Monitoring and Evaluation of Whole-Body Vibration Exposure of Equipment Operators and Assessment of Associated Health Risk in An Indian Underground Pb-Zn Mine

Bibhuti Bhusan Mandal1

, Shivkumar Shrinarayan Prajapati2

*

, Shivkumar Shrinarayan Prajapati2

*

, Syed Aftab Hussain2

, Syed Aftab Hussain2

and Rahul Anup Mishra2

and Rahul Anup Mishra2

1

Department of Mining Engineering,

Indian Institute of Technology,

Kharagpur,

721302

India

2

Department of Occupational Hygiene,

National Institute of Miners Health (NIMH), Autonomous Body Under Ministry of Mines, Government of India,

JNARDDC Campus, Amravati Road,

Wadi Nagpur,

440023

India

DOI: http://dx.doi.org/10.12944/CWE.13.3.13

Copy the following to cite this article:

Mandal B.B, Prajapati S. S, Hussain S. A, Mishra R. A. Monitoring and Evaluation of Whole-Body Vibration Exposure of Equipment Operators and Assessment of Associated Health Risk in An Indian Underground Pb-Zn Mine. Curr World Environ 2018;13(3). DOI:http://dx.doi.org/10.12944/CWE.13.3.13

Copy the following to cite this URL:

Mandal B.B, Prajapati S. S, Hussain S. A, Mishra R. A. Monitoring and Evaluation of Whole-Body Vibration Exposure of Equipment Operators and Assessment of Associated Health Risk in An Indian Underground Pb-Zn Mine. Curr World Environ 2018;13(3). Available from: https://bit.ly/2PQgXel

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2018-11-12 |

|---|---|

| Accepted: | 2018-12-18 |

| Reviewed by: |

Adérito Seixas

Adérito Seixas

|

| Second Review by: |

Nasser Najibi

Nasser Najibi

|

| Final Approval by: | Dr. Gopal Krishan |

Introduction

Whole-body vibration (WBV) is transmitted to the human body as a whole through supporting surfaces such as feet, buttocks and back.1 Exposure to WBV at work is linked to adverse effect on human health, discomfort and perception among others. Several factors are responsible for intensity of exposure to WBV arising from heavy earth moving equipment operators. These include machine related factors (vehicle type, design, age, condition of vehicle, suspension, seat arrangement, engine condition, speed), personal factors (operator’s age, body mass index, health issue and habits) and environmental factors (road conditions, geo-mechanical characteristics).Some studies report the influences of job related factors such as work organisation, task design and working conditions2–6

According to the epidemiological researchers, long period of exposure to WBV causes pain in low back and lumbar spine along with inter-vertebral disc disorders.7-9 A pilot study conducted among dumper operators in India revealed that their operators had pain symptoms in low back (85%), knee (7.8%) and shoulder (30%) respectively. All these operators were exposed to vibration at work for more than five years.10 Even though low back pain is a common occupational disease for mining personnel, still the connection between exposure to whole body vibration and low back pain is not fully understood. Kjellberg et al., still supported to conclude that there's most likely an association between WBV and LBP. However, it's almost impossible, on the basis of existing literature, to determine whether or not WBV-exposure as such is capable of causing LBP, or if WBV constitutes a risk only in combination with different factors, like prolonged sitting and certain work postures.22

International Labour Office recommended that ‘Measures have to be taken against vibration for the protection of employees; in-charge of the department has to enforce criteria to limit the risk’.11,12 The Directorate General of Mines Safety (DGMS) in India has also recommended for implementation of several steps which would ensure desirable degree of comfort and protection against whole-body vibration in mines. Recommendations of 10th Conference on Safety in Mines held in India states that ‘vibration studies must be conducted in every mining equipment before they are introduced to mining operations as per ISO Standards’.13

Many underground mines in India are well mechanised that regularly deploy heavy machinery for mining and transport of ore and waste. Other utility vehicles are used for allied services like carrying mine employees (personnel carrier), maintenance of haulage roads (motor grader), supply of explosives or transportation of backfilling material etc.

A variety of field investigations have been reported on vibration exposure in underground mining equipments abroad.14-16 All the research articles on whole-body vibration published from India dealt with the open cast mine only. This is the first study which aims to characterize the whole-body vibration arising from operation of Low Profile Dump Trucks (LPDT), Load Haul Dumpers (LHD), and other utility vehicles in underground mine. It also highlights the variation in nature of exposure to vibration emanating from these machines according to their operating speed, seat arrangement, seat suspension and work practices of the operators.

Material and Method

Mining Method

The present study was conducted in a Pb-Zn underground mine in western India where mining is carried out by open stoping or Mathew’s method. For upper section of the ore body having thinner & steeply dipping ore body, longitudinal long hole open stoping (LHOS) has been adopted. In a later period, transverse long-hole open transverse stoping (TLHOS) mining method is planned in lower section of the mine, where ore body is thicker & shallow dipping. Mining operation is integrated with back filling of mined out voids using rock fill (RF) and/or cemented rock fill (CRF).

