The Novel Approach of Oil Separator from Sea Water to Prevent Pollution in Ocean

1

Department of Automation and Robotics,

Dr. D. Y. Patil Institute of Technology,

Pimpri, Pune,

Maharashtra

India

2

Department of Mechanical Engineering,

Dr. D. Y. Patil Institute of Technology,

Pimpri, Pune,

Maharashtra

India

3

Department of Electronics and Telecommunication Engineering,

D.Y. Patil College of Engineering,

Akurdi, Pune,

Maharashtra

India

Corresponding author Email: lalitnpatil3@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.18.1.23

Copy the following to cite this article:

Patil L. N, Patil A. A, Patil S. A. The Novel Approach of Oil Separator from Sea Water to Prevent Pollution in Ocean. Curr World Environ 2023;18(1). DOI:http://dx.doi.org/10.12944/CWE.18.1.23

Copy the following to cite this URL:

Patil L. N, Patil A. A, Patil S. A. The Novel Approach of Oil Separator from Sea Water to Prevent Pollution in Ocean. Curr World Environ 2023;18(1).

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2023-01-12 |

|---|---|

| Accepted: | 2023-03-09 |

| Reviewed by: |

Norlaila Mohd Zanuri

Norlaila Mohd Zanuri

|

| Second Review by: |

Izyan Munirah Mohd Zaideen

Izyan Munirah Mohd Zaideen

|

| Final Approval by: | Dr. Gangadhar Andaluri |

Introduction

Around 300 billion gallons of oil are used globally each day. It has several applications. To create medicines, polymers, and fuel for power. Oil might leak when being transported from one location to another. Accidental spills from tankers are the sort of spill that is most frequently seen. There was an estimated 11 million gallons (37,000 tonnes) of oil leaked into the ocean as a result of the widely reported 1989 Exxon Valdez tragedy. That is the same as 125 Olympic-sized swimming pools. The leak, nevertheless, paled in comparison to the 428 million gallon Mexican Ixtoc I catastrophe, which is less well-known 1.

The majority of the remaining oil, however, comes from ordinary oil tanker activities like emptying ballast tanks and draining water from common oil consumption, accounting for just around 20% of the oil that enters the sea each year. It involves pouring into a tube. Oil must be cleared off the coast in order to lessen the environmental damage. It may set you back billions of rupees. Cleaning up after the Exxon Valdez accident is expected to cost $2.1 billion (BBC November 2002).

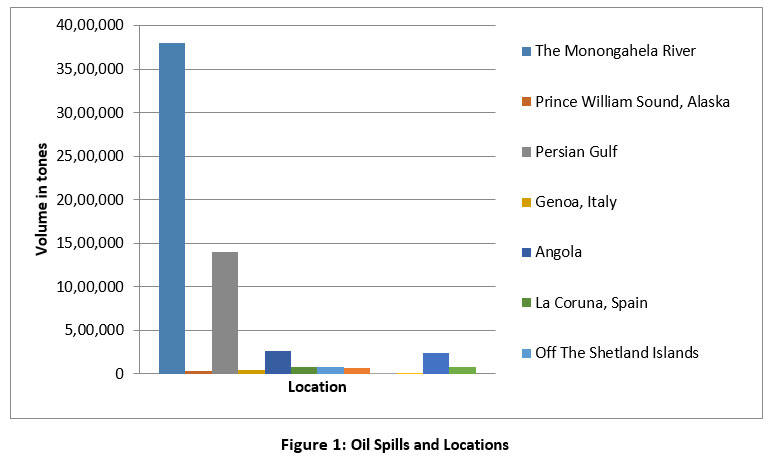

The graph below displays the number of oil spills that were reported between 1970 and 2002, showing the areas where the biggest spills had the most impact. Up to 75,000 seabirds are said to have perished as a result of the 1967 Torrey Canyon oil leak and the chemicals used to clean it up (Wildlife Trust). In contrast, a minor leak (15,000 tonnes) from the Erica in December 1999 off the coast of Brittany, France, resulted in the death of around 150,000 seabirds. Light aromatic hydrocarbons and their derivatives, which are present in oil, are referred to as oil pollutants. Aquatic species may become poisonous acutely or chronically depending on the amount of oil in the water 2.

| Figure 1: Oil Spills and Locations

|

Oil spills frequently cause both short-term and long-term environmental harm The locations and oil spills are shown in figure 1. Oil spills may leave behind environmental harm that persists for decades. Oil that has leaked from broken tankers, pipelines, or offshore rigs covers everything it comes into touch with and infiltrates the ecosystem for a long time. Every rock and sand grain is coated with oil when a huge oil spill's slick lands on a beach. Fibrous plants and grasses absorb oil when it seeps into coastal swamps, mangrove forests, or other wetlands, harming the vegetation and rendering large regions unsuitable for wildlife habitat.

