Achieving Sustainability through Zero Waste Fashion-A Review

1

Apparel and Textile Science Department,

PAU,

Ludhiana,

India

Corresponding author Email: lotikagupta1975@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.15.2.02

Fashion industry encompasses every stage of production, starting from production of fibres, fabric, designing, production and sale of garments. Fashion industry holds second place among the pollution causing industries. This industry has an enormous impact on the environment as well as on the millions of people working in it. During the course of production of garments, a substantial amount of waste is generated. Solid waste, thus produced is sent to landfills, where it decomposes and leads to production of methane gas. Methane is a powerful greenhouse gas that traps atmospheric heat more effectively than the most common greenhouse gas—carbon dioxide. The solid waste contributes significantly to the existing problem of global warming. The increase in population and increased consumption of products in the developed world has started the global waste problem. Fast fashion provides the marketplace with affordable apparel. Fashion magazines create the desire for new “must-haves” for each season. But fast fashion has its side effects in the form of pollution footprint. The rate at which the clothing waste is generated is far more than its rate of decomposition. Millions of tons of clothing waste is dumped in landfills, which may take between one to five months to fully biodegrade, with the condition that the waste comprises only of organic cotton fabrics. The waste generated is a mixture of natural as well as synthetic fibre, with 20 to 200 years of decomposition time. Each chemical treatment elongates its biodegradation time. A viable solution to this problem may be the adoption of every technique resulting in lower waste generation. Zero waste Fashion may be a step towards achievement of sustainability. A Zero waste policy must be adopted to identify inefficiencies in the use of inputs like raw materials, power and workforce. Zero waste policy supports every phase of the sustainability movement. This paper is centered on the main causes of waste generation in garment industry and the Zero waste generation techniques of garment production and other means of waste reduction which can be adopted to make the fashion industry sustainable.

Copy the following to cite this article:

Gupta L, Saini H. K. Achieving Sustainability through Zero Waste Fashion-A Review . Curr World Environ 2020; 15(2).

DOI:http://dx.doi.org/10.12944/CWE.15.2.02Copy the following to cite this URL:

Gupta L, Saini H. K. Achieving Sustainability through Zero Waste Fashion-A Review . Curr World Environ 2020; 15(2). Available from: https://bit.ly/3eCsDyl

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2020-02-07 |

|---|---|

| Accepted: | 2020-05-29 |

| Reviewed by: |

Eric Danso Boateng

Eric Danso Boateng

|

| Second Review by: |

Nuralam Hossain

Nuralam Hossain

|

| Final Approval by: | Dr Gopal Krishan |

Introduction

Clothing is an integral part of human society. It not only maintains the basic need of protecting humans from outside environment to maintain essential conditions for survival but also a means of expressing identity, wealth, power etc. In addition, clothing has been an important commodity traded globally over centuries.1 Fashion is a popular aesthetic expression in clothing at a particular time. Earlier, most of the clothing was made to order according to the requirements of the customer. With the advent of industrialization, people quickly adopted new devices such as the sewing machine. Mass-production of clothing started. Garment industry includes every aspect of the garment, right from production of fibres and fabric, the production of garments through fashion industry to fashion retailers up to the consumer. Apparel manufacturing involves a number of stages like product design, selection and inspection of fabric, patternmaking, grading, marking, cutting, sewing, finishing, dyeing, printing, washing, quality control etc.

During each stage of garment manufacturing, a considerable amount of waste is generated. The raw materials are used in various combinations. Different processes are carried out on the raw materials during production and are changed to finished goods. The refuse left out after every process creates waste.2

Industrialization leads to easy availability of cheaper goods to the consumers, which is a primary part of the economy. Constant marketing of new products leads to buying of new clothes and discarding of old ones which are thrown away just because they look obsolete as soon as new styles come in vogue. So, as soon as the new fashion comes, old clothes become out of fashion, and the time taken by a product to travel from a showroom to landfill becomes short.3