Mine Development

The mining activity has commenced since 2011. During the first two years, only mine development works were carried out and there was some incidental ore production. Mine production commenced from the third year onwards. Deep drilling is carried out with drill machines appropriate to the mine’s requirement. Emulsion explosive is used in blasting of ore which is taken to the face by charge carrier. Blasted materials are excavated and transported by combination of LPDT and LHD. These material is loaded on 30/50 tonnes LPDT with the support of LHD. Machines used in all these developmental and ore production in the mine transmit vibration to their operators.

The mine operates in three shifts starting from a) 8:00AM to 4:00PM, then b) 4:00PM to 12:00AM and again from c) 12:00AM to 8:00AM. About 100 miners were working per shift during the study. Vibration sources in this mine mainly include machines such as LPDT, LHD, Explosive charge carrier, water sprinkler, utility vehicle, underground motor grader, Millar (used for transportation of backfilling materials) and personnel carrier. Number of machines and utility vehicles to be deployed in any day depends on the daily production target fixed by the company which usually does not vary widely during a year. The study was designed considering the average daily deployment of mining machinery in the mine during July 2016 which is shown below (Table I).

Table 1: Inventory of Mining Equipment

| Equipment | Nos. | Make | Motive Power, HP |

| Loading Machines | |||

| Load Haul Dump (LHD) | 4 | Sandvik | Diesel, 388 HP |

| Load Haul Dump (LHD) | 1 | Atlas Copco | Diesel, 250 HP |

| ST 1030 | |||

| Load Haul Dump (LHD) | 1 | Sandvik | Diesel, 268 HP |

| Hauling Machines | |||

| Low Profile Dump Truck (LPDT)50T | 2 | Atlas Copco | Diesel, 650 HP |

| Low Profile Dump Truck (LPDT)30T | 2 | Atlas Copco | Diesel, 400 HP |

| Low Profile Dump Truck (LPDT)30T | 2 | Sandvik | Diesel, 400 HP |

| Utility Vehicles | |||

| Underground motor grader | 1 | Caterpillar | 129 |

| Personnel Carrier | 2 | Normet | 129 |

| Drilling Machines | |||

| Drill Jumbo DD321-40 | 1 | Sandvik | 147 |

| Boomer B282 | 5 | Atlas Copco | 78 |

Selection of Equipment

This underground Pb-Zn mine is fully mechanized and produces about 1500 Tonnes per shift. Twelve mining equipment were studied for whole-body vibration (Table II) which included almost all the major categories of machines used in the mine depending on their availability for our research. Since the operators of the drill machines were running the drills in a standing posture using control levers, such machines were excluded from this study. It may be noted that WBV transmitted through feet and its probable effects are not well described in ISO 2631-1:1997.17 The current study deals with contact to vibration in seated posture. Seats of all the machines studied here had adjustment mechanism.

Table 2: List of equipment studied for whole-body vibration

| Equipment | Equipment No. | Make | Capacity | Route of vibration exposure | Seat Type |

| Hauling Machines | |||||

| LPDT | T1 | Atlas Copco | 30 TON | Through seat baseand feet | Spring – Cushion |

| LPDT | T2 | Sandvik | 30 TON | Through seat base and feet | Spring – Cushion |

| LPDT | T3 | Sandvik | 30 TON | Through seat base and feet | Spring – Cushion |

| LPDT | T4 | Atlas Copco | 30 TON | Through seat base and feet | Spring – Cushion |

| Loading Machines | |||||

| LHD | L-1 | Sandvik | 6 yard haulage | Through seat base and feet | Spring – Cushion |

| LHD | L-2 | Sandvik | 6 yard haulage | Through seat base and feet | Spring – Cushion |

| Utility Vehicles | |||||

| Underground motor grader | RG1 | Caterpillar | 225 HP | Through seat base and feet | Spring – Cushion |

| Explosive charge carrier | C1 | NORMET | - | Through seat base and feet | Spring – Cushion |

| (Charmec) | |||||

| Utility Vehicle | U1 | NORMET | - | Through seat base and feet | Spring – Cushion |

| Millar (used for transportation of backfilling materials) | M1 | NORMET | 3.5 TON | Through seat base and feet | Cushion |

| Personnel Carrier | PC1 | NORMET | 32 Seater | Through seat base and feet | Spring – Rubber |

| Water Sprinkler | WT1 | NORMET | 4 TON | Through seat base and feet | Massive |

Materials and Methods

Instrumentation

The whole-body vibration study was so planned and executed that it did not disturb or interfere the routine operations in the shift. Each operator was explained about the purpose of the measurement before taking the readings.

