil and groundwater emphasizing the need to understand these interactions for environmental and public health reasons. Leachate, a liquid byproduct of MSW contains high concentrations of toxic substances due to the organic and inorganic chemicals released from waste. The study investigated leachate toxic materials that contain arsenic thereby contaminating soil and groundwater by percolate through soil layers.8,9 Heavy metals having lead contaminated soil studied by few researcher.10-12 The oil contaminated soil and its solidification has been also studied for environmental effects.13,14

The polymer has controlling effect on liquefaction phenomenon and used synthetic polymers on soil stabilization.15,16 The reviewed studies collectively address various aspects of soil contamination and stabilization techniques, highlighting their environmental and engineering implications. Their findings stress the need for comprehensive studies to understand soil contamination's impacts on ecosystems and human health, advocating for proactive waste management in urban areas.

The present study explores an innovative approach to soil stabilization by mitigating contamination with use of Cement Kiln Dust (CKD) and epoxy liquid polymer. The addition of CKD at varying proportions (5%, 10%, and 15%) with and without epoxy for liquid limit, plastic limit, and plasticity index and Compressive strength gain, thereby improving soil workability and stability.

Materials and Methodology

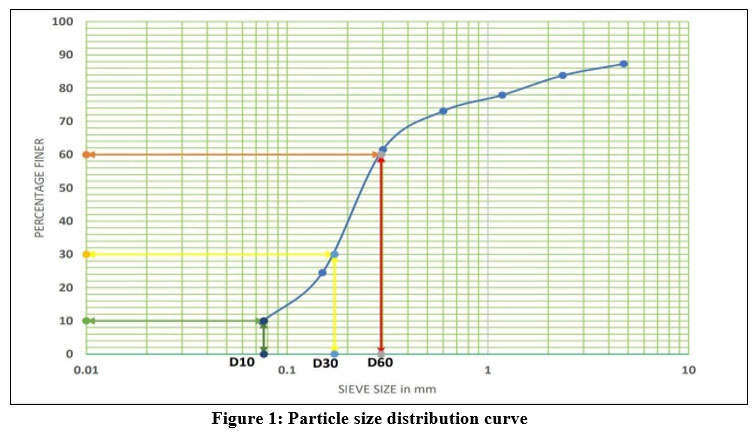

Contaminated soil was collected from the dump of Wariana, Jalandhar, Punjab, India. After removing the organic layer on top, we placed the soil on a floor and used a hand roller to break down any lumps. Next, we sifted soil using No. 4 sieve to eliminate unwanted vegetative materials and pebbles. The soil was the air dried and stored in plastic bags. In a lab, the physical characteristics of polluted soil were assessed. Cement kiln Dust(CKD) was acquired from an Indian cement mill in Himachal Pradesh. The Characteristics of contaminated soil and CKD are mentioned in Table1 and 2. The Fig 01 shows Particle size distribution curve.

Epoxy Liquid Polymer

Epoxy polymer was collected from the main market of the city Jalandhar, Punjab, India. Epoxy Resins are formed by the reaction between nepichlorohydrin with bisphenol Epoxy Resins have ingredients i.e. plasticizer, hardener, an accelerator and the monomeric resin. Epoxy resin are chemical organic compounds. It consists of atoms such as sulfur hydrogen, carbon, nitrogen an a little of oxygen.

Table 1: Physical Parameters of Contaminated soil

Physical Characters | Values |

Specific Gravity | 2.42 |

OMC (%) | 14 |

MDD (g/cc) | 1.6 |

UCS (kN/m2) | 84.60 |

LL | 28 |

PL | 16 |

PI | 12 |

pH | 5.2 |

Cohesion | 13.92676 |

Angle of Friction(?) | 6.675522 |

Table 2: Chemical Parameters of Cement kiln dust

Chemical Composition | Cement kiln dust |

Cao | 55.06 |

SiO2 | 11.9 |

Al2O3 | 9.9 |

Fe2O3 | 3.4 |

SO3 | 1.48 |

MgO | 1.7 |

Na2O | 0.5 |

K2O | 0.1 |

Loss of ignition | 4.7 |

| Figure 1: Particle size distribution curve.

|

Specimen Preparation

Contaminated soil was mixed manually in its dry state with CKD and liquid polymer. The necessary water content was then mixed, ensuring thorough mixing for minimum 6 minutes and squeezing to eliminate any air. The standard Proctor test was utilized to analyze the Optimum Moisture Content (OMC) content and Maximum Dry Density (MDD) for each mixture. Unconfined Compressive Strength (UCS) and California bearing ratio (CBR) specimens were prepared in cylindrical shapes moulds. The weight and density were done as per IS static compaction test. These samples were then stored in desiccators until they were examined at 7- and 14-days post-curing.