Fashion holds second place among the polluting industries and has a huge impact on the environment as well as on the millions of people working in it. According to the United Nations Organization the fashion industry has to change its policies, otherwise, by 2030 clean water will not be available to half of the world’s population. According to a survey, Americans discard 13 million tons of textiles each year which accounts for about 9 percent of the non-recycled waste.4

Textile wastes can be divided into three categories:

Pre-consumer (Production), Post Consumer and Industrial Waste

Pre-consumer textile waste is the waste generated during manufacturing process of apparels. This type of waste includes cut-offs, selvages, shearing, rejected materials, B-grade garments, overestimated fabric and off-cuts of saleable size called “cabbage”. This type of textile waste is generally “clean waste”.2 The quantity of yarn, excess trims, defected fabric and dead stock which are not used in production is huge.3

Post-consumer textile waste consists of all types of worn out, spoiled, outgrown, or no longer in fashion garments or household textiles (e.g. sheets or towels) that the consumer does not need and decides to throw away. The discarded garments are of medium to good quality that can be recycled by someone else.

Industrial textile waste is generated during commercial and industrial applications of textiles. This includes hospital waste and textiles used in industrial applications such as filtration, conveyor belting, etc. Industrial waste is generally “dirty waste”.5, 2

Reasons for Wastage

Mainly the wastage takes place due to inefficient, out of date and conventional technologies, lack of technical skills, lack of quality awareness, designing mistakes communication gaps, fabric faults, etc.

The chief constituent of garment industry solid waste is cloth. Millions of tons of clothing waste are dumped in landfills, which may take between one to five months to fully biodegrade, with the condition that the waste comprises only of organic cotton fabrics. The waste generated is a mixture of natural as well as synthetic fibre materials, with 20 to 200 years of decomposition time. Each chemical treatment elongates its biodegradation time6. Garment industry waste contains carbon and is prone to chemical reactions due to its composition and heat generated by microbial activity during decomposition. Most apparel units do not have appropriate solid waste disposal facilities in the factory or in the surrounding area. Waste is either subjected to open burning in the factory premises or it is transported to landfills or dump sites. Such makeshift disposal methods result in serious environmental impacts. Open burning would result in air pollution due to smoke and soot as well as the possible release of carcinogenic compounds from plastic burning. Open dumping would result in aesthetic problems as well as possible ground and surface water contamination.7, 8 Waste is a major cause of global warming. Solid waste landfills are major source of methane gas. Methane is a greenhouse gas that traps atmospheric heat 23 times more than carbon dioxide which is the most abundant greenhouse gas.4

Fast fashion provides affordable apparel. Fashion magazines create the desire for new “must-haves” for each season. However, fast fashion has its pollution footprint. Every step of the life cycle of clothing has latent environmental as well as occupational hazards. Indiscriminate disposal and discharge of waste materials, contaminates the soil. The contamination gets carried down due to gravitation. Therefore, waste collection areas become sites of uncontrolled chemical reactions and these unrestrained piles of waste materials become prospective explosives.3

Increase in population and high rate of consumption of fashion products in the developed countries has led to global waste crisis. Affluence has created effluence. Scientists believe that so much waste is being generated at such a high rate which cannot be absorbed by the environment. Due to the extreme negative effects of waste generation, it is imperative to find ways to reduce waste. Reduction of waste in every stage of production is the dire need of present times. In addition to the reduction in pollution, the waste reduction efforts would result in saving of resources and energy and increased efficiency of production.9

Textile Waste Management

The 4R principle of waste management is also applicable to apparel and textile wastes.10 This includes:

- Reduce

- Replace

- Reuse

- Recycle

A) Waste Reduction Methods

- With the help of computer aided designing, wastes in the cutting room can be reduced.