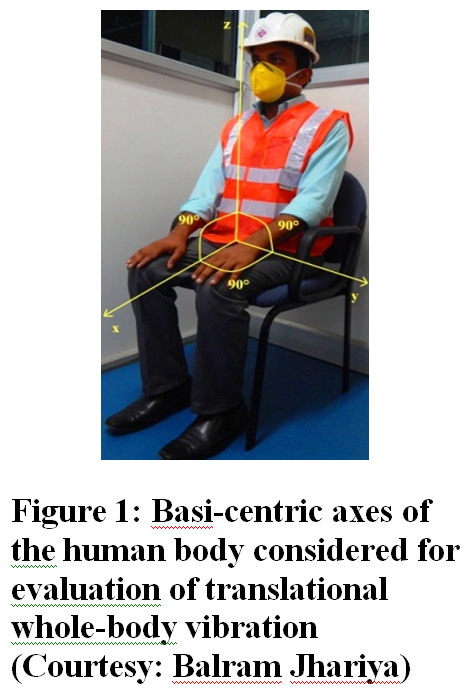

As mentioned in ISO 8041:2005 & ISO 2631-1:1997,17,18 the seat pad accelerometer was placed below the ischial tuberosities (buttock) of the operator i.e. at the interface between the seat (source of vibration) and the body part of the operator directly being affected. The integrated electronic piezo-electric (IEPE) tri axial seat pad accelerometer was placed in such a manner that the axis diagram printed on the seat pad surface was aligned to the right handed orthogonal coordinate system according to ISO 5805:19971 (Figure 1). SV 106A Human Vibration Meter & Analyser, (manufactured by SVANTEK, Poland)was connected to the seat pad accelerometer through transmission cable (Figure 2). The following parameters were measured: a) frequency weighted root mean square (r.m.s.) acceleration value denoted by aw, b) peak acceleration, linear crest factor and vibration dose value (VDV). The signal transmission cable was placed safely to avoid any interference with the operations.

|

Figure 1: Basi-centric axes of the |

|

Figure 2: Seat pad Accelerometer |

Vibration Evaluation

Basic assessment of vibration magnitude using root mean square (r.m.s.) acceleration

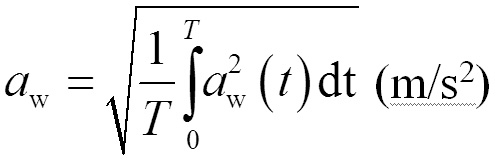

According to ISO 2631-1:1997 Standard, the measurement of magnitude of vibration is to be carried out in three orthogonal (mutually perpendicular) axes (x, y and z) expressed in terms of frequency-weighted root mean square (r.m.s.) acceleration values. The weighted r.m.s. acceleration is expressed in ms-2. The weighted r.m.s. acceleration (aw) is to be measured in accordance with the following equation:

...[1]

...[1]

Where,

aw(t) = Frequency weighted instantaneous acceleration at timet and

T = Period of measurement in seconds

The frequency weighted r.m.s acceleration value was individually (i.e. separately for x, y and z) multiplied by a scale factor (k) before determining the dominant axis of vibration (kx,ky = 1.4, kz = 1).

Crest Factor (CF)

As mentioned in ISO 2631-1:1997 (sub-clause 6.2.1), linear crest factor is defined as the ratio of frequency weighted peak acceleration value to its r.m.s acceleration value. It may be used to examine the applicability of further evaluation methods which is more sensitive to impulsive shocks. Basic evaluation method is normally sufficient for crest factor below or equal to 9. If crest factor is greater than 9, then further evaluation should be carried out.

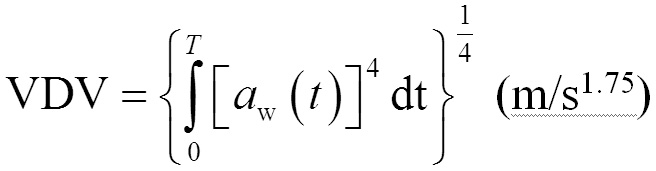

Vibration Dose Value (VDV)

Vibration dose value (VDV) is used for assessment of health risk where crest factor is greater than 9. VDV is based on the fourth power of acceleration values and more sensitive to peaks (impulsive vibration signals).

...[2]

...[2]

Where,

aw(t) = Frequency weighted instantaneous acceleration at timet and

T = Period of measurement (s).

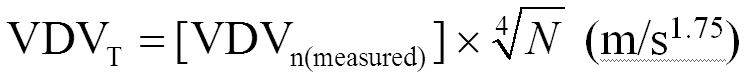

Total Vibration Dose Value (VDVT)

As required in sub-clause 6.3.2 of ISO 2631-1:1997, total vibration dose value (VDVT) should be calculated when the vibration exposure consist of different magnitude i.e. two or more periods. Total vibration dose value (VDVT) is based on fourth root of the sum of the fourth power of individual vibration dose values:

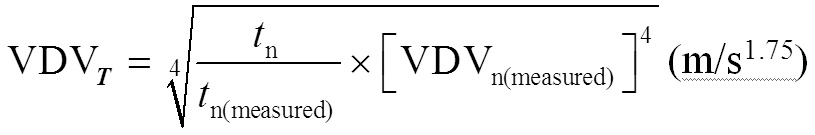

...[3]

...[3]

Calculation of VDVT in non-cyclic and cyclic operations

VDV is limited to the duration of measurement, which needs to be scaled up to represent daily exposure. In cyclic operation or repetitive operation like to and fro movement of LPDT for loading and unloading, the total Vibration dose value (VDVT) for the entire shift can be expressed by Mandal et al.,19

...[4]

...[4]

Where,

VDVT = Total vibration dose value,

VDVn(measured) = Vibration dose value measured for n number cycle of operation and

N = Number of trips in a day (for LPDT and similar equipment).