For CBR Test17, the sample was prepared using a mold that conforms to the compaction test. The test was conducted using a plunger with a diameter of 5 cm, and the reading was taken at a penetration of 5.0 mm.

Experimental Program for Testing

The contaminated soil was dried in the oven for 24 hours. The Table 3 shows the test details for various combinations of C.S and CKD with CKD and liquid polymer for testing. The experiments involve compaction test, Atterberg limits.18,19

Table 3: Testing Methodology for The Study

Material Type | Cement Kiln Dust (%) | Polymer (%) | Tests |

C.S | - | - | Sieve analysis, Standard Proctor Test, UCS, CBR, Direct Shear Test, LL, PL |

C.S | 5%,10%,15% | - | Sieve analysis, Standard Proctor Test, UCS, CBR, LL, PL |

C.S (89%) | Optimum value10% | 1% | Sieve analysis, SPT, UCS, CBR, Direct Shear Test, LL, PL |

C.S (88%) | Optimum value10% | 2% | Sieve analysis, SPT, UCS, CBR, Direct Shear Test, LL, PL |

C.S (87%) | Optimum value10% | 3% | Sieve analysis, SPT, UCS, CBR, Direct Shear Test, LL, PL |

Chemical Analysis of X-Ray fluorescence Contaminated Soil: Table 4 reveals results of X-Rf test conducted on soil. The lead (Pb) predominates in soil sample that comprising 73.57%. In contrast, cadmium (Cd) constitutes a lesser proportion at 52.33% compared to lead. Manganese, copper, zinc, and aluminum are detected in minimal quantities which shows that the soil is contaminated significantly.

Table 4: Heavy metal index of leachate of Wariana Dump

Traced Elements | HPI Value |

Chromium (Cr) | 13.5 |

Manganese (Mn) | 0.116 |

Iron (Fe) | 1.80 |

Nickel (Ni) | 23.66 |

Copper (Cu) | 0.072 |

Zinc (Zn) | 0.00073 |

Arsenic (As) | 2.55 |

Cadmium (Cd) | 52.33 |

Lead (Pb) | 73.57 |

Aluminum (Al) | 0.754 |

Results and Discussions

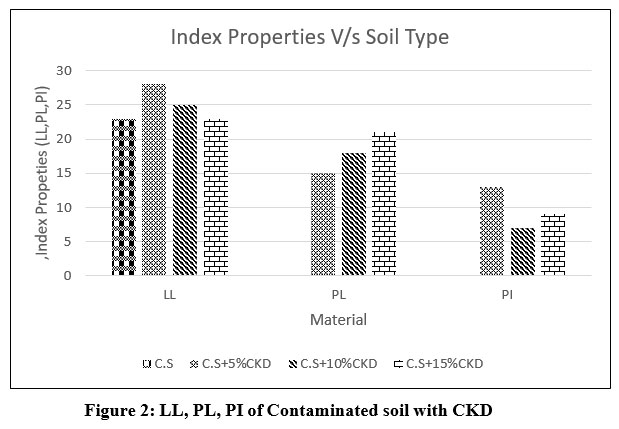

Effect on index properties

The contaminated soil can also be classified based on its plasticity through conducting liquid and plastic limit tests. The contaminated soil was non plastic while adding CKD in different proportions the soil exhibits binding properties which is critical for strength gain. The readings are mentioned below in Table 5 and Fig.2.