- Care in movement of work-in-progress

- Quality Control

- Least make break/rework

- Avoid bad quality reworks

- Optimization of usage of materials

- Enhance labor productivity through skill training

- Efficient Management Information System (MIS) for timely decision making 11

B) Zero-Waste Design

In Zero Waste design the pieces of pattern of a design are fitted together in such a way that no fabric is wasted during the cutting. In this design, spaces between the pattern pieces are eliminated. Pattern pieces are designed in the fashion of interlocking puzzle like, or using up leftover pieces of fabric artistically to make embellishments, bias tape, and the like is the essence of this technique. International fashion designers such as Julian Roberts, Mark Liu, Holly McQuillan, Yeohlee Teng and Timo Rissanen are already using this concept12. Zero-waste techniques often result in creation of exclusive garments that adjust themselves to the nature and size of the initial fabric. Traditional garments like Indian saree, Japanese kimono and African kangas and kitenges are examples of zero waste design.

Zero Waste Fashion Techniques

These refer to all those methods that can be used to remove fabric wastage from apparel manufacturing using specific designing techniques. Apparels produced through zero – waste fashion design methods consume only the amount of fabric needed for a particular piece of garment and leaves almost no fabric waste. Broadly speaking, zero waste fashion concept refers to a system where waste is reduced to almost nil in every stage of designing, production and usage stage of a garment.13, 14

There are a number of ways to achieve zero-waste fashion design:

1) Planned Chaos 2) Geo Cut 3) Cut and Drape 4) Reusing of scraps of cloth and yarns.15, 16, 17

1) Planned Chaos

In this method, garment pattern blocks formed in a traditional fashion are combined so that they form the basic shape of the garment and all pieces are unified. This technique requires deep understanding of the rules of tradition pattern cutting, but these rules are manipulated in such a way that the wastage is reduced to minimum. There are two ways of pattern cutting: Jigsaw cutting, Subtraction cutting.18

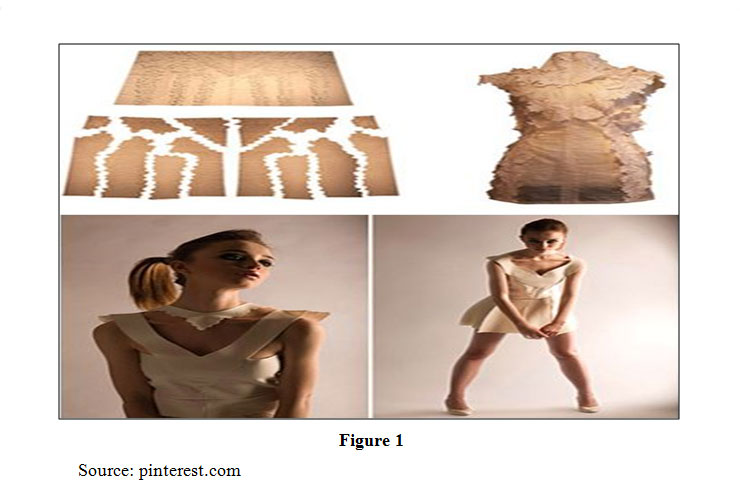

This method results in elimination of waste by cutting small components (pockets- collar- trims….) from a single piece of fabric and fit all the pieces together like a puzzle in a way that each bit of fabric is utilized, while resulting in a beautiful garment. This technique is an eco-friendly technique that has been completely over looked in the industry.19