As mentioned in clause 6.3.2 of ISO 2631-1:1997, the above expression was derived for evaluating total exposure where a series of exposure periods (trips) were involved. In non-cyclic operation (e.g. for LHDs), VDV was calculated for a lesser period of time representing routine work as a basic value. Subsequently, total VDV was computed for the total period of exposure in a day by Mandal et al.,19

...[5]

...[5]

Where,

VDVn(measured)= Vibration dose value for the duration of measurement,

tn(measured)= Duration of measurement,

tn = Average duration of exposure per day and

VDVT = Total vibration dose value.

Duration of measurement and vibration exposure

In case of cyclic operations, a complete trip/cycle was recorded for the vibration exposure level (e.g., LPDT which included loading, hauling, unloading and returning to the loading point. Number of trips is multiplied with time taken per cycle to evaluate total duration of exposure in an 8 hours shift as shown below

T = (N * t)/3600 ...[6]

Where,

N = Number of trips per shift

t = Time taken for one complete cycle (loading and Unloading) in secs

T = Total duration of exposure in hours.

A minimum 15 minutes reading was taken for operations which are not very specific (e.g., for Load Haul Dumper (LHD). The duration of exposure was collected from mine officials or it was determined by time or motion study. For example, three LPDTs were allocated for each LHD for the routine work. According to that average loading time of a LHD on to a LPDT was measured during the repeated loading operations. Meanwhile, LHDs will do mucking and other material handling work for face preparation or even clearing the approach roads (drives or cross-cuts) by lowering its bucket and pushing away the debris. This additional work was taking about 20% more time before the next loading job started. This data was used to find out operating hours as follows.19

...[7]

...[7]

Calculation for LHD (example)

T = 1.2(900*3*8)/3600 = 5.76 hrs

Where,

t = Average time taken in seconds by a LHD for loading a LPDT,

N = No. of LPDTs catered by a LHD,

C = No. of trips made by a LPDT in a shift,

T = Total duration of exposure in hours.

Effects of vibration on health of operators

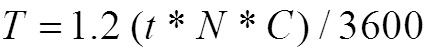

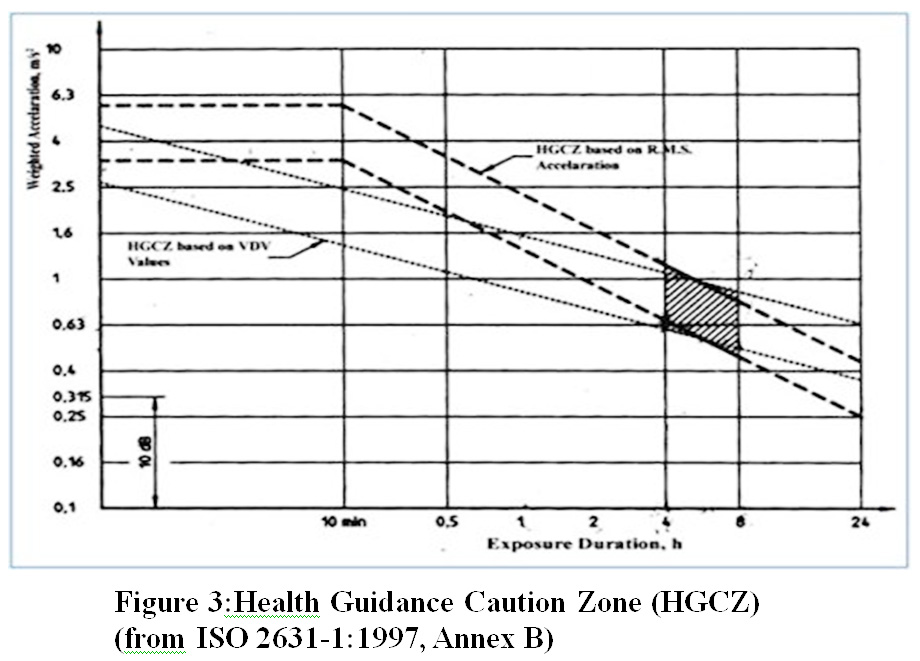

Following ISO 2631-1(1997), graphical representation of health guidance caution zone (HGCZ) has been used for evaluation of exposure risk (Figure 3). The area between a set two parallel lines related to lower and upper limits which describes about HGCZ. In that graph, we can see two such sets. The first one uses the duration of exposure and acceleration magnitude in RMS values (aw) in x and y coordinates respectively to determine the severity of exposure. Health risk evaluation of a point P (x, y) plotted using duration of exposure in a day (x-axis) and the corresponding magnitude of vibration (y-axis) was carried out according to the location of the point with reference to the upper and lower boundaries of the caution zone. Exposure below the HGCZ has been termed as ‘minimal’ for risk assessment as health effects are not well-documented. Exposure points falling within the HGCZ boundaries have been termed as ‘moderate’ for risk assessment as there is a probability of adverse effect on health and above the zone, exposures have been considered as ‘high’ in risk assessment procedure as there is a significant risk of adverse health effects.