Oil that has leaked from broken tankers, pipelines, or offshore rigs covers everything it comes into touch with and infiltrates the ecosystem for a long time. Every rock and sand grain is coated with oil when a huge oil spill's slick lands on a beach. When oil seeps into mangrove forests, coastal swamps, or other wetlands, fibrous plants and grasses absorb the oil, harming the plants and eventually causing part of the oil to sink to the bottom of the water, rendering the entire region unsuitable as a home for animals. It may have the same damaging effects on delicate aquatic ecosystems as it starts to sink into the marine environment, killing or infecting numerous fish and tiny animals that are important links in the global food chain. A 2007 National Oceanic and Atmospheric Administration (NOAA) investigation indicated that 26,000 gallons of oil from the Exxon Valdez oil disaster were remained in sands off the Alaskan coast despite massive cleanup efforts after the Exxon Valdez oil spill.

Practically every culture associates oil-covered birds with the environmental harm caused by oil spills. Sea birds are doomed by any oil leak in the water. Some shorebird species may relocate if they recognise the threat in time, but seabirds that swim and dive for food will undoubtedly be doused with oil. Additionally, breeding sites are harmed by oil spills, which may have detrimental long-term consequences on entire species. The long-term environmental effects of the 2010 BP Deep-water Horizon offshore oil leak in the Gulf of Mexico, for instance, won't be understood for several years. That spill happened during the peak mating and nesting season for many bird and marine species.

Marine creatures including whales, dolphins, seals, and sea otters regularly perish in oil spills. The lethal injury might appear in a variety of ways. Sometimes, the oil jams the blow holes of whales and dolphins, preventing the animals from breathing normally and interfering with their ability to communicate. Otters and seals are susceptible to hypothermia because of the oil that covers their fur.

Fish, crustaceans, and other marine life are frequently killed by oil spills, especially when huge quantities of fish eggs and larvae are exposed to the oil. One of the first casualties of the 2010 BP Deepwater Horizon offshore oil leak, along with billions of salmon and herring eggs lost in the Exxon Valdez oil spill, was the Louisiana coastal shrimp and oyster fishery. These fisheries still need time to recover.

One of the most prevalent environmental effects of oil spills is the long-term harm to numerous species and the habitats and nesting or breeding places that these species depend on for existence. Even many animals that live mostly at water, like different types of sea turtles, must come onshore to lay their eggs. The oil that sea turtles come into contact with in the water or on the beach where they lay their eggs can hurt the turtles, and the oil can also affect the eggs and cause them to hatch improperly.

Literature Review

The complexity of treating water has substantially grown, especially with waste water comprising immiscible organic solvents and water combination. Therefore, there is a great deal of interest in finding a practical water purifying method that uses little money and energy to solve the problem 3. Clean water is essential for both human existence and industrial productivity, but in recent years, its scarcity has emerged as one of the major worldwide issues posing a danger to human survival 4. According to reports, the lack of fresh water has become one of the most serious issues facing our world, causing 10,000 deaths on average every day and thousands of other people to suffer 5. Researchers want to lessen this hazard by using seawater desalination technology to acquire pure freshwater from the most water-rich oceans. One of the most effective, sustainable, and ecologically beneficial methods of desalination is water evaporation powered by solar energy. Salinity management, water evaporator recovery, and oil contamination of saltwater all remain difficult tasks6.

An oil spill occurs when liquid petroleum products are unintentionally released into nearby waterways, most often the ocean. With an estimated 11,000,000 US barrels of oil spilled (1,300,000 m3), the Kuwait oil fires of 1991 were one of the greatest oil disasters in human history7. The most contentious topic is marine oil spill cleanup and management because of how difficult it is to clean up. As a result, it's crucial to use a variety of cleanup techniques to combat the threat they might cause to the marine ecology 7. Depending on the technique of processing, oil can be treated in open water at varying speeds. The quickest methods include airborne dispersants, skimming, and in-situ burning.