Table 5: Index Properties soil mix with different proportion of Cement kiln dust

Material | LL | PL | PI |

C.S | 23 | 0 | 0 |

C.S+5%CKD | 28 | 15 | 13 |

C.S+10%CKD | 25 | 18 | 7 |

| Figure 2: LL, PL, PI of Contaminated soil with CKD.

|

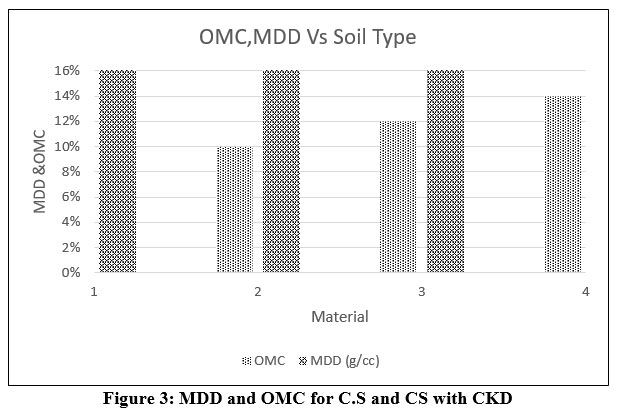

Compaction Test

The Compaction tests were done in order to have OMC and MDD of contaminated soil, mix of contaminated soil with 5%,10% and 15% of CKD. Optimum moisture content of contaminated soil is 14% and when mixed with 5% ,10% and 15% .

Table 6: Results of Standard Proctor Test

Material | OMC | MDD (g/cc) |

C.S | 14% | 1.57 |

C.S +5%CKD | 10% | 2.010 |

C.S +10%CKD | 12% | 1.97 |

C.S +15%CKD | 14% | 1.81 |

| Figure 3: MDD and OMC for C.S and CS with CKD

|

An increase in the CKD content has been noted to correlate with a reduce of the higher dry density (MDD) and an elevation in the optimal moisture content (OMC) as shown in Fig.3. The cohesion among soil particles, influencing soil firmness, may contribute to this effect by potentially reducing MDD and increasing OMC. During compaction, these cohesive particles may separate, potentially leading to an increase in MDD and a decrease in moisture content.

X-RAY Fluorescence

The comparison between X-Ray Florescence of Contaminated soil, Contaminated soil with 10% CKD, Contaminated soil with 10% CKD and Epoxy liquid polymer showed in Table 7.14

Table 7: Results of X-Ray Fluorescence of Contaminated soil with Cement kiln dust and Polymer Stabilized soil

S.NO | Elements | Contaminated Soil | Elements of Contaminate soil+ 10% CKD | Elements of Contaminate soil+ 10% CKD+ 3% POLYMER |

1 | Cr | 0.0245 | 0.0238 | 0.0148 |

2 | Mn | 0.0379 | 0.0341 | 0.0277 |

3 | Fe | 1.50 | 1.26 | 1.33 |

4 | Ni | 0.0059 | 0.0056 | 0.446 |

5 | Cu | 0.0232 | 0.0253 | 0.0201 |

6 | Zn | 0.0671 | 0.0421 | 0.0392 |

7 | As | 0.0002 | 0.0001 | <0.001 |

8 | Cd | 0 | 0.0001 | 0.00 |

9 | Pb | 0.0089 | 0.0069 | 0.0067 |

10 | Al | 3.17 | 2.76 | 2.76 |

11 | V | 0.0119 | 0.0061 | 0.0071 |

12 | Se | 0.00 | 0.00 | 0.00 |

13 | Ba | 0.0211 | 0.00 | 0.0137 |

14 | Sr | 0.0136 | 0.0088 | 0.0089 |

15 | CaO | 14.6 | 20.8 | 20 |

that the heavy metals like Cr, Mn, Fe, Ni Cu, Zn, As, Cd, Pb, Al, V, Se, Ba, Sr decreases with the mixing of Cement Kiln powder and Polymer. On comparing Contaminated soil+ 10% Cement Kiln Dust with Contaminated Soil+ 10% Cement kiln dust + 3% Polymer, the heavy metals i.e. Cr, Mn Cu, Zn, As, Cd, Pb, Al decreases whereas Fe, Ni, V, Ba, increases. CaO of contaminated soil increases with cement kiln dust and liquid polymer.