|

Figure 1 Click here to View Figure |

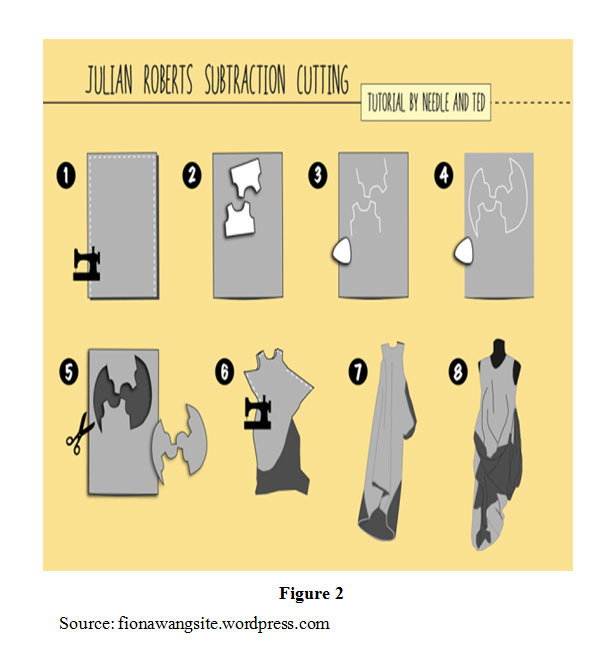

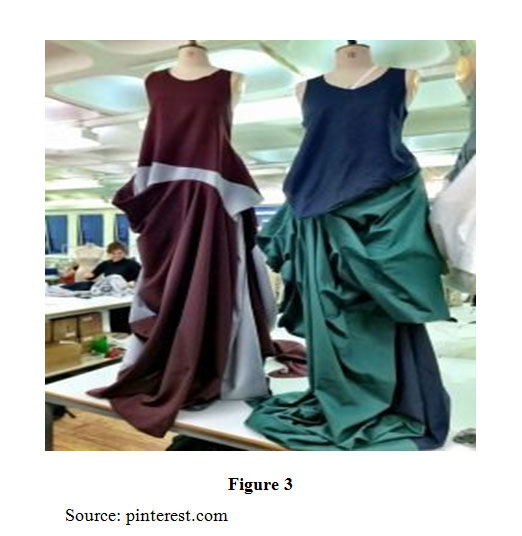

b) Subtraction Cutting

In this technique, the pattern is cut not to show the outer shapes but the pattern represents the negative spaces in the garment. In this process, garment is constructed from enormous sheets of cloth with bizarre shaped holes through which the body passes.20

|

Figure 2 Click here to View Figure |

|

Figure 3 Click here to View Figure |

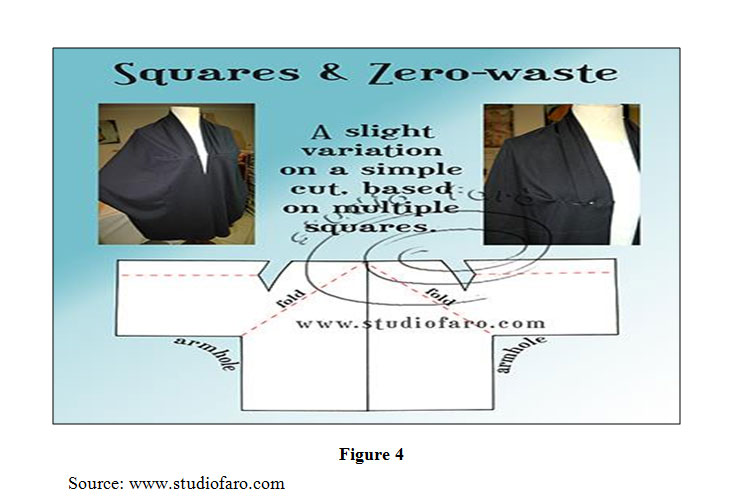

2) Zero – Waste Cutting Technique "Geo Cut"

In this method, the use of pattern pieces cut in geometrical shapes for instance squares, triangles and circles is made. This method has been used in history, for example, kimono designs.18, 21

