Solanum Tuberosum Supplementation for Biogas Production

Pradip B. Acharya1 * and Prateek Shilpkar1

DOI: http://dx.doi.org/10.12944/CWE.10.1.35

Copy the following to cite this article:

Acharya P. B, Shilpkar P. Solanum Tuberosum Supplementation for Biogas Production. Curr World Environ 2015;10(1). DOI:http://dx.doi.org/10.12944/CWE.10.1.35

Copy the following to cite this URL:

Acharya P. B, Shilpkar P. Solanum Tuberosum Supplementation for Biogas Production. Curr World Environ 2015;10(1). Available from: http://www.cwejournal.org/?p=8351

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2014-11-04 |

|---|---|

| Accepted: | 2015-01-30 |

Biogas technology is well known in the world for waste utilization. Wastes are being converted in biogas digester anaerobically by different groups of bacteria into valuable manure and gas is generated. The gas is used for a number of purposes. Factors affecting microbial activity governs the amount of biogas generated. Rate of microbial activity fluctuates with change in pH, temperature, nutrients supply, mineral contents etc. In India since the population of cattle is very large so biogas is being generated mainly by animal dung but the fact is that being a digested product it supplies lower amount of nutrients to microorganisms than any undigested one. Fruit and vegetable wastes can be used for biogas production.1 Potato (Solanum tuberosum) is king of vegetables and remains present in almost each and every house, restaurants, hotels etc. A lab study was undertaken with objective to find out the suitability of potato addition with dung for biogas production.

Materials and Methods

Six sets were prepared each containing one 5L capacity glass digester bottle, one 2L capacity gas holder glass bottles and one 2L water displacement glass bottle, all remains connected with each other without any leakage. Digester has an outlet for discharge of digested slurry to maintain the level of feeding material in it. All the digesters were filled with mixture of 40g buffalo dung with 80mL water added daily. After 40th day when the digesters filled with outlet level this feeding remains continue for next 10 days with an equal amount of slurry discharge to maintain the level of feeding material inside digesters and with a recording of biogas produced daily by water displacement method. When the gas production becomes stable from 51th day this feeding remains continue in three control digesters whereas in remaining three test digesters feeding of 20g dung, 20g boiled potato and 80mL water started till next 30 days. The biogas production was recorded daily.

Results And Discussion

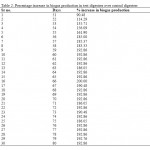

Data about daily biogas production from 51th to 80 days of experimentation show that in control digesters the average biogas production varies between 2000 and 2150 mL per day and in test digesters its average value was between 4000 and 6150 mL per day (Table 1). The total biogas production in control digesters during 80 days was 65000 mL but in test digesters total biogas production was almost 2.75 times higher i.e. 179000 mL. A close examination of data presented in Table 1 show that in test digesters biogas production ranged between 4000 and 5000 mL per day during 51st to 53rd day which increases with time and ranged between 5000 and 6000 mL per day during 54th and 58th day and then remains higher than 6000 mL per day till 80 days. Near the end of experimentation period the biogas production in control and test digesters remains constant. When this increased biogas production in test digesters over control digesters was converted in terms of percentage then it ranged between a minimum of 90.48 and a maximum of 192.86% (Table 2). As stated earlier that potato is a rich source of carbohydrate starch. After boiling this carbohydrate becomes available to microorganisms. When this boiled potato was added in digesters the ready supply of carbohydrates to microorganisms causes a burst in microbial activity and at first day of addition it shows 90.48% higher biogas production than control. With time the supply of nutrients continuous to increase with a simultaneous increase in microbial activity and biogas production too. Our results are in tune with previous work reported pre-treatment of waste increases biogas production.2-4

|

Table 1: Average biogas production obtained by addition of boiled potato at the rate of 5.3% along with dung (mL/days) Click here to View table |

|

Table 2: Percentage increase in biogas production in test digesters over control digesters Click here to View table |

Conclusion

The study concludes that addition of boiled potato in equal proportion of dung after initial filling of digester with dung resulted in continuous and sustainable increase in biogas production and produces 2.75 times higher biogas.

Acknowledgment

We are hearty thankful to Prof. S.R. Dave, Head, Microbiology & Biotechnology Department, Gujarat University, Ahmedabad, Gujarat for providing continuous academic support and guiding to conduct this research successfully.

References

- Mataalvarez J, Mtzviturtia, A., Llabresluengo P. and Cecchi, F. Biomass Bioenergy, 5 (6): 481–488. (1993)

- Chandra, R, Takeuchi, H., Hasegawa, T and Kumar, R. Energy, 43 (1): 273-282 (2012)

- Ma, J., Duong TH, Smits M, Verstraete W, and Carballa M. Bioresource Technol, 102 (2): 592-599, (2011)

- Zheng, Yi, Zhao, J., Xu F., Li Yebo. Progress in Energy and Combustion Science, 42: 35-53 (2014)