For various situations, different oil spill remediation materials and techniques are appropriate. Bio-based materials need to be thoroughly studied for the successful and sustainable remediation of oil spills, as it is doubtful that one material will be appropriate for all conceivable oil spill scenarios. Local rules should also be taken into account when designing a technique since they have an impact on the economics of materials8. Thermal or in-situ burning techniques were only utilised when an oil spill happened in open water, such as a sizable area on the saltwater surface, snow, or ice, because the release of several pollutants into the air and marine environment jeopardised marine life, human life, and other resources. The degree of pollution from thermal or in-situ burning techniques was extremely high 9(p1)

There have been significant oil spills into the water that have had a significant negative influence on the ecosystem. In addition to this, occasionally oil spills occur as a result of long-standing, negligent practises in the usage of oil industries and oil products 10. Oil spills have a negative impact on marine life and the ecosystem 11.

Some researchers record the presence of MPs at all evaluated sample sites and aims to analyse the status of MPs in surface waters off Kerala's north shore, on India's southwest coast 12. Oil spills in the maritime environment pose a tremendous threat to marine life, severely damage coastal ecosystems, and contaminate beaches, estuaries, coral reefs, and mangroves 13. The majority of petrochemical as well as manufacturing sectors produce waste water that contains oils; so many countries have established strict safety standards for this type of waste accumulation of water. As a result, these industries are required to have oil skimmers/Skimmers to isolate the oils out from polluted water.

Objective and Novelty of Study

To the author's knowledge, no research has ever been done on the separation of oil from sea water, specifically utilising an aluminium disc. The novelty of the present work is to design and develop the novel oil separator from sea water.

Materials and methods

An oil collector can be used to collect oil as shown in figure 2. Further, the components used in the development of model are given in Table 1. Oil will float to the top because water is heavier than oil. That is the cause of the current gulf oil leak that you can see on the ocean. When water and oil are combined in a container with a bottom drain, the oil will float to the top, allowing the water to be drained from the bottom. Numerous huge marine oil spills up to the present have had devastating effects on the maritime and coastal ecology, followed by financial catastrophes for the local fishing sector and tourists.

Methodology

Table 1: Components used in oil Collector

S.N. | Component | Specifications |

1 | Battery | 12v/2.5ah |

2 | Motor | 12v/10rpm |

3 | Motor 2 | 12v/18000rpm |

4 | Aluminium Plate | Dia. - 20 Cm (4 Plates) |

5 | Shaft | 20 mm dia |

6 | Acrylic Body | Length - 57 cm= 0.57 m Breadth - 41 cm= 0.41m Height - 13.50cm= 0.135m |

7 | Electric Switch |

|

| Figure 2: Model of Oil Separator.

|

Design Criteria

By assuming following dimensions of

Acrylic body

Length - 57 cm= 0.57 m

Breadth - 41 cm= 0.41m

Height - 13.50cm= 0.135m

Disc

Diameter - 20cm= 0.2m

Hole dia. - 0.5 cm= 0.005m

Thickness - 0.1cm= 0.001m

Tank

Diameter - 100cm= 1m

Height - 45cm= 0.45m

Water level in tank - 35cm= 0.35m

Calculations:-

Weight of body in water:

W= Y * V [7]

Where ,

V = volume of material, m3

Y = sp. Weight or weight density, KN/m3

27% of volume of body submerged in water,

= 9.81 *(0.27 * V)

= 9.81 * (0.27 * ( 0.57 * 0.41* 0.135))

= 0.0835 KN

= 83.56 N

: W = 83.56/9.81 = 8.51 kg.

Buoyancy force

By Archimede’s principle,

BF= P * g * V [7]

Where,

P = density of sea water.

V = volume

=1010 * 9.81 * (0.57 * 0.14 * 0.135)

=312.59 N

Center of buoyancy:

P (acrylic)= 1050- 1200 kg/ m3

: Y = P * g [7]

= 1075 * 9.81

= 10545.75 N/m3

= 10.54 KN/m3

Weight of body = volume * Y (acrylic)

= 0.57 * 0.41 * 0.135 * 10.54

=0.332 KN

By Archimedes principle,

Weight of body= weight of liquid displaced

: V = 0.332/9.81 = 0.0338 m3

V = 0.0338 m3

Let ,

h = height of body,

Volume of liquid displaced= L * b * h

0.0338 = 0.57 * 0.41 * h

: h = 0.144m

: Centre of buoyancy = h/2 = 0.144/2 = 0.072m

Weight of body= volume of liquid displaced

= Y * A * h

332 = 980 * (0.57 * 0.41) * h

: h = 0.144m = 14.49cm

Before the immersion, liquid level is 35cm deep.

: The collector floats at level = 35-14.49 = 20.51c m

: The collector floats at 20.51cm from the bottom of tank.