The second set of parallel lines forms HGCZ based on VDVT, which has upper and lower bounds at 8.5 and 17 m/sl.75, respectively. VDVT values are derived and risk analysis is carried out in addition to the basic evaluation using aw values where linear crest factor (CF) was equal to or more than nine. Linear crest factors were calculated by dividing the peak acceleration value by the corresponding r.m.s. values of acceleration.

|

Figure 3: Health Guidance Caution Zone (HGCZ) (from ISO 2631-1:1997, Annex B) |

Results

Table 3 shows risk assessment of vibration exposure using r.m.s. acceleration values of different equipment operators. Among twelve mining equipment, six of the equipments have z axis as dominant axis of vibration, two of the equipment operator have y axis as dominant axis of vibration and similarly, four of the equipment have x axis as dominant axis of vibration.

Evaluation of Health Risk of Operators

It was observed that LPDT no T2, T3 had y axis as the dominant axis of vibration with their operators being exposed to a moderate health risk; LPDT no T1 had z axis as the dominant axis with its operator being exposed to a moderate health risk. Similarly, LPDT no T4 had x axis as the dominant axis with its operator being exposed to moderate health risk through WBV exposure. It was observed that r.m.s. acceleration value fell between 0.46 to 0.79 m/s2 (Table 3). Additional evaluation was carried out on LPDT no T1 and T4 to find out VDVT. VDVT values (10.91 and 18.16 m/s1.75) revealed that operators were being exposed to a high and moderate health risk respectively (Table 4).

Basic evaluation was carried out on two LHDs. It was observed that LHD L1 and LHD L2 had x axis as dominant axis with aw values being 0.77 and 1.01 m/s2. The operators were exposed to moderate health risk (Table 3). Only LHD L2 had crest factor greater than 9. So, additional evaluation was carried out. It shows VDVT value as 14.69 m/s1.75 with their operator exposed to minimal health risk using HGCZ (Table 4).

Underground motor grader (RG1) had r.m.s acceleration value of 0.62 m/s2 along x axis which was dominant axis of vibration. The operator was exposed to minimal health risk as per HGCZ when considered with the duration of exposure.

Charmec (C1) (emulsion explosive charge carrier) had z axis as the dominant axis of vibration. It has the r.m.s acceleration value of 0.55 m/s2. The operator was exposed to moderate health risk.

One 32-seat personnel carrier (PC1) is used for transport of operators and others to the work site. It showed z axis as the dominant axis of vibration using basic evaluation criteria which had the r.m.s. acceleration value of 1.00 m/s2. Additional evaluation shows VDVT value as 22.27 m/s1.75 (Table 4)

The highest magnitude of vibration was found as 1.30, 1.77 and 1.96 m/s2 in water tanker (WT1), utility vehicle (U1) and Millar (M1) (used for transportation of backfilling materials) respectively. All of them had z axis as the dominant axis of vibration exposure.

Table 3: Risk Assessment for Vibration Exposure Using r.m.s Values (n = 12)

| S No | Equipment Name & Number | Axes of Vibration | aw (m/s2) | Adjusted aw(m/s2) by scale factor k* | Dominant Axis | Duration of exposure (hrs) | Health Risk (by HGCZ) |