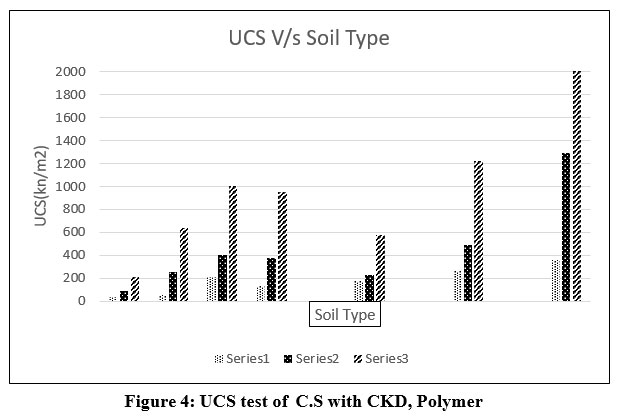

Effects on Unconfined Compressive Strength

The compressive results of treated soils with both cement kiln dust (CKD) and a blend of CKD with epoxy resin polymer are reported in Fig.4. The of addition CKD with polymer in different dosages the works as stabilizers and with curing durations. This phenomenon could be attributed to the secondary process over time, leading to the formation of pozzolanic compounds. The initial strength of contaminated soil for 28 days was 211.5 kN/m2. When 5% of Cement kiln dust (CKD) was added to soil, its strength rises to 639.72 kN/m2 whereas on addition of 10% and 15% of CKD to the contaminated soil the strength after 28 days of curing rises to 1005.27 kN/m2and 954.26 kN/m2 respectively. Optimum value of Unconfined strength was observed at 10% of Cement Kiln Dust. Similarly, when the contaminated soil with 10% of CKD was mixed with 1%,2% and 3% polymer the observed strength was 577.55, 1219.885 and 3221.825 kN/m2 respectively. The optimum value was at contaminated soil with 10% CKD and 3% polymer.10

Table 8: compressive strength values of Contaminated soil with Cement kiln dust and Polymer

Material | 7days kN/m2 | 14days kN/m2 | 28 days kN/m2 |

C.S | 34.52 | 84.60 | 211.5 |

C.S+5%CKD | 50.802 | 255.89 | 639.725 |

C.S+10%CKD | 213.366 | 402.11 | 1005.27 |

C.S+15%CKD | 132.810 | 380.904 | 954.26 |

C.S+10%CKD+1% Polymer | 177.017 | 225.023 | 577.55 |

C.S+10%CKD+2% Polymer | 258.970 | 487.954 | 1219.885 |

C.S+10%CKD+3% Polymer | 362.523 | 1288.73 | 3221.825 |

| Figure 4: UCS test of C.S with CKD, Polymer

|

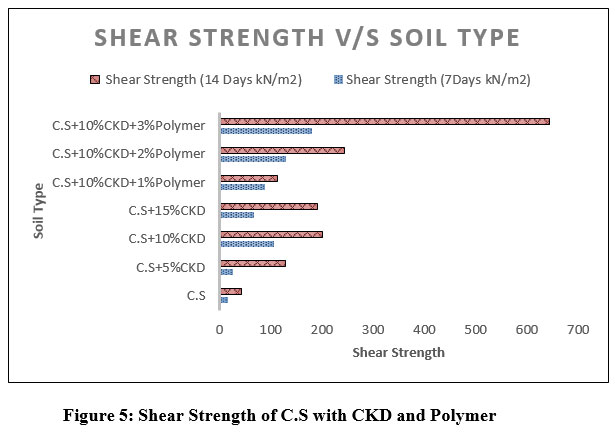

Effect on Shear Strength

Undrained shear strength done as per standards,20 demonstrate fluctuations in cohesion (Cu) concerning the proportions of (Fig. 5) cement kiln dust (CKD) and polymer in the treated soil. The Cu value shows an uptrend after the mixing of both cements kill dust and polymer. This enhancement in strength might be ascribed to the cohesive properties, gel creation, and the presence of fibers within the stabilizing agents.