|

Figure 4 Click here to View Figure |

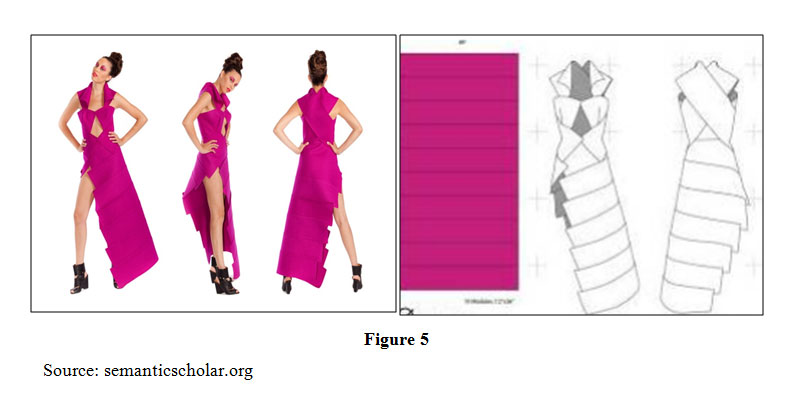

3) Cut and Drape

The variety of techniques such as cutting, draping, folding, steam molding and machine and hand – stitching are used to form the garment.18 In this a fashion designer can play with the manner fabric drapes to form new designs.

|

Figure 5 Click here to View Figure |

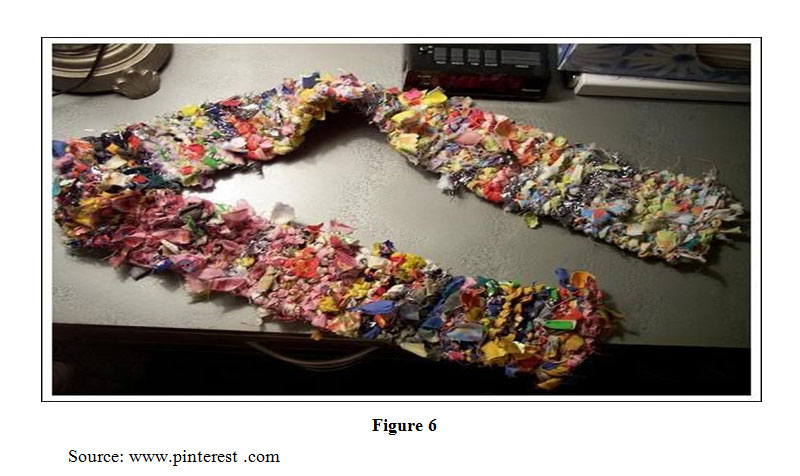

4) Re using Scraps of Cloth and Yarns

This method deals with off cuts or leftover material after the process of product manufacturing is finished and there are diverse ways to reuse scraps.

Fabric is created by using leftover yarn from knitting factories then knit the yarns directly in the shape of the garment in a way that the resultant garment is completely seamless. No further cut – offs or leftovers are there.22

|

Figure 6 Click here to View Figure |

b) Pleating

The rectangular pieces of textile waste scraps are pleated and shaped into a garment22.

|

Figure 7 Click here to View Figure |

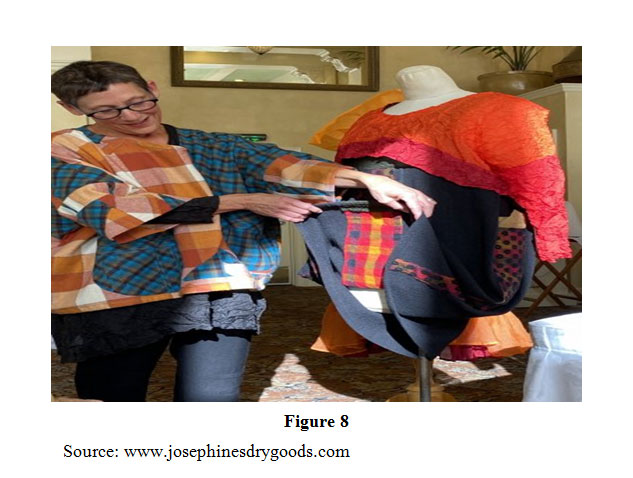

c) Draping Scraps of Fabric

The designer can drape scrapes of fabric on the dress form in order to create new designs. Gathers, pleats, darts and the bias can be used to create shape of the garment, without cutting off and wasting the fabric.4