| 1 | LPDT – T1 | x | 0.38 | 0.53 | z | 6 | Moderate |

| y | 0.38 | 0.53 | |||||

| z | 0.79 | 0.79 | |||||

| 2 | LPDT – T2 | x | 0.33 | 0.46 | y | 6 | Moderate |

| y | 0.44 | 0.62 | |||||

| z | 0.52 | 0.52 | |||||

| 3 | LPDT – T3 | x | 0.37 | 0.52 | y | 6 | Moderate |

| y | 0.47 | 0.66 | |||||

| z | 0.46 | 0.46 | |||||

| 4 | LPDT – T4 | x | 0.46 | 0.64 | x | 6 | Moderate |

| y | 0.38 | 0.53 | |||||

| z | 0.63 | 0.63 | |||||

| 5 | LHD-L1 | x | 0.55 | 0.77 | x | 5.76 | Moderate |

| y | 0.47 | 0.66 | |||||

| z | 0.59 | 0.59 | |||||

| 6 | LHD-L2 | x | 0.72 | 1.01 | x | 5.76 | Moderate |

| y | 0.56 | 0.78 | |||||

| z | 0.86 | 0.86 | |||||

| 7 | Underground motor grader RG1 | x | 0.44 | 0.62 | x | 5 | Minimal |

| y | 0.33 | 0.46 | |||||

| z | 0.4 | 0.4 | |||||

| 8 | Personnel Carrier PC 1 | x | 0.46 | 0.64 | z | 5 | Moderate |

| y | 0.45 | 0.63 | |||||

| z | 1 | 1 | |||||

| 9 | Water Sprinkler WT 1 | x | 0.36 | 0.5 | z | 5 | High |

| y | 0.43 | 0.6 | |||||

| z | 1.3 | 1.3 | |||||

| 10 | CharmecC1 (explosive charge carrier) | x | 0.31 | 0.43 | z | 5 | Moderate |

| y | 0.37 | 0.52 | |||||

| z | 0.55 | 0.55 | |||||

| 11 | Utility Vehicle U1 | x | 0.51 | 0.71 | z | 2.5 | High |

| y | 0.41 | 0.57 | |||||

| z | 1.77 | 1.77 | |||||

| 12 | Millar M1 (used for transportation of backfilling materials) | x | 0.38 | 0.53 | z | 4 | High |

| y | 0.54 | 0.76 | |||||

| z | 1.96 | 1.96 |

** Minimal, Moderate and High refers to Not Indicated, Indicated and Likely categories of health risks respectively of the ISO Standard 2631-I:1997.

Whole-body vibration (WBV) studies were carried out on a total of twelve mining machinery. The results were analyzed taking into account the corresponding duration of exposures to predict the severity of adverse health effects using ISO 2631-1:1997. It was found that six out of twelve equipments had crest factors greater than nine. So we consider additional parameter i.e. vibration dose values (VDV). Table 4 shows the risk assessment for vibration exposure using vibration dose values.

Table 4. Risk assessment for vibration exposure using VDV values (n=6)

| S No | Equipment Name and Number | Dominant Axis | Measured VDV (ms-1.75) | VDVT (ms-1.75) | Health Risk (by HGCZ) |

| 1 | LPDT – T1 | z | 10.8 | 18.16 | High |

| 2 | LPDT – T4 | x | 6.49 | 10.91 | Moderate |

| 3 | LHD – L2 | x | 4.89 | 14.69 | Minimal |

| 4 | Personal Carrier PC 1 | z | 9.73 | 22.27 | Moderate |

| 5 | Utility Vehicle-U1 | z | 18.6 | 37.97 | High |

| 6 | Millar-M1 | z | 20.2 | 41.83 | High |

Discussion

Whole-body vibration exposure in underground mines requires special attention since operations of these machines in underground mines have multiple limitations. LPDTs T1 and T4 are steering operated and the operator drives it looking straight forward towards the front. The other two LPDTs, T2 and T3 are joystick operated and the operator’s line of sight is perpendicular to the longitudinal axis of the machine. Front back vibration (x axis) was dominant in T1 and T4. But T2 and T3 both had y axis (lateral axis) as dominant axis of vibration. Since the driver’s sitting posture in T2 and T3 is at 90 degree clock-wise with respect to T1 and T4, the position of basi-centric axes of x and y has swapped their individual positions. Hence the y axis of T2 and T3 is nothing but the x axis of T1 and T4. Summarily, all the LPDTs have front to back axis (x axis) as dominant axes of vibration. The results seemed to be in contrast with dumpers in opencast mines; one study with 18 dumpers showed z axis as their dominant axis of vibration.10 The height of LPDT is low to accommodate their manoeuvring through the underground tunnel. LPDT operators must operate the equipment with limited speed; maintain continuous attention towards side mirrors and pathway to avoid clashes between external surface of LPDT and the tunnel walls of the underground mines. However, speed and style of the driving of any operator will definitely influence the changes in present amplitude of acceleration (0.64 to 0.79 m/s2). If any further deterioration of their condition is allowed to happen, all of them are likely to pose moderate to higher risk of health disorders.

Load Haul Dumper (L1 and L2) operators were both exposed to moderate health risk. Both of them were found to have x axis as dominant axis of vibration while performing tasks like tramming full, tramming empty and mucking. Our result goes well with certain previous studies on underground LHDs where x axis was the dominant axis of vibration and r.m.s. acceleration values being in the similar range of 0.53 to 1.19 m/s2as mentioned.20 LHDs are much similar with loaders in open cast mines. Therefore, the movements are predominantly in front and back direction. A previous study which was conducted on 19 loaders in open cast mines showed that 79% of them having x axis as dominant axis of vibration. The work practices of machines effectively influence emergence of any axis as dominant axis of vibration and therefore susceptibility of any body part or parts likely to be injured by vibration.21 Operation of Loader or LHDs is associated with sudden jerks and shocks. The operation of both these machines is marked by a characteristic continuous and vigorous alternation between forward and reverse motions. As a consequence, these machines are usually found to have x (front-back) axis as dominant.