Table 9: Results of Shear Strength

Materials | Shear Strength (7Days kN/m2) | Shear Strength (14 Days kN/m2) |

C.S | 17.26 | 42.3 |

C.S+5%CKD | 25.401 | 127.945 |

C.S+10%CKD | 106.83 | 201.055 |

C.S+15%CKD | 66.405 | 190.452 |

C.S+10%CKD+1%Polymer | 88.508 | 112.511 |

C.S+10%CKD+2%Polymer | 129.485 | 243.977 |

C.S+10%CKD+3%Polymer | 181.261 | 644.365 |

| Figure 5: Shear Strength of C.S with CKD and Polymer

|

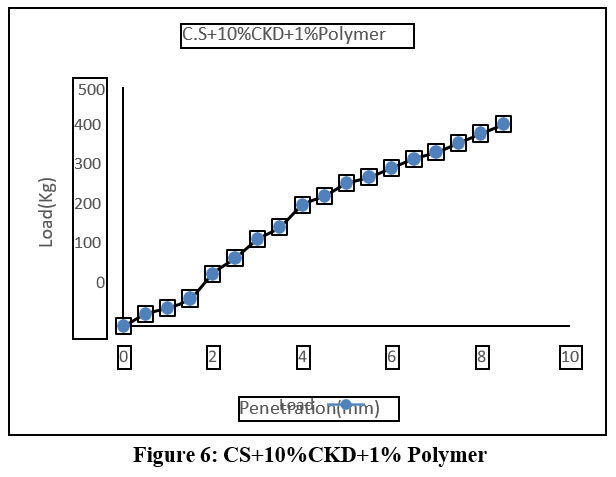

Effects on California Bearing Ratio

The California Bearing Ratio (CBR) test is a laboratory technique which determines the load-bearing capacity of a compacted soil sample under specific moisture and density conditions. The CBR value of contaminated soil was 4.102% initially which rises when 5%,10% and 15% of CKD was mixed. At 5% of CKD mix with soil the CBR value rises to 22.95%, at 10% CKD the CBR values was 42.59% and at 15% of CKD mix it was 8.173%. The optimum value was observed at Contaminated soil with 10% of Cement Kiln Dust. When the contaminated soil was mixed with 10% CKD and 1%,2%,3% liquid polymer, the CBR was 14.53%, 21.15% and 13.26% as shown in table 10 and 11 and Fig. 6 are in confirmation with past studies.

Table 10: California bearing ratio test value of Contaminated soil +(5/10/15) % Cement kiln dust

Materials | Unsoaked CBR values % |

Contaminated Soil | 4.102 |

Contaminated Soil+5% CKD | 22.95 |

Contaminated Soil+10% CKD | 42.59 |

Contaminated Soil+15% CKD | 8.173 |

Table 11: California bearing ratio value of Contaminated soil +(5/10/15) % Cement kiln dust with Polymer Percentages

Materials | Unsoaked CBR values % |

Contaminated Soil+10% CKD+1%Polymer | 14.53 |

Contaminated Soil+10% CKD+2%Polymer | 21.15 |

Contaminated Soil+10% CKD+3%Polymer | 13.26 |

| Figure 6: CS+10%CKD+1% Polymer

|

Conclusion

The main conclusion of the study is explained in this section. The addition of CKD proportions at 5%,10% and 15% contributes to the density increase from 1.57g/cc to 2.010g/cc ,1.97g/cc and 1.81g/cc respectively. The compressive strength of the stabilized soil mixture rises with higher percentages of CKD and epoxy liquid polymer.

The liquid limit, plastic limit, and plasticity index reduces for optimum dose of CKD i.e., upto10%. While, in combination with polymer and CKD, sub-grade strength in pavement improves with durability with passage of time. On other hand addition of cement in contaminated soil the optimal water content increases and maximum dry density fall. Overall, the Unconfined Compressive Strength rises when addition of cement with CKD. This is mainly due to increased cohesion of treated soil.

X-ray fluorescence data, it can be concluded that the contaminated soil treated with 10% CKD and 3% polymer, the concentrations of heavy toxic metals such as chromium (Cr), lead (Pb), and aluminum (Al) decrease in the presence of both CKD and polymer. The changes may be attributed to the interaction between CKD and polymer, which changes the chemical environment of heavy metals in the composite soil matrix. Additionally, the calcium oxide (CaO) content of the contaminated soil increases significantly with the incorporation of CKD and polymer which is good sign of removal of contaminants from soil.

The combined use of CKD and polymer may obe a promising approach for mitigating the environmental risks associated with heavy metal contamination in soils.

Acknowledgement

The authors wish to gratefully acknowledge the support of ACC Cement Plant, Himachal Pradesh, regarding Cement Kiln Dust supply. The help of Geotech laboratory staff of IKGPTU, Jalandhar, I.K. Gujral Punjab Technical University, Jalandhar is gratefully acknowledged. The authors also acknowledge the IKGPTU Managing Committee.

Funding Sources

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Conflict of Interest

The authors do not have any conflict of interest.

Data Availability Statement

This statement does not apply to this article

Ethics Statement

This research did not involve human participants, animal subjects, or any material that requires ethical approval.