|

Figure 8 Click here to View Figure |

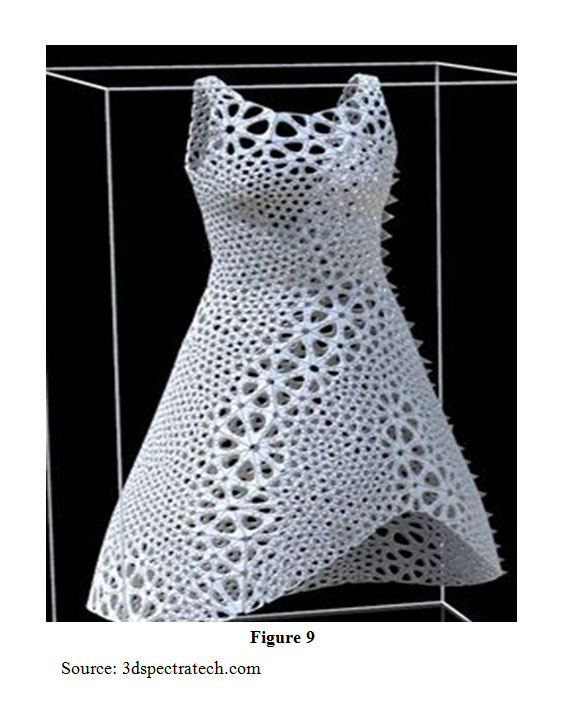

Replacing the old cut and sew technology with new No-Waste or less waste technologies, which includes

a) 3D PrintingOf clothes at large scales can lead to zero-waste production. 3D printing also known as additive manufacturing is the process of manufacture of three dimensional solid objects using a digital file. Successive layers of material are piled up in an additive process until the object is created23.

|

Figure 9 Click here to View Figure |

b) Direct Pattern on Loom (DPOL)

Generally, rectangles of fabric are woven and then cut; DPOL computers weave fabric in the required pattern shape, thereby eliminating waste creation. Brand, “August” has reduced fabric wastage by 15%, and also saves on energy, labour, time and use of chemical using this technique.

c) Seamless Knitting

Is an old technique where the yarn is knit into finished garments. This method does not involve cutting of fabric and thus reduces generation of waste. Sportswear, knitwear, undergarments and safety gear are generally produced using seamless knitting.24 Seamless knitting technique is being used in Nike’s Flyknit technology and Adidas’ Adizero Primeknit.

Garments or household textiles (e.g. sheets or towels) can be sold or gifted to another user. Many times garments are discarded just because they develop a hole or they are torn. This kind of clothes should be mended and worn or these should be given to less fortunate ones. Out of the textile waste collected by the charities, sixty per cent are items of clothing that can be worn again or reused and 15% can used as industrial wipe cloths.10 A segment of clothing may be resold to other consumers at a lower price or these may be exported to developing countries in bulk for sale.3

Efforts are being made in India by different organizations to treat the pre-consumer textile waste. Refined cotton comber and card waste, yarn waste and hosiery waste is exported from India to other countries like England, Malaysia, Thailand, China, Hong Kong, Singapore etc. Small traders use the silk waste for manufacture of different products like bangles, scarves, tassels, silk embroidery yarn, Christmas decors, etc.25 Panipat, in Haryana, India, is the largest post consumer textile recycling center, where they import used winter clothing to form “shoddy” wool yarns and blankets.26

Obstacles in Recycling

Lack of Equipments

Often recycling results in very short fibres that requires special machinery to spin into yarns. Moreover while recycling blends such as polyester and cotton, or cotton and lycra, separate fibres cannot be recovered easily.

Lack of Consumer Awareness

Lack of awareness towards waste issues amongst public, also acts like hurdle in recycling. Recovery of post-consumer textile waste depends on donations from the public. Increased recovery of material for recycling along with increased acceptability of recycled products, can be achieved only by an educated public.