Simple Payback Period (SPP) :-

(Assuming Oil Separator runs only 7hrs./day)

SPP = First Cost / (Benefits Per Day – Daily Operating Cost)

: SPP = 6270 / (3000 – 500 )

: SPP = 2.5 Days ( Without using Solar Cells )

SPP = First Cost / (Benefits Per Day – Daily Operating Cost)

SPP = 6270 / (3000 – 0 )

SPP = 2 Days ( With using Solar Cells )

Forces Acting on Oil Collector

The collector is subject to several forces as it flows through the water. There are many more, but these are only a sample. The force pulling on the vessel itself is called drag. The boat's bottom experiences drag as it goes through the water, slowing it down. When the sail shares the wind coming from the boat's windward side, lift is produced. The pressure differential between the sail's leeward and windward sides produces lift. In reality, buoyancy is the pressure differential that drives you forward. A ship's buoyancy is its capacity to float while immersed in water.

Balanced forces

We refer to two forces as balanced forces when they exert an equal amount of force on an object while operating in opposing directions.

This is what occurs when an item is subject to equal and opposite forces, or when no forces are present at all: When something isn't moving, it stays static and a moving object keeps going in the same direction and at the same speed. So take note that an object can move even when no forces are exerting any force on it.

Working of Seperator

Getting oil out of saltwater may be a difficult operation. Because oil has a lower specific gravity (0.79 to 0.84) than saltwater (1.023 to 1.028), it floats on top of it, making "skimming" one of the more successful "immediate" methods of removing crude oil from seawater. Other ways have been devised, such as employing a dispersant to sink the oil, introducing "oil-eating" bacteria, and just allowing the oil to degrade naturally.

| Figure 3: Model of Oil Collector

|

Our studies major goal is to rescue marine life without causing pollution. This is a fairly straightforward idea. This study uses four aluminium discs connected to a motor shaft that is driven by a 12V DC battery as shown in figure 3. For example, one of the most common methods used is burning all the oil spilled on the surface of water. Because of this, a high amount of toxic gases, such as Carbon Monoxide (CO), Carbon Dioxide (CO2), and other gases mix with the air and have an adverse effect on marine life. Earlier oil collection techniques were inefficient and extremely hazardous to the environment. Our development does not produce any pollution and collects between 85% and 90% oil with only a little amount of water. This oil may then be recycled.

| Figure 4: Model of Oil Collector.

|

| Figure 5: Model of Oil Collector.

|

| Figure 6: Model of Oil Collector.

|

Discussions

In this work, it was intended to design and develop the oil separator model. The proposed model will be gainful while collecting the spill oil spread over the surface of sea. The current best available techniques (BAT) schematic for preventing and containing oil spills was created from existing worldwide literature and the technical expertise of the Italian Ministry of Environment's Nature Conservation Agency. Other new methodologies are now being considered, which may lead to a further examination of the given BAT schematization and future enhancements 14.

Some researchers introduced eco-friendly oil collector for separating and collecting oil from water. A superhydrophobic fabric bag was filled with lipophilic hydrophobic kapok fibres to create the collector. Superhydrophobic textiles were created using a simple, low-cost, and scalable one-step dipping method that demonstrated high oil/water separation efficiency for a variety of oil/water mixes with varying oil-to-water volume ratios. Because of the fabric's superhydrophobicity, the collectors generated may absorb varying levels of oil from water into the pores of the kapok fibre aggregates while rejecting water entirely. In addition, the collector has a large sorption capacity, a quick sorption rate, and strong recyclability 15.

Over the last two decades, the remediation of oil contamination in seawater has attracted worldwide attention. Circular pipes were employed as a mechanical technique to clean up oil spills in saltwater under varied variables of temperature, oil gravity, shaking frequency, pipe diameter, and starting reservoir thickness. To carry out the research, an experimental model was devised and built 16. In the event of an oil leak, some articles discuss the recovery and separation of crude oil from sea water. It is based on the theory of oil-contaminated water absorption by textile media, followed by extraction and separation of oil from sea water. For this goal, many textile composites are used, and the best fibre combination is discovered. The machinery and procedure for recovering oil are examined 17.

Developing nations like Ethiopia and Yemen struggle with issues including congested transportation, unregulated pollution, and population growth 18. Therefore, the research carried out will be the suitable solution to enhance the atmospheric conditions and reduce the pollutions.

Discussions

According to the results of the present study, this mode can help us lessen marine and air pollution as well as the expense of oil collecting. The effectiveness of oil collection can be improved. As it will not harm the environment, the initiative is environmentally friendly. Compared to other approaches, we can employ this separator with optimum efficiency at a reasonable cost. It can remove between 85 and 90 percent of the oil from seawater. Therefore, it may be concluded that oil recovery rate is significant if the oil separator model adopted for sea pollution control over oil spread.