Informed Consent Statement

This study did not involve human participants, and therefore, informed consent was not required.

Author Contributions

Dr. Rajiv Chauhan: Conceptualization, Supervision, Data representation, Manuscript review Drafting.

Amit Suman: Conceptualization, Data Collection, Methodology, Writing – Original Draft.

Akashdeep Singh: Writing, Editing.

References

- Abduljauwad, S.N. and Akram, T., 2007. Geotechnical behavior of oil-contaminated fine-grained soils. Geotechnical behavior of oil-contaminated fine-grained soils.

- Ahmad, S., Al-Amoudi, O. S. B., Mustafa, Y. M., Maslehuddin, M., & Al-Malack, M. H. (2020). Stabilization and solidification of oil-contaminated sandy soil using portland cement and supplementary cementitious materials. Journal of Materials in Civil Engineering, 32(8), 04020220.

CrossRef - Akinwumi, I. I., Diwa, D., & Obianigwe, N. (2014). Effects of crude oil contamination on the index properties, strength and permeability of lateritic clay. International Journal of Applied Sciences and Engineering Research, 3(4), 816- 824.

- Almajed, A., Lemboye, K., & Moghal, A. A. B. (2022). A critical review on the feasibility of synthetic polymers inclusion in enhancing the geotechnical behavior of soils. Polymers, 14(22), 5004.

CrossRef - Alpaslan, B., & Yukselen, M. A. (2002). Remediation of lead contaminated soils by stabilization/solidification. Water,Air, and Soil Pollution, 133, 253-263.

CrossRef - Al-Yaqout, A. F., & Hamoda, M. F. (2003). Evaluation of landfill leachate in arid climate—a case study, Environment international, 29(5), 593-600.

CrossRef - Ate?, A. (2013). The effect of polymer-cement stabilization on the unconfined compressive strength of liquefiable soils. International Journal of Polymer Science, 2013.

CrossRef - Awa, S. H., & Hadibarata, T. (2020). Removal of heavy metals in contaminated soil by phytoremediation mechanism: a review. Water, Air, & Soil Pollution, 231(2), 47. Environment International, 29(5), 593-600.

CrossRef - Chen, L., Nakamura, K., & Hama, T. (2023). Review on stabilization/solidification methods and mechanism of heavy metals based on OPC-based binders. Journal of Environmental management, 332, 117362.

CrossRef - Dermatas, D., & Meng, X. (2003). Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Engineering geology, 70(3-4), 377-394.

CrossRef - Dos Anjos, M.J., Lopes, R.T., De Jesus, E.F.O., Assis, J.T., Cesareo, R. and Barradas, C.A.A., 2000. Quantitative analysis of metals in soil using X-ray fluorescence. Spectrochimica Acta Part B: Atomic Spectroscopy, 55(7), pp.1189-1194.

CrossRef - Elbaz, A.A., Aboulfotoh, A.M., Dohdoh, A.M. and Wahba, A.M., 2019. Review of beneficial uses of cement kiln dust (CKD), fly ash (FA) and their mixture. J. Mater. Environ. Sci, 10(11), pp.1062-1073. Environment international, 29(5), 593-600.

- Kermani, M. and Ebadi, T., 2012. The effect of oil contamination on the geotechnical properties of fine-grained soils. Soil and Sediment Contamination. An International Journal, 21(5), pp.655-671.

CrossRef - Oluremi, J.R., Adewuyi, A.P. and Sanni, A.A., (2015). Compaction characteristics of oil contaminated residual soil. Journal of Engineering and Technology (JET), 6(2), pp.75-87.

- Paria, S., & Yuet, P. K. (2006). Solidification–stabilization of organic and inorganic contaminants using Portland cement: a literature review. Environmental reviews, 14(4), 217-255.

CrossRef - Shin, E.C. and Das, B.M., 2001. Bearing capacity of unsaturated oil-contaminated sand. International Journal of offshore and polar Engineering, 11(03).

- The California bearing ratio (CBR) as per IS 2720-31 (1990) and IS 2720-16 (1987).

- Indian Standard code the Atterberg limits test (IS: 2720 Part V - 1985).

- Indian Standard Equivalent of the Standard Proctor Test is the light compaction test (IS: 2720 Part VII - 1980).

- Indian Standard (IS) code, the method for determining soil undrained compression on strength is specified in IS 2720 (Part 11).