Cost of the End Product

Recycling of the textile waste is a labour intensive process. It is difficult for recycled fibers to compete in the markets when the price of virgin fibre is so low.27

Lean Manufacturing

Lean manufacturing eliminates waste in each area of manufacture including product design, supplier networks, factory management and customer relations. Its goal is to reduce human effort, inventory, time to develop products, and space in order to become extremely quick to respond to customer demand while producing top value products in the most well-organized and economical manner.28 Various Lean techniques are29

|

Value stream mapping |

Takt time |

EPEI |

|

Leveling (Heijunka) |

Pull Systems |

Single Minute Exchange of Dies or SMED |

|

Poka-yoke |

Kanban |

JIT (JUST IN TIME) |

|

5S Five S [Seiri (sort) Seiton (set in order) Seiso (shine) Seiketsu (standardize) Shitsuke (sustain)] |

||

In this direction, many leading brands are trying to acclimatize to this society consciousness that needs them to embrace environmental and social responsibility by adopting new ways of production that are not so detrimental to the environment. To address this issue, companies have started to integrate sustainability in the fashion life cycle of products throughout their process of development.30

Conclusion

A Zero waste strategy must be embraced to eliminate inefficiencies in the use of materials, energy and human resources. High quality supplies should be accepted so that apparel companies are able to achieve proficient and quicker production with minimization of wastage. The left over materials after production used should be carefully sorted during production. Proper disposal of the wastes should be planned. Different accessories are used while the transformation of fabric into a garment. Any garment can be called environmentally friendly, only if each piece of the garment fulfills environmental requirements. Special efforts should be made to make eco-friendly accessories like buttons, zippers, buckles, leather accessories, adhesives and hooks so that they are better suited to environment.10

Stringent rules and regulations need to be introduced and implemented. In addition to this, improved consumer consciousness about less toxic and sustainable products, may transform the apparel industry. However, the biggest responsibility for increasing sustainability in the clothing industry lies with the consumer. Using garments for a longer span of time, buying lesser clothing and long-lasting garments, and recycling these garments would lead to increased sustainability.3

To achieve a sustainable future, great competence in the use of all the resources will have to be exercised so that the needs of each and everyone are fulfilled.8 Waste reduction can be practiced not only in garment manufacturing, but also in textile processing operations, especially wet processing. Chemicals used for textile processing can be replaced with more sustainable technologies. Such a study can be conducted in future to carefully monitor all the processes in textile units and methods can be thought of to reduce the amount of waste contributed by the textile unit. Zero Waste is a whole-system approach that aims to eliminate rather than manage waste.31Sustainability is the solution to run a trade in the modern times, especially if the company is exporting its products to other companies. Discarded waste fabrics can act as a new resource and a wealth potential.32

Acknowledgement

I am thankful to my Research Guide Dr (Mrs) Harminder Kaur Saini for her valuable support. I am also thankful to the editor of the journal and the reviewers for their constructive suggestions during the course of manuscript preparation.

Funding

The authors received no financial support for the research, authorship, and publication of this article.

Conflict of Interest

The authors do not have any conflict of interest.

References

- Tojo, N. Prevention of Textile Waste. 2012. http://norden.diva-portal.org/s Retrieved on 24th December 2017

- Tamer, F. K. Mohamed, E. D. Recycling of Textiles. J Tex Sci Engng. 2014; 2: 001.

- Claudio, L. Waste Couture: Environmental Impact of the Clothing Industry. Environ Health Perspect 2007;115(9): A449–A454.

- Ross, C. What Is Zero Waste Fashion Design All About? 2017 https://theswatchbook.offsetwarehouse.com Retrieved on 26th December, 2017.

- Caulfield, K. Sources of Textile Waste in Australia. 2009. http://www.nacro.org.au Retrieved on 24th December 2017.

- Hill, R.P. Non-Biodegradable Clothes Take 20 to 200 Years to Biodegrade. 2017 Retrieved from https://edgexpo.com/ on 15th May, 2020.

- Scura, L.F. Assessing the Cost of Urban Pollution in the Latin American Region: The Role of Economic Valuation. 1991; 30.