As suggested in the ISO 2631-1, a health-guidance caution zone (HGCZ) defined by values of A(8) of 0.43 and 0.87 m/s² r.m.s.The A(8) values for these two LHDs (L1 & L2) are 0.63 and 0.83 m/s² respectively, hence both had moderate health risks from vibration exposure at work. If operators of these LHDs work for six hours instead of 5.76 hour in a shift, it will pose high health risk to them which means this exposure is only marginally below the upper limit of HGCZ.

Underground motor grader operator was exposed to minimal health risk. Seats are in very good condition and the machine runs very slowly. It is tyre-mounted and has to be carefully driven to save the blades from hitting the sidewalls. It should be periodically monitored to observe any deterioration that might take place over long period of time.

The operator of Charmec (explosive charge carrier) was exposed to moderate health risk using r.m.s. acceleration value of 0.55 m/s2. Seats were found in very good condition. The operators tend to drive it very fast since it has a slender body configuration. The risk might come down to minimal if it was driven slower.

Similarly, Personnel carrier operator was exposed to moderate health risk using basic evaluation as well as additional evaluation by VDVT. Presently the vehicle makes about five trips in a day and sometimes attends to additional calls as per requirement. The total travelling time will slowly increase as the mine workings goes deeper to the lower levels thereby increasing the risk of increased duration of vibration exposure further. Moreover, the vehicle seat suspension had adjustment system to control the heights which could be fine-tuned as per the body weight of the operator. The risk could be minimised if seat adjustments were carried out among other necessary precautions.

Water sprinkler operator was exposed to high health risk using acceleration value of 1.30 m/s2 and 5 hours of exposure in a shift. The vehicle makes several trips for controlling of dust in the haul roads of underground mine. It had a fixed non-adjustable seat and its condition was worst among all the equipment studied. Also the driving speed was quite high which could have been controlled by the operator to reduce his own health risk.

Utility vehicle operator was exposed to high health risk using acceleration value of 1.77 m/s2 with only 2.50 hours of exposure in a shift. Risk remained high on additional evaluation based on VDVT. This vehicle was used for carrying of equipment spares, drill rods, food and supplying of drinking water in different sector of underground mines. The condition of seat was very poor and overall maintenance of the vehicle was not up to the mark. A combination of high speed, harsh braking, poor seat condition and poor maintenance resulted in to the high health risk for the operator.

Similarly, Millar (used for transportation of backfilling materials) operators were exposed to high health risk having 1.96 m/s2 r.m.s. acceleration value and 4 hours of exposure in a shift. In fact, at such high level of vibration the health risk will remain high with only 1 hour 35 minutes of exposure in a shift which is alarming. During the study this vehicle was being driven with high speed and the condition of the haul road was also not good.

Based on the present study, the authors are of the opinion that it is imperative to reduce the severity of exposure to vibration inunderground mines by available control measures including improvement of the haul road conditions and use ofproper seat suspension for vibration isolation. Whole-body vibration may enhance overall health risk for miners who are already stressed due to a number of adverse factors arising out of subsurface work environment. However, more samples are required to clearly elicit the magnitude of the problem and above all, the awareness in this regard needs to be increased among management and workers both to promote better occupational health of mining community.

ConclusionsThis study concludes that use of LPDTs in this underground mine for loading, hauling and unloading of ore with the prevailing vibration intensity and duration of exposure pose moderate risk to their operators. With little increase in the duration of exposure or speeding of the vehicle, all the operators will have higher health risk.

Apart from LPDTs, all LHDs also had x-axis (front to back) as dominant axis of vibration. Hence apart from adjustment in vertical axis (z axis) these vehicles must have vibration absorption facilities in x direction also. These operators also have moderate health risk.

The water tanker, utility vehicle and Millar etc. had high health risk due to high operating speed in general which could have been controlled to reduce exposure risk.

Seat adjustment facilities were already available in many of the vehicles studied but the drivers were not properly informed about them. Since there is a general lack of awareness in respect of risks from exposure to vibration, awareness and training programs may be regularly organised by vocational training centres (VTC) of the mine to bring improvement in the work environment.

Acknowledgements

The authors are grateful to the Director, National Institute of Miners’ Health, Nagpur (India) for providing all necessary facilities to conduct the research as well as according permission for publication of the research article.

References

- ISO. ISO 5805:1997 Mechanical Vibration and Shock -- Human Exposure -- Vocabulary. Geneva; 1997. https://www.iso.org/obp/ui/#iso:std:iso:5805:ed-2:v1:en.

- Cann AP, Salmoni AW, Eger TR. Predictors of whole-body vibration exposure experienced by highway transport truck operators. Ergonomics. 2004;47(13):1432-1453. doi:10.1080/00140130410001712618.

CrossRef - Chen JC, Chang WR, Shih TS, et al., Predictors of whole-body vibration levels among urban taxi drivers. Ergonomics. 2003;46(11):1075-1090. doi:10.1080/0014013031000109205.