Acknowledgment

The authors would like to thank Dr. L. K. Wadhwa (Principal) and Dr. Pramod D. Patil (Research Dean) for their constant support and motivation during the research.

Conflict of Interest

There is no conflict of interest.

Funding sources

There is no funding or financial support for this research work.

References

- Graham P. Deep sea oil spill cleanup techniques: Applicability, trade-offs and advantages. Proquest Discovery Guides. Published online 2010.

- Yan Z, Pan J, Gao F, et al. Seawater quality criteria derivation and ecological risk assessment for oil pollution in China. Marine Pollution Bulletin. 2019;142:25-30. doi:10.1016/j.marpolbul.2019.02.033

CrossRef - Chen S, Liu Y, Wang Y, et al. Dual-functional superwettable nano-structured membrane: From ultra-effective separation of oil-water emulsion to seawater desalination. Chemical Engineering Journal. 2021;411:128042. doi:10.1016/j.cej.2020.128042

CrossRef - Guo C, Zhao J, Zhang T. Development of a modified composite structure from polyurethane sponge for desalinating seawater polluted by oil. Desalination. 2022;524:115471. doi:10.1016/j.desal.2021.115471

CrossRef - Al Hashar N, Anisuddin S, Sadik T, Tahseen S. Oil spill pollution in seawater — a hindrance for desalination. Desalination. 2004;166:305. doi:10.1016/j.desal.2004.06.085

CrossRef - Yang Z, Yang D, Yang C, et al. Magnetically recyclable 3D water evaporator for desalination and purification of oil-contaminated seawater. Desalination. 2023;546:116187. doi:10.1016/j.desal.2022.116187

CrossRef - Malhas R, Al-Ibrahim Y, Al-Meraj A, Abdullah H, Alshatti A. Application of magnetic separation for oil spill remediation and recovery in Kuwait sea water. DWT. 2021;209:114-120. doi:10.5004/dwt.2021.26498

CrossRef - Doshi B, Sillanpää M, Kalliola S. A review of bio-based materials for oil spill treatment. Water Research. 2018;135:262-277. doi:10.1016/j.watres.2018.02.034

CrossRef - Hoang AT, Pham VV, Nguyen DN. A Report of Oil Spill Recovery Technologies. 2018;13(7).

- Pawar SH, Kumar SA, Vishu A, Yashodhan P, Mayuresh P. Design and fabrication of Oil Collector. 1(3).

- Fokina NN, Bakhmet IN, Shklyarevich GA, Nemova NN. Effect of seawater desalination and oil pollution on the lipid composition of blue mussels Mytilus edulis L. from the White Sea. Ecotoxicology and Environmental Safety. 2014;110:103-109. doi:10.1016/j.ecoenv.2014.08.010

CrossRef - Anu Pavithran V. Study on microplastic pollution in the coastal seawaters of selected regions along the northern coast of Kerala, southwest coast of India. Journal of Sea Research. 2021;173:102060. doi:10.1016/j.seares.2021.102060

CrossRef - Nukapothula S, Wu J, Chen C, Ali P Y. Potential impact of the extensive oil spill on primary productivity in the Red Sea waters. Continental Shelf Research. 2021;222:104437. doi:10.1016/j.csr.2021.104437

CrossRef - Cumo F, Gugliermetti F, Guidi G. Best available techniques for oil spill containment and clean-up in the Mediterranean Sea. In: Water Resources Management IV. Vol I. WIT Press; 2007:527-535. doi:10.2495/WRM070491

CrossRef - Wang J, Wang H. Eco-friendly construction of oil collector with superhydrophobic coating for efficient oil layer sorption and oil-in-water emulsion separation. Surface and Coatings Technology. 2018;350:234-244. doi:10.1016/j.surfcoat.2018.07.016

CrossRef - Shedid SA, Abou-Kassem JH, Zekri AY. Mechanical Cleaning of Oil Spills in Seawater Using Circular Conduits. Energy Sources. 2005;27(13):1257-1268. doi:10.1080/009083190519366

CrossRef - Nandagopal KR, Kumar MP. Oil Contaminated Sea Water Recovery System Using Composite Textile Absorption Media. International Journal of Engineering Research. 2016;5(4):311-314.

- Lalit N. Patil, Hrishikesh P. Khairnar, J. A. Hole, et al. An Experimental Investigation of Wear Particles Emission and Noise Level from Smart Braking System. Evergreen. 2022;9(3):711-720. doi:10.5109/4843103

CrossRef