- Weerakoon, T. C. T. Pilapitiya', S. C. Kotagarna, H. B. Senanayake, Y. D. A. A Study on Generation and use of Solid Waste in the Garment Industry. Tropical Agril Res. 1996; 8: 262-272.

- Velmurugan, J. S. Ramaraj, B. G. A bird view of waste management in garment industry special reference to tirupur district. Asia Pacific J Res. 2014; 1(11): 169.

- Guner, M. Yucel, O. Environmental Protection and Waste Management in Textile and Apparel Sectors. J App Sci. 2005; 5: 1843-49.

- Raha, S. B. Waste Management in Garment Industries. 2012. https://www.slideshare.net Retrieved on 24th December, 2017.

- Yen, J. The Creation of Waste-Free Garments. 2016. https://www.seamwork.com/ Retrieved on 27th December, 2017.

- Rissanen, T. Zero – waste fashion design: A study at the intersection of cloth, fashion design and pattern cutting. 2013. Doctoral dissertation. Sydney University of technology.

- Mc Quillan, H. Rissanen, T. Yield making fashion without making waste. 2011. http://www.acadmia Retrieved on 28th December, 2017.

- Ciabailey, S. Can textile waste be eliminated from the fashion industry? 2014. http://rippedthreads.wordspress.com Retrieved on 24th December, 2017.

- Miinimaki, K. Sustainable fashion new approaches. 2013. Aalto university series, 9/2013 Aalto ARTS Books Helsinki, Finland.

- Elradi, W. A. The concept of Zero waste fashion and macramé technique to boost up the innovation of women garments designs inspired by Nubian motifs. Int Design J. 2016; 6(1).

- Miinimaki, K. Zero waste fashion pattern cutting workshops. Aalto university series, 8/2012 retrieved from http://balticticfashion.eu. On 2nd January, 2018.

- Rosenbloom, S. Fashion tries on zero – waste design. 2010. http://nytimes.com Retrieved on 28th December, 2017.

- Roberts, J. Subtraction pattern cutting with Julian Roberts. 2011. http://academiaedu Retrieved on 25th December, 2017.

- Elena, Z. "Zero – waste" Absolute simplicity. 2014. http://elenaworkshop.blogspot.com/ 2014/02/zero-waste-experimentaldraping.html. Retrieved on 25th December, 2017.

- Rinehart, K. The concept of Zero waste fashion & macramé technique to boost up the innovation of women garments. Intl Design J. 2012; 6(1):328.

- Valtas A, Sun D (2016) 3D Printing for Garments Production: An Exploratory Study . J Fashion Technol Textile Eng 4(3)1-4.

- December, 2017.rd25. Redress. "The Eco chic Design Award Zero – waste Design Technique". 2013. http://ecochicdesignaward.com Retrieved on 23

- 2014 5(1) 1159 -60.Int J Sci Engng Res24. Jaggal S, Garg P and Kumar A. Seamless (Fully fashioned) clothing their Advantages, Disadvantages, Applications and Design Possibilities.

- Bairagi, N. Recycling of Textiles in India. J Textile Sci Engng.2014; 2: 003.

- Handique, M. Old clothes spin a new yarn in India. 2010. www.livemint.com Retrieved on 27th December, 2017.

- Rani S and Jamal Z. Recycling of textiles waste for environmental protection Int J Home Sci 2018; 4(1)164-168.

- Kumari, R. Quazi, T. Z. Kumar, R. Application of Lean Manufacturing Tools in Garment Industry. Int J Mech Engn Info Tech. 2015; 3 (1): 976-82.

- Anonymous. Lean manufacturing in apparel industry. 2016. http://www.apparelscience.com Retrieved on 27th December, 2017.

- Cruz H, Broega A. C and Amorim M. Sustainability in Fashion: A Study of Clean Waste Management within a Clothing Company Retrieved from https://repositorium.sdum.uminho.pt/b on 14th May, 2020.

- Aishwariya S. Waste Management Technologies in Textile Industry. Innov Ener Res 2018; 7(3)211.