CrossRef - Tiemessen IJ, Hulshof CTJ, Frings-Dresen MHW. An overview of strategies to reduce whole-body vibration exposure on drivers: A systematic review. Int J Ind Ergon. 2007;37(3):245-256. doi:10.1016/j.ergon.2006.10.021.

CrossRef - B Mcphee FG and LA. Exposure to Whole Body Vibration for Drivers and Passengers in Mining Vehicles, Part 2, Report of Findings at Four Underground Mines. Sydney; 2001.

- Mandal BB, Mansfield NJ. Contribution of individual components of a job cycle on overall severity of whole-body vibration exposure: A study in indian mines. Int J Occup Saf Ergon. 2016;22(1):142-151. doi:10.1080/10803548.2015.1116815.

CrossRef - Hulshof C, Veldhuijzen van Zanten B. Whole-body vibration and low-back pain - A review of epidemiologic studies. Int Arch Occup Environ Health. 1987;59(3):205-220. doi:10.1007/BF00377733.

CrossRef - Helmut Seidel, Ralph Bluethnerand BH. Effects of sinusoidal whole-body vibration on the lumbar spine: the stress-strain relationship. Int Arch Occup Env Heal. 1986;57:207-223. doi:10.1080/10584580600949055.

CrossRef - Wikström BO, Kjellberg A, Landström U. Health effects of long-term occupational exposure to whole-body vibration: A review. Int J Ind Ergon. 1994;14(4):273-292. doi:10.1016/0169-8141(94)90017-5.

CrossRef - Mandal BB, Srivastava AK. Musculoskeletal disorders in dumper operators exposed to whole body vibration at Indian mines. Int J Mining, Reclam Environ. 20 doi:10.1080/17480930903526227.

CrossRef - ILO. C148 - Working Environment (Air Pollution, Noise and Vibration) Convention, 1977 (No. 148). https://www.ilo.org/dyn/normlex/en/f?p=NORMLEXPUB:12100:0::NO::P12100_ILO_CODE:C148. Published 1977. Accessed January 28, 2018.

- ILO. R156 - Working Environment (Air Pollution, Noise and Vibration) Recommendation, 1977 (No. 156). https://www.ilo.org/dyn/normlex/en/f p=NORMLEXPUB:55:0:::55:P55_TYPE,P55_LANG,P55_DOCUMENT,P55_NODE:REC,en,R156,/Document. Published 1977.

- DGMS. Recommendations of 11th conference on Safety in Mines held on 4th & 5th July, 2013 at New Delhi. In: Recommendations of 11th Conference on Safety in Mines. New Delhi; 20 http://www.dgms.net/Recommendation of 11th safety conference,9.7.13.pdf.

- Eger T, Smets M, Grenier Sylvain. Whole-Body-Vibration Exposure Experienced During the Operation of Small and Large Load-Haul-Dump Vehicles. 2004:6-10.

- Mayton AG, Jobes CC, Ambrose DH, Kittusamy NK. Whole-body vibration exposure comparison of seat designs for low- andmid-seam shuttle cars in underground coal mines. Trans Soc Min Met Explor. 2010;326:132-142. https://www.cdc.gov/niosh/mining/UserFiles/works/pdfs/wbvec.pdf.

- Village J, Morrison JB, Leong DKN. Whole-body vibration in underground load-haul-dump vehicles. Ergonomics. 1989;32(10):1167-1183. doi:10.1080/00140138908966888.

CrossRef - ISO. ISO 2631-1:1997 Mechanical Vibration and Shock -- Evaluation of Human Exposure to Whole-Body Vibration -- Part 1: General Requirements. Geneva; 1997. https://www.iso.org/obp/ui/#iso:std:iso:2631:-1:ed-2:v2:en.

- ISO. ISO 8041:2005 Human Response to Vibration -- Measuring Instrumentation. Geneva; 2005. https://www.iso.org/obp/ui/#!iso:std:30145:en.

- Mandal, Bibhuti B. AKP and PKS. Vibration characteristics of mining equipement used in Indian mines and their vibration hazard potential. Int J Environ Health Eng. 2013;2(4):14-22.

- Eger T, Kociolek A, Dickey J. Comparing Health Risks to Load-Haul-Dump Vehicle Operators Exposed to Whole-Body Vibration Using EU Directive 2002/44EC, ISO 2631-1 and ISO 2631-5. Minerals. 2013;3(1):16-35. doi:10.3390/min3010016.

CrossRef - Mandal BB, Sarkar K, Manwar V. A study of vibration exposure and work practices of Loader and Dozer operators in opencast mines. Int J Occup Saf Heal. 2012;2(2):3-7. doi:10.3126/ijosh.v2i2.6144.

CrossRef - Lings S, Leboeuf-Yde.Whole body vibration and low back pain : a systmatic, critical review of the epidemiological literature 1992-1999s. Int Arch Occup Environ Health 2000; 73:290-297